Rarely, over the years, have I addressed the topic of safety. It’s not that I am ignorant of the topic, but I have focused more on leadership, sales and quality. But in this column, I would like to share some thoughts on safety and how it should relate to every pavement maintenance contractor.

Attending an OSHA class recently, I was again surprised by the nature of the incidents and accidents that take place in construction. It is amazing to me, how so many of the issues involve what I would could consider “Safety 101… the Basics,” sort of noncompliance. Let me provide a quick example or two.

One crew, working in a retail area, doing an overlay, had one of its crew members hit by a retail customer driving away from the store. Fortunately, the worker was only slightly grazed, but the incident caused much anxiousness for the driver, the employee who was hit, the crew foreman and the store manager who just happened to be outside when the incident happened. What was missing? The “grazed” worker was not wearing a safety vest.

A second example involved a sealcoating worker who, not wearing his safety glasses, received the brunt of a hose break. The break resulted in drops of the material “raining” upon the worker, with his eyes catching several drops with exact hits. When the worker was asked later why he wasn’t wearing safety glasses, his response was a simple, “It’s too hot and they keep slipping down my nose.”

Both examples are just that: examples of workers not practicing even the basics of wearing personal protective equipment, commonly called PPE. It is amazing the little things that can go wrong that PPE can prevent. Let me provide some quick reminders as to what you should be considering PPE, and the accountability for your workers to adhere to the policy.

The PPE uniform

- Safety vest. There really is no argument that supports not wearing a reflective vest. I’ve had multiple equipment operators tell me their stories of almost hitting one of their fellow crew mates but pulled away or moved a bucket the opposite direction just before possible impact.

- Safety glasses. No matter if you are spraying sealer, laying down the perfect ADA signage, or broadcasting hot asphalt across a mat to fill in little holes, the case for wearing safety glasses is too strong to argue. We want our workers to go home every day with no injury, especially no injury to their eyes, so they can continue to enjoy the beautiful sights presented when they see their spouse or kids.

- Gloves. Gloves are often the overlooked piece of PPE that can prevent silly days off because of blisters, catching splinters or burns from handling the hot pour crack filler. The technology of gloves has changed tremendously through the years, so it pays to have your workers give you their best choice of glove to wear. But get the gloves on your workers’ hands on the job!

- Long-sleeve shirt/Non-hole pants. I’ll back up a little on this piece of PPE, since some of it may smack of wearing a uniform. But, what’s wrong with wearing a uniform, especially one that has your company name and logo on the shirt? Long sleeves prevent easy nicks here and there when a worker is saw cutting, or when the milling machine is kicking up bits of asphalt. The long pants, without holes in the pants, are a must. Even my pavement maintenance business friends in Australia tell me that the days of their workers wearing short pants is ending. We just don’t want to expose skin to risky elements more than we must.

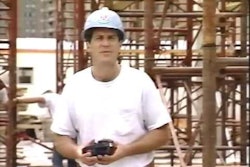

- Safety helmet. While not always needed if you are working out in the open with no overhanging work, the safety helmet can assist in cutting down on anything that might fly in the air. A skid steer using a fork to pop out stuck old asphalt can easily "chip" a small piece of asphalt into the air, just big enough to make a gash on someone’s unprotected head. The plastic safety helmet can be a real burner in the summertime, but if you’re serious about protecting your workers, you may find some ways to cool their heads while protecting them from any flying debris.

There is nothing on this list that is new for contractors. What is new is how inconsistent most contractors are toward ensuring that their workers have the appropriate, and basic, PPE. Take some time and review what you require your crews to wear. Are you sure that you are providing the best, visible proof to protect them? If you’re not, you may find it hard to recruit and retain workers who do take safety, especially their safety, seriously.

You start the commitment to safety first. You start wearing your safety vest, safety glasses, long shirts and long pants when you visit your job sites. Setting an example would go a long way toward getting easier buy-in from your workers.

Here’s to complying with the safety basics!

![[VIDEO] Personal Protective Equipment Basics - Eye and Face Protection](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2015/10/default.561e6f3d7541f.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)