Pumps are a common item in many rental inventories. In a lot of cases, renting them to customers is a simple matter of determining the right type of pump and the correct size. When your customer has a large or complex project, however, it's helpful to understand a little about hydraulic science.

The start to any successful pump rental begins with asking your customer what they are trying to do, says Pete Snow, training manager at Godwin Pumps of America. "Getting a big picture view of the pumping application helps determine the follow-up questions and, ultimately, the design of the portable pumping system. Is it a small dewatering job at a construction site for a few hours or days, or is it a large sewer bypass requiring continuous pumping for weeks? The level of complexity dictates the course of action."

Bill Thompson, president of Thompson Pump & Manufacturing, notes some of the questions that the rental counter person should ask initially:

- Where is the application/pumping taking place?

- What are you pumping?

- How much needs to be pumped?

- How high does the liquid need to be pumped up/how much does the liquid need to be lifted/is the liquid in a large ditch (in other words, what is the lift pressure)?

- How long will you be pumping?

According to Snow, small dewatering jobs can be handled by gasoline-powered wet-priming pumps with suction and discharge sizes of 2 to 3 in. in diameter. These pumps can run for several hours on a tank of gas and will move up to 250 gallons per minute. "The system design usually includes 20 to 30 feet of suction hose and 100 to 200 feet of layflat discharge hose," Snow says. "General rental businesses can meet these application requirements."

On the other hand, large dewatering or sewer bypass jobs are far more complex and can involve 24-hour pumping operation and flows up to 4,000 gallons per minute and more.

Know the basics

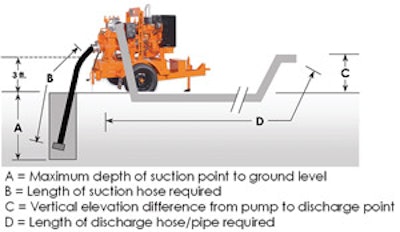

To fully serve customers with large dewatering projects, you need to first understand the fundamentals of pumping. According to Snow, the simplest way to approach a customer's pumping application is to identify three elements: flow, lift and distance.

Flow - The amount of flow (usually measured in gpm or gallons per minute) dictates the size of the pump and hose. Flow is the horizontal axis on a pump performance chart.

Lift - This means the vertical elevation difference from the water to the pump suction and from the pump discharge to the end of the hose or pipe. The more lift, or elevation difference, the stronger the pump required to overcome gravity resistance when moving water.

Distance - This refers to the space between the pump and the discharge point. This determines the amount of friction resistance encountered when water travels through the hose or pipe.

"Lift, or gravity resistance, and distance, or friction resistance, are combined to determine the total amount of resistance the pump will see during the application," Snow explains. "This is referred to as total dynamic head and is the vertical axis on a pump performance curve."

He continues, "Each pump is rated capable of achieving a certain amount of flow and overcoming a certain amount of resistance. Ideally, the pump system will be designed so that the pump operates in the middle area of flow and head, known as the 'sweet spot' of the curve."

To best serve customers with large pumping projects, Thompson notes that rental personnel need to understand that all jobs are different, they must have a working knowledge of pumps, the different types of pumps and which is best for certain applications. They also need to know about various accessories and how to properly set the pump up on the jobsite.

Hydraulics 101

While a bit academic, some of the principles governing the behavior of water are interesting and can help in the understanding of what a pump is capable of.

To start with, atmospheric pressure on Earth at sea level is 14.7 psi (one bar, or one barometric unit). The pressure becomes lower as altitude increases and higher in areas lower than sea level. With (distilled) water weighing 8.33 pounds per gallon, atmospheric pressure will force that water to rise 33.9 feet in a cylinder at sea level if all the air in the cylinder is evacuated. Likewise, mercury (Hg) weighs 112 pounds per gallon and atmospheric pressure will force it to rise to 29.9 inches in a cylinder at sea level if all the air is removed. So, what does all this mean? Pumps often have an Hg rating and what this means, for example, is 1" Hg equals the ability to move 1.13 feet of water (basic rule of thumb is 1" = 1'). Therefore, a 20-inch Hg rating means the pump will lift approximately 20 feet of water.

Thompson says pumps are designed to do two things: move the liquid in and move it out. This is achieved through creating a difference in pressure between the suction and discharge sides of the pump. The pump must create low pressure on the suction side of the system. The combination of low pressure in the pump and atmospheric pressure results in positive suction head.

Likewise, the pump must create high pressure on the discharge side of the system. This results in water being thrown out of the pump in the case of variable displacement models, or being pushed out, as in the case of positive displacement pumps. Variable displacement means that at a given speed, the volume displaced varies with pressure. Positive displacement means that at a given speed, an equal volume is displaced per cycle, regardless of pressure.

Bottom line

According to John Michael Paz, president of Godwin Pumps of America, which operates 24 company-owned stores around the country and supplies pumps to rental businesses throughout North America, renting pumps is more than handing over a piece of machinery when the customer needs it. In a lot of cases, the customer's job is complicated and involves people's lives or livelihoods. In cases like this, your business is supplying a solution to a problem as well as the machine to move water. Having a knowledge and understanding of basic hydraulics and pump technology is helpful in making that happen.

Pump terminology Static Head: The vertical height difference from surface of water source to centerline of impeller is termed as static suction head or suction lift. ("Suction lift" can also mean total suction head.) The vertical height difference from centerline of impeller to discharge point is termed as discharge static head. The vertical height difference from surface of water source to discharge point is termed as total static head. Total Head/Total Dynamic Head: Total height difference (total static head) plus friction losses & "demand" pressure from nozzles, etc. (i.e., Total Suction Head plus Total Discharge Head = Total Dynamic Head). NPSH: Net Positive Suction Head is related to how much suction lift a pump can achieve by creating a partial vacuum. Atmospheric pressure then pushes liquid into the pump. This is a method of calculating if the pump will work or not. Friction Loss: The amount of pressure/head required to "force" liquid through pipe and fittings. Flow: A measure of the liquid volume capacity of a pump. Given in gallons per hour (GPH), gallons per minute (GPM), liters per minute (L/min), or milliliters per minute (mL/min). Pressure: The force exerted on the walls of a tank, pipe, etc., by a liquid. Normally measured in pounds per square inch (psi). Prime: Charge of liquid required to begin pumping action when liquid source is lower than pump. Held in pump by a foot valve on the intake line or by a valve or chamber within the pump. Self-Priming: A type of pump that requires the casing to be filled with water before starting. Dry-Priming: A type of pump that does not need water to start. This pump can operate "dry." Information provided by Thompson Pump & Manufacturing. |