Engineers and owners are concerned about deflections of vertical members that control wind movements in tall buildings, and deflections of horizontal members that control floor flatness for final finishes. These deflections are proportional to the size of the members and the stiffness of the concrete. To reduce the deflections and also size of the members, engineers are specifying a minimum concrete modulus of elasticity (MOE) to ensure adequate stiffness of the structure. We have seen modulus of elasticity specifications for tall buildings in Los Angeles, Chicago, Seattle and Toronto. When encountering such specifications, contractors need to ask questions to understand the effects of mix design and testing methods on the measured MOE. Any construction requirements for placing minimum-MOE concrete should be discussed, as well as possible in-place testing and ramifications of a low test if these specifications are not met. For the sample MOE specification shown in the box, the following questions should help contractors have a discussion with the engineer and ready mix supplier.

MOE Mix Design

The mix design for a high MOE mix is different than that for a high compressive strength mix. Forget about what you know about getting a high strength and learn about what it takes to obtain a high MOE value. Ask your ready mix suppliers if they have supplied any projects with minimum MOE specifications. Ask these basic questions:

- How much did that mix cost?

- Were local aggregates used or did the aggregates need to be shipped in? How does the mix from a high-strength mix?

- What where the MOE over design values? What is the variability of the MOE at early ages—3 to 7 days? How does that compare to MOE values at later ages—28 to 90 days?

Early age MOE values (2 to 7 days) are especially likely to be highly influenced by initial cylinder curing conditions.

- Did the supplier have any MOE tests fail? If so, what were the consequences? Was in-place testing used? And if so, what in-place tests were used?

- If the concrete did not meet the specified MOE value at a required age, how were costs associated with the non-conformance disposition handled?

- MOE Testing

Testing for MOE is much different and more sensitive than testing for compressive strength. Observe a MOE test. Ask your local testing labs if They have tested any projects with minimum MOE specifications. Remember that you don’t get to choose the testing lab, so the owner or construction manager may choose one without any MOE testing experience. Ask these basic questions:

- How much does MOE testing cost?

- How are laboratory and field-cured cylinders handled for MOE testing? What effect does cylinder making and curing have on measured MOE values? What special preparation is necessary, such as grinding the cylinder ends?

- For a given MOE mix testing, what are the average, minimum, and coefficient of variation for MOE mixes of different values? What is the variability of the MOE at early ages, 3 to 7 days? How does that compare to MOE values at later ages, 28 to 90 days?

- Did any MOE tests fail to meet the specification requirements? What were the consequences? Was in-place testing used? And if so, what were the in-place tests?

- Is it possible to reach 90% of MOE at 3 to 7 days to strip formwork for mild-reinforced slabs? Is it possible to reach 85% MOE at 3 days to strip post-tensioned slabs?

- MOE Information Not Provided

Do your homework with the ready mix supplier and test labs. Then have a sit down meeting with the engineer and construction manager. It’s necessary get a feel for what will happen if the MOE values do not meet the specifications. Ask these basic questions:

- Ask the construction manager how much time has been allotted for stripping forms in the schedule and if they are based on concrete mix-specific information on MOE values at early ages?

- Ask the engineer what in-place tests can be used to verify MOE

?. Tests on cores? Dynamic MOE (pulse velocity) versus static MOE? Can or should a correlation be done between static and dynamic MOE in the mix design stage?

- What are acceptable in-place MOE values?

- Ask the construction manager who pays for in-place MOE testing if the results show that the in-place MOE meets specification requirements?

- Ask the engineer, what remediation efforts are likely if there are low MOE values for vertical members, horizontal members, or both?

MOE Target Values

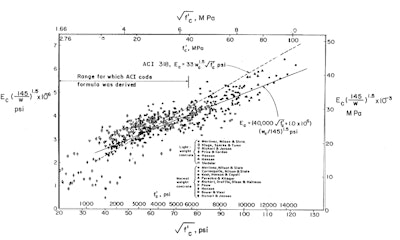

The previously mentioned MOE equations used by the specifier can be found in ACI 318 for low-strength concrete and in ACI 363 for high-strength concrete. Figure 1 shows the data used in developing equations for MOE based on compressive strength data. Note that the equations represent an average value with about 50% of the data points above and below that line. However, the specifier has the minimum MOE determined from these equations a minimum value.

ACI 318-14 Commentary on the MOE equation for low-strength concrete provides these statements:

“Studies leading to the expression for modulus of elasticity of concrete are summarized in Pauw (1960), where Ec is defined as the slope of the line drawn from a stress of zero to a compressive stress of 0.45fc′. The modulus of elasticity for concrete is sensitive to the modulus of elasticity of aggregate and mixture proportions of the concrete. Measured elastic modulus values can range from 80 to 120 percent of calculated values. ASTM C469 provides a test method for determining the modulus of elasticity for concrete in compression”.

Protect Yourself!

Make sure you do all your homework, and ask questions, and understand the cost and risk before committing to an MOE project. As the Boy Scouts say “Be Prepared!” But we like Yogi Berra’s quote better ”If you don’t know where you’re going, you’ll end up someplace else!”

Ed. Note: The ACI documents cited can be purchased at www.concrete.org.