To Baumer Hübner, "HeavyDuty" is an all-encompassing performance promise. First of all, this means that such a rotary encoder never lets its user down, even under the most difficult conditions. The HOG 10 / POG 10 incremental rotary encoder provides features only offered by Baumer that can enormously increase the fitting accuracy, as shown by the following two examples:

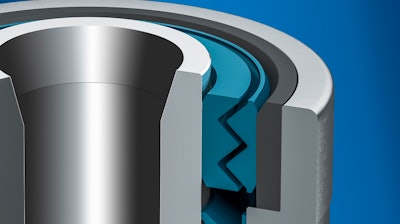

HeavyDuty rotary encoders are usually deployed in harsh environments with exposure to dust, moisture, and chemicals and therefore require powerful protective seals. But not all seals are equal. This is why HOG 10 is available with several sealing concepts for optimum protection in oily, damp, or dusty environments, for use in tropical and offshore climates, in cement works or other demanding environments.

HeavyDuty rotary encoders from Baumer Hübner excel through a robust design with bearings at both shaft ends. Thanks to unmatched resistance to axial and radial load, this double-sided bearing setup ensures maximum mechanical reserve capacity and unrivalled long service life.Baumer

HeavyDuty rotary encoders from Baumer Hübner excel through a robust design with bearings at both shaft ends. Thanks to unmatched resistance to axial and radial load, this double-sided bearing setup ensures maximum mechanical reserve capacity and unrivalled long service life.Baumer

Features and Specifications:

- Wear-free seals that endure impacts by coarse and fine-grained solids

- Sealing free from friction

- High power output up to 550 m

- Fiber optic cables ensure noise-immune signal transmission over a distance of 1.5 km

- Precise position outputs via PROFINET

- Speed signals in addition to the absolute position, for example as HTL or TTL, via serial digital interfaces such as SSI or fieldbus.

- There are various mounting options, whether as hollow shaft designs (through or non-through), cone shaft, or solid shaft with optional EURO flange B10 connection.

- HeavyDuty rotary encoders, speed switches, and tacho generators can be combined in one single robust, space-saving unit to provide varied types of output signals measured at a single drive shaft all at once.

- Large encoders such as HOG 16 / 22 /28 from Baumer are used for maximum speed limit monitoring of large drive shafts under the most difficult conditions, such as in coal dust, corrosive air, or in the burning heat of steel mills.