Corroded reinforcement is the chief cause of concrete deterioration, which prompts subsequent repairs. For repairs to be sound, contractors must ensure adequate adhesion of new patch repair materials by proper preparation of exposed reinforcing steel. ICRI’s 310.1R-2008 “Guide for Surface Preparation for Repair of Deteriorated Concrete Resulting from Reinforcing Steel Corrosion” states that exposed reinforcing steel should be free of any materials such as concrete, dirt, and corrosion products that could interfere with repair material adhesion, although a tightly bonded light rust on the rebar surface is usually not detrimental to the bond of patch materials.

Cortec Corporation

Cortec Corporation

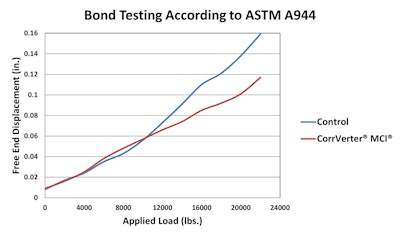

Without the need for abrasive, water blasting, and intensive labor, CorrVerter MCI, which is recommended for application to rusty or poorly prepared steel surfaces where further corrosion protection is required and good surface preparation is difficult to achieve. CorrVerter MCI is a unique formulation of chelating agents combined with a high solids waterborne latex with extremely low water vapor permeability. This fast-drying, single-component primer converts surface rust into a hydrophobic passive layer and offers excellent protection against re-rusting of metal surfaces. Reinforcement coated with CorrVerter MCI Rust Primer has similar bond strength to concrete compared with uncoated rebar.

Cortec Corporation

Cortec Corporation

Preventing Future Corrosion

One datasheet for a prominent cementitious epoxy resin stated that CorrVerter MCI reduced corrosion rate by over 40% and tripled time to corrosion, without specifying a standard test method used in the study. CorrVerter MCI Rust Primer data reported 500 hours of corrosion resistance in salt spray testing (ASTM B-117) at only 3-5 mils (75-125 µm) DFT (applied at 8.7-14.5 mils [217.5-362.5 µm] WFT). Other bonding primers reported excellent corrosion resistance in 120 hours of salt spray testing according to ASTM B-117 (application recommended at 31 mils [787.4 µm] minimum) while a third had no support data listed.

Cortec Corporation

Cortec Corporation

![Strux Macrofibers 58c9b97fd4aaf[1]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/08/strux-macrofibers58c9b97fd4aaf1.cNEEIfY9kp.png?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)