Volvo Trucks North America is preparing for production of its updated 2017 powertrain at the Hagerstown, MD powertrain manufacturing facility. The site, which assembles the company's full line of proprietary engines and I-Shift automated manual transmissions, will produce Volvo’s updated powertrain beginning in late 2016.

“The success of Volvo’s proprietary powertrain components is a direct result of the Hagerstown facility and its distinctive combination of powertrain engineering and manufacturing in one campus,” said Gӧran Nyberg, president of Volvo Trucks North America. “These unique capabilities had a significant impact on the development of our updated 2017 powertrain, which will no doubt further our leadership in integrated powertrain technology.”

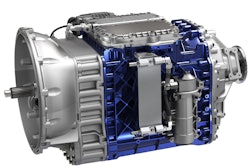

The 2017 powertrain has been engineered to increase fuel efficiency, productivity, reliability, packaging, comfort and uptime. Enhancements include revisions to the Volvo D11 and D13 engines; an all-new Volvo D13 with turbo compounding; significant updates to the Volvo I-Shift; and a new transmission option – the I-Shift with Crawler Gears – designed to improve startability and enable low-speed capabilities for applications like curb pouring and paving.

Volvo Trucks Unveils New Automated Manual Transmission Plus Engine Enhancements

“Hagerstown possesses the latest manufacturing capabilities, and our people are our No. 1 asset when it comes to producing high-quality powertrain components,” said Pierre Jenny, vice president of powertrain production. “With assembly of Volvo’s updated 2017 powertrain beginning later this year, we look forward to continuing to deliver the engines and transmissions our customers depend on.”

Since its acquisition in 2001, more than $350 million has been invested into the Hagerstown plant to modernize the facility, establish new research and production capabilities, and improve manufacturing processes. These investments have transformed the site into one of the world’s most advanced powertrain research and manufacturing facilities.

Recent investments include $30 million to upgrade the engine assembly process for improved efficiency, as well as an $8 million investment that brought production of the Volvo I-Shift to Hagerstown through the creation of a new assembly line, installation of new equipment and tooling, and employee training.

The Hagerstown site has also made great strides toward improving its energy efficiency. In 2014, the site was named a Superior Energy Performance Platinum-Certified Partner, the highest level in the U.S. Department of Energy (DOE) program. The site also participates in the DOE’s Better Buildings, Better Plants program, which has a target to reduce energy intensity by 25 percent over a 10-year period.

In 2015, the Hagerstown site partnered with ConEdison Solutions and Entropy Solar Integrators on the design and installation of a 5,000-panel solar canopy, which is among the largest on the U.S. east coast. Covering the plant’s entire north parking lot, the solar canopy generates 1.3 megawatts of electricity that is delivered directly to the facility, helping to offset the plant’s electrical demand.

![[Video] Volvo Trucks - VHD Series](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/01/default.56a0ffde0f6e9.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)