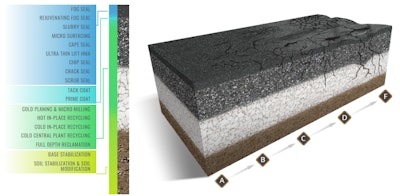

Pavement preservation is a long-term strategy that enhances pavement performance through a set of practices that extends the asphalt pavement life and improves safety. Pavement preservation treatments extend the life and serviceability of the pavement. Such nonstructural surface treatments include chip seal, slurry seal, micro-surfacing, thin overlays, fog seal and crack seal.

A good handle on the current pavement condition is critical, including information on the type and severity of existing distress.

Types of Distress on Pavement

Pavement distress can reduce performance and shorten service life of asphalt pavements. To keep the pavement at a high service level, agencies should have a pavement management system (PMS) to collect data, analyze and implement cost-effective preservation of the pavement. Also, agencies should consider particular distress types to understand the most effective treatment options.

Functional: This distress occurs when the pavement is unable to carry out its intended function without causing high stresses on vehicles. The cause of these failure conditions may be due to inadequate maintenance, excessive load weight or climate and environmental conditions. The functional distresses include fatigue cracks, block cracking, longitudinal and transverse cracking, reflection cracking.

Structural: This type of distress is an irregularity in the asphalt mix or weakness of the base and subgrade levels. The structural distresses may include shoving, rutting and depressions. In these instances, pavement preservation treatments are not an appropriate fix.

“It’s critical to understand what the distress is, because pavement preservation treatments may not be appropriate for that particular distress,” said Jim Moulthrop, former executive director at Foundation for Pavement Preservation. “Based on the condition, agencies can decide which would be the most appropriate treatment to use.”

Identify Type of Distress and Repair Options

Alligator or Fatigue Cracking:

This is a series of interconnected cracks that form a series of small blocks resembling alligator skin. This cracking may be caused by fatigue Consider full depth reclamation for this alligator or fatigue cracking as it is poor condition.Pavement Preservation & Recycling Alliance (PPRA)

Consider full depth reclamation for this alligator or fatigue cracking as it is poor condition.Pavement Preservation & Recycling Alliance (PPRA)

- Repair: This cracking should be investigated to determine the cause of failure by digging or coring the pavement to understand the structural form as well as determining whether or not subgrade moisture is a contributing factor. Repair by crack sealing is generally ineffective, instead remove all distressed area and replace the area of poor subgrade (if necessary). Replace with the proper asphalt mix, patch over the repaired subgrade.

Bleeding:

This happens when there is a film of excess primer or tack on the surface which can become sticky when drive and slippery when wet, creating loss of skid resistance.

- Repair: Repair measures may eliminate or reduce the asphalt binder film on the surface but may not correct the underlying problem that caused the bleeding. Minor bleeding can be services by applying chip surface treatment, slurry seal or thin overlay. If the pavement is too rough or signs of movement, resurfacing may be necessary, mill and overlay.

Block Cracking:

These are cracks that divide the pavement up into rectangular pieces. Larger blocks are sometimes classified as longitudinal and transverse cracking. Block cracking can be caused by the asphalt binder aging.

- Repair: Strategies depend upon the extent and severity. If there is low severity (less than ½ inch wide), crack seal to prevent the entry of moisture into the subgrade through he cracks and further raveling of the edges. If cracks are greater than a ½ inch, remove and replace with an overlay.

Raveling:

This type of failure is the wearing away of the aggregates from the asphalt causing a loss of bond between the particles and the binder. The When the aggregate starts to show, this distress is known as raveling and can be addressed with a fog or slurry seal.Pavement Preservation & Recycling Alliance (PPRA)

When the aggregate starts to show, this distress is known as raveling and can be addressed with a fog or slurry seal.Pavement Preservation & Recycling Alliance (PPRA)

- Repair: A raveling pavement should be investigated to determine the root cause of failure. Once identified, small areas of raveling can be removed and patched. If the pavement is structurally sound, a fog seal or slurry seal can be used to fix the issue.

“There is a wealth of different preservation treatments that could be accomplished,” said Moulthrop. “It is primarily dependent on what the distress is.”

Surface Treatments

Once the type of distress and cause of the distress to the pavement has been identified, next is to determine which treatment will perform efficiently.

Chip Seal:

According to the Pavement Preservation & Recycling Alliance (PPRA) treatment resource center, "a chip seal is a roadway surface treatment that consists of a layer(s) of asphalt binder with a layer(s) of embedded aggregate." This treatment provides a new skid resistant wearing surface and slows down further deterioration of the existing roadway. Issues such as minor cracking, raveling or oxidization can be addressed with a chip seal treatment. Also, it can be used to waterproof a pavement prior to an asphalt overlay.

Crack Seal:

This treatment can be a cost-effective way to treat all types of cracks greater than 1/8-inch. Issues such as block cracking, longitudinal cracking and edge cracking can decelerate the issues by applying a crack seal treatment.

Fog Seal:

This type of single application can renew weathered asphalt surfaces and improve the appearance, seal minor crack and voids which can inhibit raveling. Fog sealing can give two to four years of life extension depending on the current pavement condition.

Slurry Seal:

Slurry seal surface treatment provides skid resistance and restricting moisture infiltration by protecting the structure from further deterioration and raveling. Traffic can return to the pavement one to four hours after application and restores a uniform black appearance.

Read Next: What Surface Treatments Suits your Pavement Maintenance Needs?

Each type of treatment serves a specific purpose in the service life cycle of pavements. There are many techniques to preserve and extend the longevity of asphalt surfaces along with associations to unite network members with education, forecasting and long-term planning.

Continuing Education

These preservation treatments have been around for a long time however, technology and education about the treatments have progressed over the years. As a contractor, it is important to continually educate yourself and your crews to remain relevant in the field.

The Asphalt Institute has educational webinars/seminars and technical developments surrounding this topic, including best practices, design and application.

The Treatment Tool box designed by Pavement Preservation & Recycling Alliance (PPRA) provides an interactive, easy to use guide to help identify This interactive tool can help contractors understand the solutions for each pavement defect.Pavement Preservation & Recycling Alliance (PPRA)

This interactive tool can help contractors understand the solutions for each pavement defect.Pavement Preservation & Recycling Alliance (PPRA)

Also, tradeshows and conferences like World of Asphalt has a specific conference track directly related to pavement preservation.

By utilizing educational programs, contractors can stay competitive in today's job market and gain knowledge to not only keep up with competition, instead increase your service offering and revenue.