MEWP operator training is a critical component of safe and productive MEWP operations, but it is far from the only component MEWP users/employers must address to accomplish this result.

MEWP users must supplement the requirements of industry safe-use standards by good job management, safety control, and the application of sound principles of safety, training, inspection, maintenance, repair, application, and operation, which are all consistent with data available regarding the parameters of intended use and expected environment.

Since the user has direct control over the application and operation of MEWPs, conforming with good safety practices in this area is the responsibility of the user and any MEWP supervisor, operator, and involved personnel. A MEWP-specific safe-use program is a user’s best assurance that all of their responsibilities are met.

The new U.S. ANSI A92.22 and Canadian CSA B354.7 safe-use standards call for MEWP users to develop a MEWP-specific safe-use program. The program will be a comprehensive safety plan that address all of the responsibilities of MEWP users and their personnel including MEWP supervisors, operators, occupants, and maintenance and service personnel. The following is a list of responsibilities that must be included in such a plan:

- Performing a risk assessment

- Developing a MEWP rescue plan

- Selection of a suitable MEWP and work equipment associated required task

- Access, preparation, and maintenance of the site, to include assessment that the support surface is adequate to support the weight of the MEWP

- MEWP maintenance including inspection(s) and repairs

- Only trained and authorized personnel are allowed to operate and/or occupy the MEWP

- Provide model-specific familiarization to operators

- Inform the operator of local site requirements and warn and provide the means to protect against identified hazards in the areas where the MEWP will be operated

- Have trained and qualified supervisor(s) to monitor the performance of the work of the operator to ensure compliance with provisions of this standard

- Prevention of unauthorized use of the MEWP

- Ensure the safety of persons not involved in the operation of the MEWP

- Complete all documentation required

If you are an employer of a MEWP operator (i.e., a MEWP user), are all of the above tasks adequately addressed when your personnel are involved in a MEWP operation? Further consider that anytime a MEWP is operated by your employees for any purpose – loading, unloading, moving it on site, during training, maintenance, and service (literally anytime an employee moves a MEWP) – are all these tasks applied and followed?

You may wonder if your company safety policy will adequately address this need. The answer is partially, but unlikely that a generic plan will address the unique and specific requirements for MEWPs. One example is that while MEWPs are manufactured with a guard-railed work platform, occupants of boom-type MEWPs are also required to use appropriate personal fall protection equipment (PFPE). Vertical, scissor-lift-type MEWPs do not specifically require PFPE to be worn. There are many unique requirements to address in a MEWP-specific safe-use plan that a general safety plan will not cover.

Proper Training, Risk Assessments are Crucial

Performing a site risk assessment can be universally applied to all tasks. The key element of a MEWP risk assessment is the knowledge required to adequately select the right MEWP for the task and work site conditions, and awareness of the hazards associated with their use with due consideration that these machines are carrying people at height. MEWPs are available in sizes that can fit into an elevator or machines than cannot be delivered without an overwide load permit. Therefore, a qualified person is required to adequately perform a MEWP risk assessment.

Having selected a well-designed and properly serviced MEWP is also not the only factor to ensure safe MEWP operations. Having qualified persons authorized in their operation is equally important. A MEWP operator must be adequately trained as defined in industry standards to include both classroom (or online) theory knowledge and hands-on practical knowledge.

After being trained, operators must receive model-specific familiarization on the MEWP controls and operating characteristics of the machine they will be using. Even if trained and familiarized, the MEWP operator must be assessed to determine if they are qualified for the task. The MEWP supervisor must consider the experience, complexity and level of risk of the task and site conditions, and other potential factors when assessing the MEWP operator’s qualifications.

The MEWP operator has limitation as to their knowledge and experience, which means an employer requires a MEWP supervisor – the individual assigned to monitor operator performance and supervise their work in order to ensure safe MEWP operation takes place on their work sites. The supervisor must be trained to be knowledgeable regarding the rules, regulations, and standards that apply to MEWPs, the potential hazards associated with use of MEWPs and the means to protect against identified hazards, and the necessity for the operator to be aware of the requirements in the manufacturer's operation manuals.

Worksites often validate the unwritten law that “anything that can go wrong, will.” MEWP supervisors must be qualified to manage any issues that arise, starting with prevention. A MEWP-specific safe-use plan is the road map for personnel safe-work procedures, including any contingencies required, in carrying out the identified tasks. While accident prevention is in the plan, you must be equally prepared to implement rescue at height.

Site-Specific Requirements and More

Site-specific requirements are a good example of requirement that must be considered in a safe-use program. Often a site will have requirements that go beyond known regulations and standards or include specialized requirements that ‘outsiders’ would not be aware of. While the use of PFPE is only required in boom-type lifts in the U.S., there will be sites that require their use on all MEWPs in operation. While many MEWPs are drivable, driving on or alongside a public road even for short distances poses hazards that must be planned for, even if this will only be during loading and unloading.

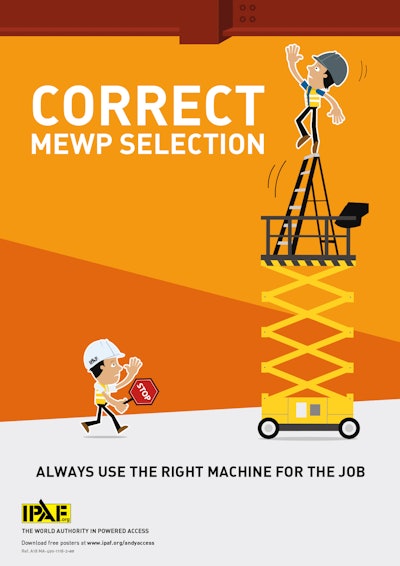

Correct MEWP Selection Andy Access Poster

Correct MEWP Selection Andy Access Poster

MEWP users vary greatly from the one-time user to the daily user of the equipment and everything in between. Where the MEWPs are used, the task being performed, the actual MEWPs in operation, the site conditions, and so on will all vary significantly from one operation to the next. The one thing in common is the need for the MEWP user (the employer of the MEWP operator) to have a safe-use program in place to address the scope and needs to ensure the MEWP operation is safe for the workers and those exposed to the operation.

To assist MEWP users being aware of and fulfilling their responsibilities, IPAF has developed a guide to assist in the development of a MEWP-specific safe-use program for their company. Be assured that it is all too easy to miss or forget something that may be critical to good planning. The guide provides a simple but comprehensive list of actions to consider when developing your plan.

To further assist MEWP users developing their safe-use program, a sample program is also available to cut and paste when creating your company plan. While it may have too much detail or too many steps for some users, it offers details that may be critical for your operations that can easily be adapted to your needs.

To view IPAF’s MEWP Safe-Use program webinar from earlier this year, visit www.ipaf.org/en-gb/resource-library/ipaf-webinar-how-create-mewp-safe-use-plan.

![Tony Groat Edited 5b57430ec070e[1] Headshot](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2024/06/Tony_Groat_edited.5b57430ec070e_1_.667c30792412c.png?auto=format%2Ccompress&crop=faces&fit=crop&h=48&q=70&w=48)