If you're in the construction industry, there are many tools and pieces of equipment that you use on a daily basis. However, few of them are as important as choosing the right pump. From centrifugal pumps to diaphragm pumps, there are many types and sizes available, which can make it difficult to choose the right one for your needs.

There are many factors to consider when choosing a pump. These factors include what you're pumping, how thick it is, the cost, the flow rate, and much more. Unless you go through every factor and narrow down your options, you're likely to end up with the wrong pump for your needs.

If you need a pump but are struggling to choose the right one, you've come to the right place. This article will walk you through the list of factors and variables to consider when making your selection and the different types of pumps available.

Different Types of Pumps

There are many different types of pumps to choose from, but there are four main ones applicable to the construction industry.

Centrifugal Pumps

If you're looking for a general, all-purpose pump that can handle a wide range of fluids, centrifugal pumps are the way to go. These are the most common types of pumps across all industries thanks to how efficient, reliable, durable, and easy to use they are. Centrifugal pumps are also very quiet and compact and require very little ongoing maintenance.

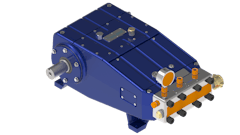

Positive Displacement Pumps

Positive displacement pumps are another popular option for filtration needs in construction. Positive displacement pumps can move a wide range of liquids and fluids, including thicker or more viscous ones. This makes them a good option in situations where you aren't pumping smooth liquids, like water, or may have some debris mixed into the liquid. Positive displacement pumps can also maintain a constant flow rate and come in a compact size if necessary.

Diaphragm Pumps

A diaphragm pump is a type of positive displacement pump, and one of the most common types available. Unlike other positive displacement pumps, diaphragm pumps move liquids by creating a vacuum that's produced by an internal diaphragm and mechanical actuator.

This simple yet powerful design makes diaphragm pumps ideal for pumping chemicals and potentially hazardous or harmful liquids. Diaphragm pumps are also very low maintenance and self-priming, further adding to their appeal.

Single and Double Head Pumps

The last two types of pumps we'll discuss are single-head and double-head industrial pumps, also known as single- and double-suction pumps. Both types of pumps are centrifugal pumps in that they use centrifugal force to operate. They have a relatively high flow rate, are low maintenance, and have a low cavitation rate. Either one is a great pump option, but double-suction pumps are the more powerful and efficient option.

While there are many other types of filtration pumps on the market, these are five of the most common.

12 Things to Consider When Choosing Your Pump

Now that you know your pump options, let's look at how to choose the right one.

1. Know Your Application

Knowing why you need a pump is the most important factor involved with choosing the right one. Some pumps are better suited for mixed liquids and solids or hazardous materials, while others are ideal for water and other smooth liquids.

2. Fluid Being Pumped

Knowing what you plan to pump goes hand in hand with understanding the pump application. For instance, the best pump for moving or circulating water is different than the best pump for filtering gas or oil.

3. Pump Flow Rate

Pumps have different flow rates, which is the speed at which they can move liquids. Some pumps are also better at maintaining a constant and consistent flow rate than others, which is another factor to consider.

4. Pressure Requirements

Along with various flow rates, pumps will also have different discharge pressures. Be sure to choose a pump that has the right amount of discharge pressure, as choosing one with pressures too high or low could slow your progress or lead to workplace accidents.

5. Temperature

It's also important to know whether you're going to pump hot or cold liquids. Some pumps are designed with internal components that can handle super-cold or extremely hot liquids, while others are better suited for moderate temperatures.

6. Corrosiveness

Whether or not you're pumping corrosive liquids is one of the most important factors to consider during pump selection. Certain pumps, such as diaphragm pumps, are better suited for hazardous or corrosive materials than other types of pumps, thanks to their inner coating and components.

7. Portability

Are you planning to move your pump from one construction site to another? If so, be sure to choose one that's compact and easy to move while still being large enough to get the job done.

8. Budget

As with all things, your budget will play a significant role in pump selection. There are dozens of different types of pumps, and they come in a wide price range, so it's important to do your research and choose one within your budget.

9. Noise and Vibration

If you plan to use your pump in residential areas, it's important to choose one that's quiet and causes relatively little vibration. Otherwise, you're likely to irritate anyone living or working close by.

10. Ongoing Maintenance

If you're looking for a pump for construction purposes, there's a good chance that you're busy and don't have time to deal with mechanical breakdowns and maintenance issues. Therefore, it's a good idea to choose a pump that's self-priming, durable, and requires little maintenance.

11. Viscosity and Solids Handling

Along with corrosiveness and temperature, it's important to know whether or not a pump can handle viscous fluids and solids. You don't want to choose the wrong pump for your filtration needs. Using a pump designed to handle smooth liquids to pump viscous ones will result in jams, clogs, and other issues.

12. Manufacturer Reputation and Warranty

Lastly, it's important to think about the brand of your pump, where you're purchasing it, and how long it will be under warranty. Not all pumps are created equal, nor are pump retailers. Therefore, even if you choose the right type of pump, you might run into issues if you choose a lesser brand or buy it from a manufacturer with a less-than-stellar reputation.