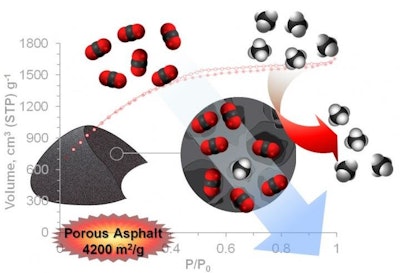

Rice University scientists have improved their asphalt-derived porous carbon's ability to capture carbon dioxide, a greenhouse gas, from natural gas.

Raw natural gas typically contains between 2% and 10% carbon dioxide and other impurities, which must be removed before the gas can be sold. The cleanup process is complicated and expensive and most often involves flowing the gas through fluids called amines that can soak up and remove about 15% of their own weight in carbon dioxide. The amine process also requires a great deal of energy to recycle the fluids for further use.

“It’s a big energy sink,” says Rice University chemist James Tour, whose lab developed a technique last year to turn asphalt into a tough, sponge-like substance that could be used in place of amines to remove carbon dioxide from natural gas as it was pumped from ocean wellheads.

Initial field tests in 2015 found that pressure at the wellhead made it possible for that asphalt material to adsorb, or soak up, 114% of its weight in carbon at ambient temperatures.

Tour said the new, improved asphalt sorbent is made in two steps from a less expensive form of asphalt, which makes it more practical for industry.

“This shows we can take the least expensive form of asphalt and make it into this very high surface area material to capture carbon dioxide,” Tour says. “Before, we could only use a very expensive form of asphalt that was not readily available."

How It's Made

The lab heated a common type asphalt known as Gilsonite at ambient pressure to eliminate unneeded organic molecules, and then heated it again in the presence of potassium hydroxide for about 20 minutes to synthesize oxygen-enhanced porous carbon with a surface area of 4,200 square meters per gram, much higher than that of the previous material.

The Rice lab's initial asphalt-based porous carbon collected carbon dioxide from gas streams under pressure at the wellhead and released it when the pressure was released. The carbon dioxide could then be repurposed or pumped back underground while the porous carbon could be reused immediately.

In the latest tests with its new material, Tours group showed its new sorbent could remove carbon dioxide at 54 bar pressure. One bar is roughly equal to atmospheric pressure at sea level, and the 54 bar measure in the latest experiments is characteristic of the pressure levels typically found at natural gas wellheads, Tour said.

Smog Eating Concrete

Another study being conducted in the Netherlands is being said to cut pollution by up to 45%.

Researchers working for the Eindhoven University of Technology spent years studying smog-eating pavement used on a city block in Hengelo, Netherlands.

According to the paper titled “Full scale demonstration of air-purifying pavement,” the block with the special pavement reduced nitrogen oxide air pollution up to 45% in some ideal weather conditions, resulting in an average reduction of 19% over a day.

The “photocatalytic” pavement used in Hengelo had been sprayed with titanium oxide (TiO2), a chemical that can take air pollutants, such as nitrogen oxide, and convert them into less-dangerous chemicals, such as nitrates, the paper’s authors report.

In a 2010 interview concerning the Hengelo experiment, professor Jos Brouwers of the Department of Architecture, Building and Planning at Eindhoven told CNN the pavement’s real-life applications were exciting.

“[The concrete] could be a very feasible solution for inner city areas where they have a problem with air pollution,” Brouwers said.

This could be good news for urban areas with high automobile traffic such as Los Angeles, where a poll conducted by the Los Angeles Times reported that close to 70% of respondents felt similar streets could be coming to Southern California.

![[Video] Volvo Prototype HX1 Autonomous, Battery-electric Load Carrier](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/10/default.5804d7fa212b9.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)