In 1996, Pavement magazine published an article informing its readers about the converging chevron pavement markings being used in Japan. In 1999, Wisconsin became the first state in the U.S. to use this pavement marking pattern. It was a new pattern for the country and the state as well as an unfamiliar project for the pavement marking contractor who took on the job.

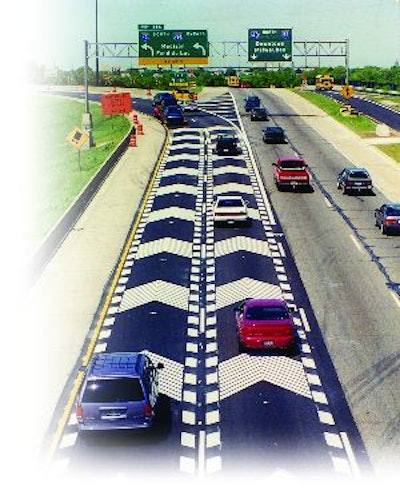

Converging chevrons are painted markings on roads used to reduce drivers? speeds and, in effect, decrease the amount of accidents that occur where the chevrons are installed. The chevron pattern consists of ?v-shaped? stripes and straight bars that gradually grow closer together. The narrowing of space between the chevrons gives the illusion that a car is going faster as the road is narrowing.

Early in 1999, the Federal Highway Administration (FHWA) gave the Wisconsin DOT approval to install a converging chevron pattern on an Interstate 94 interchange exit ramp as an experimental pilot test project. This spot was chosen because of its higher crash rate, which was above the statewide average, according to Southeast region traffic engineer with WisDOT Tom Heydel. Trucks, in particular, were having difficulty negotiating the ramp when driving in excess of the speed limit. WisDOT had previously installed overhead signs to depict the curve for drivers and included overhead speed warning signs. This had some success in reducing crashes, according to Heydel, but something else needed to be done to have a more significant impact. Heydel says that WisDOT had seen the research done on the converging chevrons in Japan and decided to ask the FHWA for permission to complete an experimental chevron pattern on I-94.

The project approval process involved WisDOT submitting a report showing the crash rate, speed of traffic, and prior methods used to reduce crashes along with other requirements. After the FHWA approved the project, WisDOT then solicited for bid quotes. Century Fence Company, Waukesha, WI, was the lowest bidder, according to Heydel, and the company was awarded the project of installing the new pavement markings.

Larry Frank of Century Fence was the project superintendent for the converging chevron I-94 job. Frank says he had never heard of the converging chevron pattern before the WisDOT project. However, Century Fence decided the new pattern was something it could and wanted to do.

Frank says they put their bid together, presented it to the state, and then the project was started. ?The unique prospect of the whole situation, being involved in a new situation, was very intriguing to me,? he says. ?It was something I very much wanted to do and be involved in.?

The project was completed over a two-night period in May of 1999. Because the painting was being done on an interstate, Frank says Century Fence had to do all the work at night. The chevrons were being painted on two lanes of I-94, and Frank estimates it took his five-person crew eight hours per lane to complete the markings.

The particular pattern installed on I-94 is 610 ft. long from the first chevron set to the last and is made up of 16 sets of chevrons as well as a line of parallelograms on both sides of each lane. Heydel says the WisDOT coordinated the installation of the markings while Century Fence did the actual installation of the chevron striping. Frank adds the state was in charge of positioning the chevrons because of the precise increments, but Century Fence was in charge of positioning the parallelograms as well as striping the entire pattern.

?Everything was measured and very precise right down to the quarter inch,? Frank says. ?This was no small task.? A large template had to be used for the chevrons. Frank says the template was so big it took four people just to lift it.

When it came to the actual striping, Century Fence used company built striping trucks. Century Fence manufactures most of its own equipment, Frank adds. Two pieces of equipment were used to complete the chevron and parallelogram pattern: one long liner truck was used for the long lines, and one hand unit (stencil truck) was used for easier maneuvering in the lane.

For those concerned with the math, two pieces of striping equipment and five workers does not add up. But Frank says no one was left standing around. ?The crew I had was doing the parallelograms and the chevrons at the same time. You had people not only moving the templates but you?re also putting beads down to give it the reflectivity. And after you go a little ways your templates are getting paint on them so you need to stop, hang up your templates in a drip pan, and physically scrape them down so you?re not getting paint all over the road. That?s why I had the number of people we had,? he says. ?Between the templates, beading, and layout, it took a number of people to do.?

Although Century Fence had never done a converging chevron pattern before, Frank says the process of striping wasn?t much different from other projects. The stencil work was similar to striping a crosswalk and the long lines weren?t much different than normal highway lines, according to Frank. The edge lines and skip lines were brought in a few inches, but the biggest difference was the size of the templates.

About four years after the original installation, Century Fence did a paint touch-up to the chevron markings. ?It was a fun job to do because it was something unique and very different,? Frank says.

Heydel says to his knowledge this is the only case of the converging chevron pattern used in Wisconsin. And he isn?t aware of any other states that have used it on a freeway or other state highway application since it is still experimental. Despite that, Heydel says WisDOT still feels the chevron pattern has been successful in reducing crashes and vehicle speeds. ?We saw a reduction on average around 5 to 7 mph. And also in the number of crashes there was approximately a 30% to 40% reduction,? Heydel says.

Franks says Century Fence doesn?t often use the converging chevron job as a marketing tool, but he says it has helped the company?s business. Since it was the first converging chevron pattern done in the U.S., Frank says the project and his company are known around the country. Plus, Century Fence has generated more, similar projects from the state of Wisconsin.

Recently, just a mile east of the converging chevron pattern, Century Fence completed the painting of a peripheral transverse pavement marking on another portion of I-94. These markings were also done as an experimental project with FHWA approval, Heydel says. Frank says he feels Century Fence was awarded this job in part because it had successfully done the chevron pattern for the state and was now familiar with this type of pavement marking.

The peripheral transverse pattern is square boxes - three squares, approximately one ft. by 18 in. each - positioned at different intervals across each lane that also gives the perception of a narrowing road, according to Frank. He says this pattern appears on more roads throughout the U.S. than the converging chevron pattern.

Similar to the 1999 project, the peripheral transverse project took Century Fence two nights to complete. However, the templates were much smaller, making the markings a lot easier to install, Frank adds. Heydel says ease of installation is one of the reasons transverse markings were used instead of chevrons. ?The transverse marking is less costly to install and easier to install,? Heydel said. ?They don?t have as high of maintenance, but yet they don?t have the same amount of impact recognition or target value either.?

Frank says he thinks the converging chevron does more than the peripheral transverse because the chevrons are more eye and attention catching. ?That?s why I?d really like to see these chevrons in a few more areas,? Frank says. The converging chevron pattern has not been approved for use yet by the FHWA, according to Heydel. But that?s not to say approval isn?t possible in the future once the FHWA can see the results of the transverse markings compared to the converging chevron markings. And if that time comes, Franks says he would definitely be willing to be the pavement marking contractor who installs them.