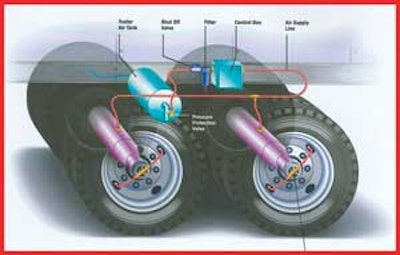

Onboard tire inflation systems allow you to continuously change or maintain tire pressures. There are actually two types of systems on the market — central tire inflation and continuous tire inflation. The continuous tire inflation systems maintain the proper tire pressure and are commonly used on trailers. The central tire inflation systems, however, allow the tire pressure to be increased or decreased. They are commonly used in vocational-type applications or straight trucks.

Initially developed for the military to increase the mobility of vehicles on soft and poor traction surfaces, operators can use central tire inflation to match tire pressures with the load and speed of the vehicle.

Going beyond price

While the initial purchase price of these systems can be intimidating, the payback comes quickly. Under-inflated tires quickly build up excessive heat while travelling down the road, resulting in dramatically shortened tire life. Conversely, decreased tire pressures allow larger footprints on the ground so trucks can traverse soft terrain without getting stuck. Both of these performance advantages can be exploited with a central tire inflation system.

The purchase price will vary with the capabilities of the system and the overall design. "The vehicle OEM ultimately determines the purchase price of a system, with our's generally starting at $8,000," says Jim Beverly, chief engineer, Commercial Vehicle Systems Group, Dana Corp. "Paybacks can be had quickly, depending on the applications. These usually come about due to reduced maintenance, the ability to haul larger payloads and a lower purchase price when you compare it to an all-wheel-drive system."

Trailer-mounted continuous tire inflation systems, on the other hand, pay for themselves by keeping trailer tires properly inflated. ArvinMeritor and Pressure Systems International claim that 80% of fleet tire problems are caused by improper inflation. A 20% under inflation of your trailer tires can cut their usable life by 25%. So there are real potential cost savings by using a continuous tire inflation system to keep the pressure constant.

Barry Eckel, director, global sales and marketing for ArvinMeritor, explains, "The additional stress of an under inflated tire will cause the rubber temperature to increase, and heat is a tire's worst enemy. As the tire gets hotter, there is an increase in tire wear. The Meritor Tire Inflation System by PSI is an automatic and continuous tire inflation system designed as both a robust and a ‘keep it simple' system. It keeps tires always running at the specified air pressure to significantly reduce annual tire operating expenses and tire-related downtime."

Gregg Alvarez, Airgo Systems, adds, "The cost of a tire for this type of equipment can run anywhere from $150 to $400 per tire. The cost of a roadside repair typically runs over $400. [In the case of Airgo] these systems can pay for themselves by saving one tire and one roadside repair. If you lose, on average, more than one tire per vehicle per year, that is money in your pocket."

Low traction applications

Flotation is a major advantage on the jobsite. "Central tire inflation offers the benefit of increased traction and flotation on the jobsite without the cost and maintenance of an all-wheel-drive configuration," says Matt Stevenson, manager of product strategy, Sterling Truck Corp. "When compared to a regular 6x4 configuration, mobility is increased with the ability to get into sandy low traction areas and, most importantly, to get out."

Sterling uses the Dana Spicer Central Tire Inflation System (CTIS). "This system can pay for itself by allowing you to get jobs in sandy areas that many of those without CTI or all-wheel drive would have to turn down," says Stevenson. "Also, if you are operating in sandy, low traction environments without CTI or all-wheel drive, this system could pay for itself by not having the downtime or towing costs that might be incurred by using a regular 6x4 configuration. A CTI system offers a lower weight and lower center of gravity when compared to an all-wheel-drive configuration."

Beverly adds, "The majority of our construction industry customers who are currently using our Dana Spicer Tire Pressure Control System (TPCS) tell us that the main advantage of the system is it consistently outperforms all-wheel-drive systems when operating in soft soil conditions such as sand or unimproved roads. On top of that, TPCS allows our customers to eliminate more than 1,000 lbs. of weight that is typically associated with a vehicle equipped with all-wheel drive.

"We've also received a good amount of positive feedback in terms of extended tire life, reduced maintenance and the lower purchase price of a central tire inflation system compared to all-wheel drive," says Beverly.

Vehicle stability and accessibility to the cab of a TPCS-equipped truck is much better than on a truck that has been spec'd with an all-wheel-drive system. For example, the height of a truck with all-wheel drive can be up to 14 in. higher.

Increased tire life

Controlling tire pressures is key to increasing tire life. "These systems can dramatically increase the life of a tire," says Alvarez. "Tires are meant to run at a specific pressure. Continuous tire inflation systems maintain that pressure. The tire expands and contracts as necessary due to climate changes, but the pressure is constant."

"Our systems adhere to tire manufacturers' guidelines and do not let air out as the temperature of the tires rise.," says Beverly. "TPCS will always maintain the minimum cold tire pressure settings as the temperature goes down."

Many variables increase tire life. "Customers have demonstrated that using Dana's TPCS can actually increase the life of tires, for a number of reasons," says Beverly. "In fact, the Tire and Rim Association (TRA) in conjunction with tire manufacturers recommend reduced tire inflation pressures for vehicles operating at low speeds for extended periods. So these groups are essentially endorsing our system to optimize tire life. At reduced pressures, you are also better protecting your tires from tread chunk-outs and reducing the likelihood of getting rocks stuck between your duals."

An onboard tire inflation system can also reduce downtime due to minor leaks. "A CTI system can compensate for minor leaks and allow continued operation of the vehicle," says Stevenson.

"The system will maintain the tire pressure and will provide air to a slow leak at the rate the air is being lost," Alvarez explains. "If the tire incurs a faster leak, the system will provide the air to the tire at a higher rate. Most systems have some sort of onboard warning device that will notify the driver that the inflation system has been activated and the system is providing air to a tire."

Heavy-haul benefits

Heavy-haul tractors and lowboy trailers benefit from the ability to control tire pressure. "With a heavier load, there is greater pressure on the tires," says Alvarez. "Maintaining the integrity of these tires and its parts via constant proper inflation is vital to ensuring the tires will function properly under stress. Many heavy-haul trailer manufacturers and their customers use automatic tire inflation systems."

Landoll Corp. has installed tire inflation systems on military trailers for more than 10 years. "With that technology, we can now use it at affordable prices for commercial trailers," says Jim Ladner, national sales manager. In fact, it has become one of the more popular options in the last couple of years.

"It's all about proper tire inflation," says Ladner. "Your load ratings are set at a certain PSI on your tires. If you maintain that, you have proper load capacity on the tire. If you maintain tire pressure, you minimize heat buildup, which just destroys tires. The longevity of the tire is enhanced so you get increased life out of it. There are documented studies that show tremendous payback on continuous tire inflation systems."

Decreasing tire pressure also allows heavy-haul rigs to negotiate soft soils. "Fleets running heavy-haul trucks and lowboy trailers in soft soil situations enjoy the same advantages as anyone else using our TPCS," says Beverly. "That being said, it is equally important to remember that the benefits of improved flotation resulting from reduced tire pressure apply to non-driven steer and trailer axles."