Despite the advances of computers, ipads, iphones, and other electronic equipment used everyday by the people who run plants and facilities, little has been done to innovate on the human experience and the software that supports material planning and scheduling in the asphalt industry.

A software that is easy to implement and use is especially necessary in the industry at the moment, where resources for extensive training are inexistent. A small company out of the United States and Germany - PlantDemand - is working on solving these challenges.

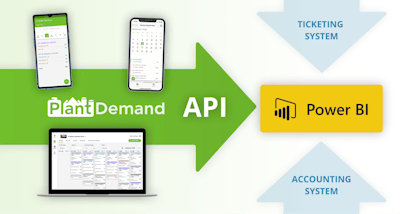

The company has released a new feature with API integration which will allow users to integrate documentation and create custom dashboards with the company data. While there are many options when it comes to integration, a simple approach is to give people the ability to query their data, and let them configure it in a way that works best for their goal. Custom reports with a data visualization tool can be created through a workflow using Microsoft Power BI and other tools.

As one report from FMI points out, “companies are looking to gain a competitive edge by leveraging technology for both revenue gains and efficiencies.” The same report says that 56% of the organizations are looking at some sort of technology strategy, but are lacking specialists to understand how to buy, implement and manage the needed softwares. As the MIT Sloan Management Review said, companies that successfully enter digitization “pull industries in new digital directions while gaining a huge head start in reaping the benefits from the new models they are creating. This forces incumbents into a race to catch up.”

Companies need such tools - where technology helps them in automating processes to improve their everyday tasks in forecasting, scheduling and planning - instead of using multiple Excel sheets and unnecessary meetings and calls. While spreadsheets and appointment calendars have their place, they are not the right tool for planning, scheduling and improving the operational aspects of the manufacturing business. They require more input than the desired output. A dedicated tool should be available to help plant operators, sales people, managers and everyone who works at asphalt, concrete, aggregate and construction materials producers.

Nowadays, most businesses keeping up with digitization are using expert agencies in User Interface, which help foster software to make technology easy and useful to their specific needs. PlantDemand conducted User Interface tests and interviews and was iteratively built, tested and optimized for construction material planning. Because of this, it is easy and efficient to enter, edit and move orders and takes a fraction of the time it would take in an ERP or in the previous solutions to plant scheduling.

Daniel Mekis, who has more than 12 years of experience in the asphalt industry materials operations, was an early adopter, and helped partner with PlantDemand says, “for the first time, people could check what was on the schedule for the next days, know what aggregates and oils they needed to bring in, or who to contact on the job, all while viewing their smartphone and sitting on the couch in the evening. For the first time, our sales manager could pull to the side of the road, view the plants’ calendar and schedule (or move) a customer’s order on his iPad, while on the phone with the customer. Plant operators and supervisors had the important information at their fingertips. And for the first time, I could give my suppliers a detailed forecast with the click of a button.”

Organizations are working hard to reduce manual methods of completing repetitive tasks and are turning to technology to help. This will give time for the team to work on more important issues. Powerful, quick and simple tools which address these specific problems are perfect to add momentum to this journey.

There are changes happening. Innovations are being implemented. The “right tool” for the “right job” is being created by someone for something. Companies are working to stay competitive. It is time to start and continue to ask yourself where your operations sit, what constraints you’re facing and how you can leverage simple, specific tools to solve the problems.