“If proper tire maintenance is not a priority, an operator is virtually guaranteeing he will reduce the tire’s life, increase the likelihood of tire-related failures like punctures or run flats, reduce the machine’s productivity and unnecessarily cost the company money,” says Chris Mercer, Michelin B2B construction segment manager. “It just doesn’t make good business sense now to pay attention to such a large operational asset. By keeping tires properly maintained, the benefits to the project’s budget and timeline will come.”

To stay on top of maintenance, Michelin provides the following tire maintenance tips:

- Conduct a visual inspection of your equipment’s tires prior to operation, look for signs of irregular wear, deep cracks, cuts or other major problems in the tread or shoulder of the tire.

- If any symptoms of tire damage are discovered during inspection, do not operate the vehicle until a trained service technician can diagnose the severity of the problem and make the proper repairs. Never allow an untrained person to attempt repairs.

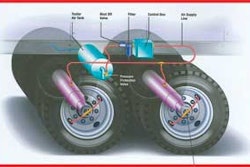

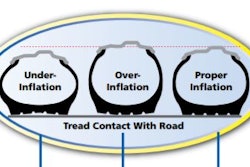

- Proper tire pressure is critical to a tire’s performance. Check tires prior to use and while they are cold for correct pressure regularly, and with a visual inspection daily. Check the pressure properly with an accurate gauge.

- Determine the precise air pressure for your tires based on the manufacturer’s requirements and vehicle application. Your tire dealer can help pinpoint the exact recommendation for your application and loads carried.

- Never operate a vehicle that has low or flat tires, damaged or distorted rims or wheels, missing bolts or cracked studs.

- Never weld or apply heat to a wheel or wheel parts. If a wheel requires repair, it should be inspected and repaired by the wheel manufacturer.

- When not in use, store tires in a cool, dry place away from direct sunlight to avoid premature aging. Prevent exposure to ozone sources such as sun, arc-welders and mercury vapor light bulbs, as well as ultraviolet rays and inclement weather. Store tires standing upright on the tread and avoid stacking.

- Avoid lifting tires through the center with a crane hook, which can damage the critical bead area. Instead, lift the tire under the tread by using flat straps. Flat straps are recommended over steel slings or chains because they are less likely to cause cuts or abrasions.

- Deflate the inners and outer tires of a dual fitment before removing any rim fixture from the hub of the vehicle.

- Avoid mixing tires on your vehicle, such as normal tread depth with deep tread depth or a bias-ply tire with a radial. Using two different types of tires could damage the vehicle’s internal components because the tires do not work together to provide the same traction and handling performance.

Fleet Manager's Guide to a Tire Management Plan - Part 1

Fleet Manager's Guide to a Tire Management Plan – Part 2

Extend Tire Life With Proper Tire Selection and Maintenance