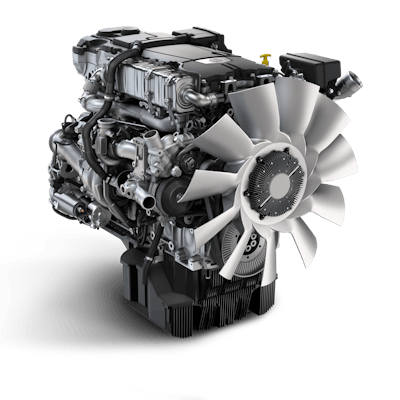

Daimler Trucks North America (DTNA) announced the start of vehicle production on February 5, 2018 with the new Detroit DD8 engine. The engine is the latest addition to Detroit’s expansive powertrain portfolio. The DD8 engine complements the already-in-production DD5 engine for medium-duty and vocational markets. It will be manufactured at the same facility as the Detroit DD13, Detroit DD15 and Detroit DD16 engines, as well as the Detroit DT12 automated manual transmission and Detroit axles.

“The DD8 is built for performance with features that meet the needs of those specialized segments,” said Brian Daniels, manager, Detroit Powertrain and Component Product Marketing. “Additionally, a big differentiator for the Detroit brand is the Detroit Connect Virtual Technician remote diagnostics system which is available as standard on both the DD5 and DD8 engines. Virtual Technician helps fleets make informed service decisions within minutes of an engine or aftertreatment fault event, increasing uptime.”

The DD8’s maintenance intervals are up to three times longer than the competition. One of the features designed with the vocational market in mind is variable exhaust cam phasing, used at low engine speeds to increase exhaust temperatures and increase uptime by reducing the need for manual regenerations. The DD8 also has a B10 life of 400,000 miles, backing the company’s commitment to delivering a robust and reliable product to this market.

Available for Freightliner M2 106, 108SD and 114SD truck models, the DD8 engine is ideal for segments such as pick-up and delivery, utility, construction, dump, mixer, plow, towing and recovery, refuse, and fire and emergency.