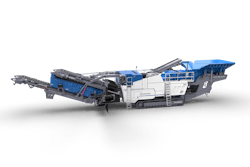

The mobile screen for coarse elements MOBISCREEN MSS 502i EVO is ideally prepared to meet changing challenges in different application areas.

The large range of screen surfaces and the simple setting of screening parameters make it possible to adapt the MSS 502i EVO easily to new application conditions.

Key features of the MSS 502i include a mobile double-deck screening unit, diesel-hydraulic drive, screen for coarse elements, and a maximum feed size of 640 x 400 x 240 mm.

Performance

A large feed hopper, screening surface of 5.4 m2 and wide main discharge conveyor provide material guidance. For flexibility during application, the speed of all conveyor belts is adjustable and a conversion from two to three final grain sizes is possible. A wide setting range of the screen casing angle (15.4 to 20°) promotes high screening capacity. Available with an optional electro-hydraulic Dual Power drive, the MOBISCREEN MSS 502(i) EVO features a large feed hopper and screening surface.Kleemann

Available with an optional electro-hydraulic Dual Power drive, the MOBISCREEN MSS 502(i) EVO features a large feed hopper and screening surface.Kleemann

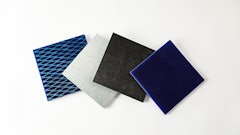

The selection of screening media also contributes to performance. Whether these are finger decks for clayey excavated earth or square mesh for classifying decorative grit – from a large selection of screen media, the screen decks of the MOBISCREEN MSS 502(i) EVO can be covered to match the required application. Mixed covering of the screen decks is also possible. Overall, the new plant offers comprehensive configurations, serving as a stand-alone machine or used with Kleemann plants.

The operating concept of the MOBISCREEN MSS 802(i) EVO is also used in the MSS 502(i) EVO. Automatic mode for production start is a core element as well as the mobile operating unit, optional radio remote control and the telematics solution for planning and analysis of the plant. A view of transfer points and material flow is possible due to LED lighting (optional Premium lighting). Access to all screen decks and maintenance-relevant components support safety.

With its compact transport dimensions and stepless drive control, the scalping screen simplifies transport from one site to the next. Equipped with joystick control, the operator has a view of the foldable belt and can move it into desired positions.

Accessibility and Application

Hydraulics on the new MOBISCREEN MSS 502(i) EVO enables power transmission during use. The machine offers access to maintenance-relevant components, flexible refueling from both sides and cleaning of the hopper discharge conveyor undersize through the use of a retractable chute.

An optional electro-hydraulic Dual Power drive allows emission-free work. Furthermore, a load-controlled fan reduces noise level and diesel consumption. Water spraying at the discharge conveyors, in turn, reduces dust emissions during plant operation.