Plastic shrinkage cracks appear in the first few hours after concrete placement and typically before the finishing operations are complete. As the name implies, this form of cracking occurs when the concrete is still plastic and caused by surface shrinkage of the concrete. Occurring primarily in concrete flatwork, these cracks can also occur on other exposed, horizontal surfaces including beams, foundations, and tops of walls. Plastic shrinkage cracking is commonly associated with hot weather concreting but can occur at other times including periods of cold weather or whenever the surface concrete dries and shrinks because of rapid moisture loss.

Causes

Whenever the surface moisture of recently placed concrete evaporates faster than it can be replaced by the rising bleed water and the surface concrete shrinks more than the interior concrete, plastic shrinkage cracking can occur. Because the interior concrete restrains the shrinkage of the surface concrete, tensile stresses form on the surface. When these stresses exceed the tensile capacity of the concrete, surface cracking occurs. Cracks start on the surface and grow downward creating V-shaped cracks.

Typically, plastic shrinkage cracking occurs when bleeding ceases and the concrete is neither a liquid nor a solid. At this stage of hardening, the concrete has essentially zero tensile capacity. If concrete hardening is delayed, then the window of vulnerability and the risk for plastic shrinkage cracking increases.

Rapid moisture loss and drying of the surface have been traditionally blamed for the occurrence of plastic shrinkage cracking. However, any factor that increases the rate of moisture loss from the surface, reduces the amount of bleed water rising to the surface, or delays hardening of the concrete increases the risk of cracking.

Influencing factors include:

- Ambient jobsite conditions during concrete placement and finishing,

- Mixture proportions,

- Type and content of Portland cement and supplementary cementitious materials (fly ash, silica fume, etc.),

- Water-cementitious materials ratio, type and dosage rate of chemical admixtures, and

- Temperature of the fresh concrete.

Even construction operations including the screeding and finishing operations may influence the risk of cracking (Ref. 1).

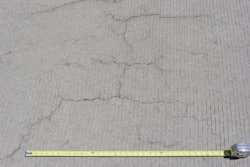

In addition to pattern cracks, plastic shrinkage cracks can also occur as isolated single cracks across flatwork. Due to drying and subsequent surface shrinkage, cracks are created by tearing of the surface when the dry shrinkage stresses exceed the tensile capacity of the plastic concrete.

In addition to pattern cracks, plastic shrinkage cracks can also occur as isolated single cracks across flatwork. Due to drying and subsequent surface shrinkage, cracks are created by tearing of the surface when the dry shrinkage stresses exceed the tensile capacity of the plastic concrete.

In fact, the risk of plastic shrinkage cracking occurring actually depends on many factors and not solely on the rate of moisture loss or rate of evaporation from the surface. However, most project specifications and ACI 305.1-06 Specifications for Hot Weather Concreting rely on limiting the rate of evaporation from the surface as the primary means of controlling plastic shrinkage cracking (Ref. 2 & Ref. 3).

The default maximum allowable rate of evaporation commonly used is 0.20 lb/ft2/hr. However, ACI 305.1 recommends reducing the maximum allowable rate of evaporation to lower values when the concrete mixture contains conventional or ultra-fine pozzolans or other cementitious materials that may reduce the rate of bleeding and delay concrete hardening. For these type of mixtures, 0.15, 0.10 and 0.05 lb/ft2/hr values are commonly specified.

Figure 1. This nomograph, based on the Menzel Formula, provides a graphical method of estimating the loss of surface moisture for various weather conditions (Ref 5).

Figure 1. This nomograph, based on the Menzel Formula, provides a graphical method of estimating the loss of surface moisture for various weather conditions (Ref 5).

Monitoring Jobsite Conditions

By using the nomograph (Figure 1), the rate of evaporation of surface moisture or more specifically the severity of the evaporative exposure can be estimated from the measured air and concrete temperatures, relative humidity of the air above the surface and the wind velocity at the surface. The nomograph is based on the Menzel Formula that was actually developed from studying the evaporation of water from Lake Hefner near Oklahoma City in the 1950s. For fascinating information about the nomograph and the Menzel Formula, see References 2, 3 and 4.

For compliance, ACI 305.1 requires the estimated rate of evaporation be calculated from the Menzel Formula instead of the nomograph. The nomograph is only a graphical guide to determine an approximate solution of the Menzel Formula. Therefore, use the Menzel Formula for compliance with ACI 305.1 specification and the nomograph for estimating the evaporation potential and the risk of plastic shrinkage cracking. Also, there are many phone apps and websites now available that use the Menzel Formula to calculate the estimated rate of evaporation.

To properly use the nomograph or the Menzel Formula, input measurements must be taken in the same manner as developed for the Menzel Formula. Specifically, measure and calculate the average horizontal wind speed at 20-inches above the concrete surface, measure the air temperature and relative humidity at a level approximately 4 to 6-feet above the concrete surface on the windward side and shielded from the sun’s rays. The concrete temperature is the temperature of the freshly placed concrete. ACI 305.1 requires monitoring to start 1-hour before the start of concrete placing operations and continue at 30- minute intervals or less until the specified curing procedure have been applied.

Instruments can be used to estimate the rate of evaporation. The user enters the concrete temperature and the instrument measures the air temperature, relative humidity, and wind velocity and uses the Menzel Formula to calculate the estimated rate of evaporation.

Instruments can be used to estimate the rate of evaporation. The user enters the concrete temperature and the instrument measures the air temperature, relative humidity, and wind velocity and uses the Menzel Formula to calculate the estimated rate of evaporation.

Editor's Note: Additions to your decorative concrete toolbox like a Kestrel weather meter, the HTC stand-up edge grinder or Bosch power tools will help you work faster and smarter. Find 9 Techie Tools for Better Decorative Concrete at ForConstructionPros.com/10830407.

Preventative Measures

Specifications typically require the contractor to take preventative measures to control the rate of moisture loss whenever the estimated rate of evaporation exceeds the maximum allowable specified rate.

Preventative measures to control surface evaporation include:

- Erecting temporary windbreaks and sunshades (if practical),

- Applying a sprayable evaporation retardant,

- Covering the flatwork with plastic sheeting between finishing passes,

- Fog spraying the flatwork,

- Dampening the base material and forms before placing concrete,

- Lowering the concrete temperature by using chilled water or chipped ice,

- Including microfibers in the concrete mixture to increase the tensile capacity of the plastic concrete,

- Protecting the concrete from evaporation during construction delays, and

- Curing as soon as possible after finishing.

Evaporation retardants are moisture-retaining films that reduce the rate of evaporation from the surface of the concrete between the various finishing operations. Because most of these products after mixing consist of one part retardant and nine parts water, they should not be used as a finishing aid or worked into the top surface of the concrete. Mixing water into the top surface can reduce concrete durability, especially abrasion and scale resistance.

Fog spraying increases the relative humidity in the air above the concrete which reduces the rate of evaporation from the surface of the concrete. Fogging can also help replace the bleed water that prematurely evaporated from the surface. However, be careful not to work accumulated surface water from fogging into the top surface of the concrete. Fog nozzles should create a blanket of fog — not a water spray that can wash away the surface of the concrete. Locate the water sprayer upwind of the concrete and discharge the spray into the air above the concrete. Pressure washers with a fine spray nozzle can be easily used to fog flatwork for small and medium-size jobs.

Plastic shrinkage cracks are usually superficial and seldom repaired. However, they may create aesthetic concerns, especially for architectural concrete. Depending on the cracking severity, crack width and depth, and the concrete’s exposure conditions, plastic shrinkage cracks may create durability concerns. For example, the potential for reinforcement corrosion and concrete damage from freezing and thawing may increase if water and deicing chemicals enter the concrete through plastic shrinkage cracks.

The best way to avoid aesthetic and durability concerns related to plastic shrinkage cracks is to understand the susceptibility of the concrete mixture to cracking, monitor the jobsite conditions, and take the necessary actions to minimize rapid moisture loss from the surface of the concrete.