Construction remains one of the most hazardous industries in the United States, and OSHA’s 2025 regulations are raising the bar for safety compliance. With the industry still responsible for more than one in five workplace deaths, safety can no longer be treated as a background task.

For contractors, safety managers and project leaders, keeping pace with OSHA’s evolving standards can feel daunting. But the risks of falling behind — ranging from worker injury and fines to reputational damage — make proactive planning essential. Increasingly, the difference between a successful inspection and a costly one comes down to documentation.

A Shift Toward Prevention

This year’s updates reflect a shift in OSHA’s approach from reactive enforcement to proactive prevention. Inspectors are now emphasizing real-time verification and continuous monitoring, aided by technologies like wearables, smart helmets and geofencing systems.

Falls remain the leading cause of construction fatalities, and new rules now require guardrails or tethering at lower heights — between six and ten feet. Employers in warmer regions must also implement heat illness prevention programs that include hydration, shaded rest areas and recovery cycles. Before high-risk tasks such as excavation or steel erection, crews must complete and document hazard analyses proving that risks were evaluated and mitigated.

These changes highlight OSHA’s growing expectation that safety will be integrated into daily operations, not addressed only after an incident occurs. Safety managers are now responsible not just for compliance, but for planning, training and ensuring workers have the tools and documentation to show adherence.

Expanding the Definition of Safety

For years, OSHA focused on the “Fatal Four” hazards: falls, struck-by incidents, electrocutions and caught-in or -between accidents. In 2025, the agency expanded its focus to include suicide prevention, acknowledging the industry’s mental health crisis.

More than 5,000 construction workers died by suicide in 2020, a number that far exceeds fatalities from traditional jobsite accidents. OSHA’s decision to incorporate mental health into its safety framework signals that compliance now extends beyond physical hazards. Inspectors are looking for evidence that companies are taking a holistic approach to worker well-being through awareness programs and proactive recordkeeping.

Toolbox talks, safety meetings and training logs serve as proof that employers are identifying risks and implementing prevention strategies. In a competitive labor market, companies that prioritize both physical and mental health also stand out as better places to work.

The Cost of Noncompliance

OSHA penalties have also increased in 2025. Serious violations now carry fines exceeding $16,500, while repeated or willful violations can surpass $165,000. Beyond financial penalties, companies risk shutdowns, criminal referrals or contract losses that can halt operations entirely. For firms working with thin margins, a single citation can disrupt budgets and timelines.

Compliance, therefore, isn’t just a legal requirement, but a business strategy.

Documentation as Defense

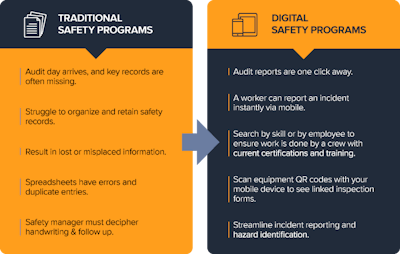

When inspectors arrive, they expect quick access to training records, hazard analyses, incident reports and enforcement logs. Companies relying on paper files often struggle to produce these records efficiently. Missing or disorganized paperwork can slow an investigation or result in penalties.

One contractor learned this firsthand when a worker fell 35 feet. During the OSHA investigation, the company’s safety manager quickly provided a complete digital record of the worker’s training and meeting attendance. The inspector commended the response, noting that such documentation often takes weeks to compile. No citation was issued, illustrating how thorough recordkeeping can protect companies in critical moments.

Compliance as Strategy

The 2025 regulatory climate leaves little room for outdated systems. OSHA expects employers to maintain organized, verifiable safety records and to demonstrate continuous improvement. Whether through digital tools or stronger internal processes, companies must make documentation a central part of their safety culture.

Compliance is no longer just about avoiding penalties — it’s about protecting workers, maintaining productivity and building a reputation for safety that strengthens every aspect of the business.