Construction surveyors must account for many factors — seen and unseen — when preparing a site for building. From visible topography to invisible property lines, countless aspects require accurate location measurements.

Of all these, perhaps no part of site preparation is more difficult to account for than underground utility lines. Hidden under soil or concrete, these critical conveyors of electricity, natural gas, water, internet and sewage provide essential public services. An accidental strike during digging can be costly and even life-threatening, so accurately estimating their location is one of the most important tasks of surveying.

Surveyors can use different tools to locate underground utility infrastructure, but not all are adequate for high-precision applications. This article explores the importance of accurate positioning estimates in this field, delves into the options available and makes the case for real-time kinematic (RTK) positioning as the ideal choice when it matters most.

Why Precise Location of Underground Lines Is Critical

Mishaps with underground utility lines are a major problem — and much more common than many people realize. They may disrupt the flow of essential services to homes and businesses, causing interruptions in water or electricity.

According to the Common Ground Alliance (CGA), a nonprofit dedicated to preventing damage to underground utilities, accidental utility-line strikes cost the U.S. more than $30 billion per year. These accidents can cost more than money and lost time. In some cases, they lead to injuries or fatalities.

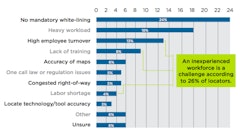

As the CGA’s 2022 DIRT Report reveals, more than 25% of those strikes were caused by locator error. For the first time, excavators and others involved in construction work were the leading source of damage reports. Altogether, these facts put more impetus than ever on surveyors getting the locations right when identifying underground utility lines.

Key Steps for Safely Locating Underground Utilities

The process for verifying and mapping utility infrastructure involves several important steps. Before any digging, construction firms must do the following:

- Call 811 — Each state has its own 811 answer line, and anyone planning to excavate is required to call to verify the presence of any utilities. Utility companies will typically send workers onsite to mark known locations with paint or red flags within a few days.

- Verify that all utilities have responded — Workers should not begin excavating until all relevant utility companies have responded and marked the location of known underground lines.

- Obtain any existing maps — If available, surveyors should also obtain any utility maps of existing lines. These might come from government archives, utility companies, private landowners or designers. Contractors shouldn’t rely solely on these maps, but they provide direction when using tools to verify the location of any marked or unmarked utilities.

- Choose the best method for verifying utility position — With a better idea of what utilities are in the area and their approximate location, surveyors can choose the appropriate verification method. They should consider whether most lines are conductive or non-conductive, how far beneath the surface they’re likely to be and how much potential interference is in the area.

Options for Locating Utility Lines

The most foolproof way to locate underground utilities is to dig — but that’s usually impractical and unsafe. That means surveyors must rely on other, non-intrusive methods to locate and map underground lines. Let’s explore a few of the most common methods.

GPR

Ground-penetrating radar (GPR) uses radar pulses of electromagnetic energy to image underground pipes. When the pulse meets an underground pipe, the energy bounces back to the surface, and the GPR antenna records the variation in the return signal.

GPR can locate conductive and non-conductive pipes beneath the surface of the ground. GPR locators cannot distinguish between different pipe materials. They only indicate whether a material is different in composition than the surrounding soil.

These signals may also experience interference from other underground materials. GPR provides real-time data, but only specially trained professionals can interpret its radar feedback. Along with the cost of equipment, this makes GPR an expensive proposition.

Electromagnetic Conductivity

Electromagnetic Conductivity relies on the electrical conductivity of underground pipes, so it will not identify non-conductive materials like clay or PVC. A transmitter generates an electromagnetic field, which will induce electrical currents in any conductive materials within its range. These currents create their own electromagnetic fields, which a receiver then picks up.

Trained technicians can analyze these secondary fields to determine the material and location of the pipe. However, the primary electromagnetic field’s strength quickly diminishes as it moves farther from the source. Readings can also be disrupted by other nearby conductive materials.

Acoustic Method

RTK increases accuracy when locating underground utilities, an essential step as construction workers prepare to break ground on any project.Point One Navigation

RTK increases accuracy when locating underground utilities, an essential step as construction workers prepare to break ground on any project.Point One Navigation

The biggest advantage of this method is its range. Sound waves are effective at up to 30 feet below the surface, much farther than electromagnetic fields or GPR. Acoustic locating works in different soil types, but its effectiveness is somewhat limited by the content of the pipes. Likewise, noisy construction environments may interfere with sound readings.

Radio Frequencies

Like electromagnetic transmitters, radio transmitters generate current in conductive pipes, creating electromagnetic fields around pipes within the soil. A receiver can detect these fields and the frequency of the return signals, providing data for technicians to locate the associated pipes.

This method, too, is only effective for locating conductive materials. It may also experience interference from nearby conductive materials and be prone to unwanted signal coupling.

RTK Technology

Any these above technologies (and some other less common ones) can be enhanced with the addition of RTK. This technology helps surveyors bring near-absolute precision to the locating process.

RTK relies on a network of fixed base stations at known locations to accurately verify receiver positioning. If a base station is close enough to the device that a surveyor is using to locate utilities, RTK technology will cancel out any known causes of error shared by the receiver and the base station, ensuring survey-grade accuracy of 2 centimeters to 4 centimeters.

When mapping the location of underground utility infrastructure, RTK removes a step from the process. Traditionally, locating underground utilities relies on two separate teams — one to find the pipes and another to map their location underground. By adding RTK to their locating equipment, surveying teams can accomplish both tasks in one seamless process.

RTK-enabled devices combine finding and mapping utility location into one seamless step.Point One Navigation

RTK-enabled devices combine finding and mapping utility location into one seamless step.Point One Navigation

One example of this type of hybrid technology is an RTK-enabled electromagnetic underground utility locator. This technology allows surveyors to locate while they map and map while they locate. By relying on GNSS signals and an RTK network provided by the technology’s manufacturer, the device can immediately translate underground readings to digital maps, directly within a mobile app.

Rely on the Most Precise Tools

When construction firms break ground on a new project, they must do so with absolute confidence that they are digging in the right place. Where underground utility infrastructure is involved, the consequences of a misplaced excavation can be disastrous.

By ensuring detailed planning with the appropriate tools for scanning the area and relying on RTK to translate scanning results into accurate underground maps, surveying teams can protect important infrastructure from damage and enhance the safety of anyone involved in the project.