Not many companies can boast a 300 year history. Husqvarna can. Husqvarna started in 1689 manufacturing muskets for the Swedish military. The company has since evolved into a worldwide manufacturer of outdoor power equipment. In 2007, Husqvarna Construction Products entered the concrete polishing industry after acquiring King Concepts, says Dave Lepki, surface prep sales manager for Husqvarna.

King Concepts was a premier grinder/polisher manufacturer in Australia. Since the acquisitions, Husqvarna Construction products has continued to introduce innovation products and is committed to offering quality products to polishing and grinding contractors, Lepki says.

Husqvarna’s equipment

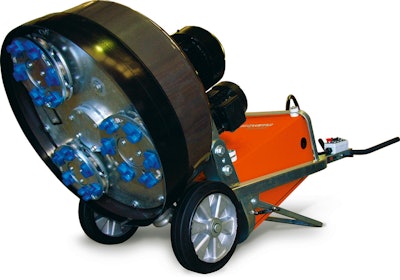

Husqvarna offers a full line of planetary grinders for the concrete polishing industry. The grinders range in size from 21 inches up to 32 inches. “These grinders incorporate our patented Dual Drive Technology that allows the planetary drum and three satellite heads to spin independently of each other,” Lepki says. “It allows them to spin in the same direction rather than just counter-rotating.

The PG820 grinder is Husqvarna’s best selling piece of equipment for the concrete polishing industry. The grinder features two motors on the planetary drum. One motor controls the planetary and the other motor controls the three satellite heads, Lepki says. “With this configuration we have the ability to control our planetary and satellite heads independently,” he adds. Like the other grinders Husqvarna offers, the PG820 can run with the satellite heads spinning in the same direction or in opposite directions.

The PG820 is powered by a 17-hp engine and is on the largest size of Husqvarna grinders with a 32-inch grinding width. It also features a five-way sealing mechanism to protect bearings and parts from slurry and concrete dust.

Lepki believes Husqvarna is unique because it manufacturers its own surface preparation equipment and diamond tools. Manufacturing its own diamond tools allows the company to perform its own research and development and keep it on the cutting edge of diamond tool technology, Lepki says.

Husqvarna also offers a full line of chemicals for concrete polishing, including grout, densifier and a guard. The GM3000 grout, for example, fills in pores, cracks and pitting in concrete and creates a smooth, clean surface finish, Lepki adds.

In addition to the equipment and products Husqvarna manufactures for the concrete polishing industry, the company also offers in-house training five times a year at its Olathe, Kan., facility. Contractors who purchase Husqvarna equipment are also given the option for on-site training as well, Lepki says.

Why join the CPAA

Husqvarna joined the Concrete Polishing Association of America as a manufacturer member in November 2009. “We feel that the CPAA is a premier organization in the concrete polishing industry,” Lepki says. Husqvarna hopes that participation in the organization will help to further promote the growth and knowledge of the concrete polishing industry.