As the demand for development continues to grow, construction companies must find ways to keep up efficiently without sacrificing the quality of projects.

Today, using technology is the No. 1 element of construction that increases accuracy and takes projects to new heights. With technology constantly advancing and there being a variety of options to optimize the construction approach available today, construction firms can evolve by producing higher-quality results in less time.

This is further proven by the Construction Industry Institute, as research validates that the adoption of proven technology can improve construction industry productivity by 30%-45%, as well as improve material predictability and reliability.

Some of the industry’s top technological differentiators include:

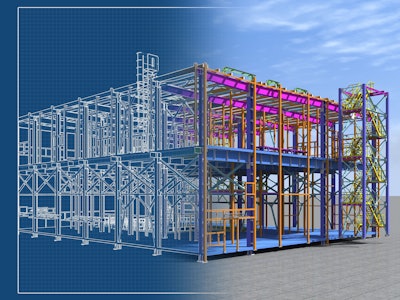

- Building Information Modeling: All our projects are modeled in Revit before a shovel goes into the ground. Our BIM/VDC department coordinates with the owner, design team, project team and all applicable trade partners to produce a unified construction model. With the recent rollout of Procore’s Coordination Issue tool within the Procore platform, our company can assign and track clash detections from the model with greater speed and with increased transparency.

- SiteAware: A digital construction verification platform, SiteAware uses drone technology, the BIM model, contract drawings and shop drawings to do a complete comparison of actual in-place work against the design, prior to concrete pours. Within hours of the photo scans, a report is generated showing any deviation from the field to the model, making it possible to make the corrections before placing concrete.

- Robotic Total Station: The robotic total station allows remote operation to be employed during the layout process by taking the BIM model and using robotic surveying equipment to implement the plans. This technology removes human error and replaces it with robotics to ensure accuracy.

In conjunction with BIM, the use of SiteAware software allows us to take BIM models and compare them to drone videos, layering them into the model to identify and provide information as to what is in the ground in up to two hours. This allows us to identify if walls, beams or other structural elements are out of place, even by a few inches. This is a level of quality that we didn't have before in construction, significantly improving production, which has resulted in less go-back work.

The greatest benefit Current Builders has noticed from using technology is that it doesn't replace the person, but allows the person to be more efficient. Information is processed quickly, which has helped with open Application Programming Interface (API) and integration for software to flow from one to the other without duplication in a single process.

BIM has consistently been the most efficient and effective tool of all the technological advancements over the past decade. Different departments are now able to coordinate easily between design teams, partners, project stakeholders and on-site staff, providing physical drawings and files for the system to lay out.

The difference between today and 10 years ago is that the processes were siloed. It took far longer to finish all aspects of a project, because of the disconnect – paperwork would have to go through multiple hands, internally before being reviewed with external clients and architects. For example, in the past, a change order, a process repeated dozens (if not hundreds) of times for each project with multiple steps and revisions, would have to through seven to 10 hands before it got out of the door. This long and drawn-out process monopolized time and brain power, but through Procore, the process has significantly been reduced by reducing the overall number of steps, the redundant reviews, and the integration of the owner/design team into the software.

The use of BIM has allowed us to use and gatekeep data about every spec of the structure from start to finish, gathering information on everything from mechanical equipment to material costs and anything in between. It has also allowed for information collected to be used to gauge the planning schedule and assist in the on-site construction organization.

This information has allowed all parties involved in project development to merge and create one model where all data about the structure is in one place throughout each stage of the building process. The data within BIM also can use simulation to track and plan the construction process every step of the way, allowing for more efficiency and less room for mistakes.

As technology continues to advance in construction, higher-quality results in a timely manner. Based on what we have experienced with BIM and its effect on our project cycles we are confident that technological advances within the space will only get more efficient over time as the industry moves toward a more advanced way of doing construction.