Most companies that operate heavy equipment face a familiar problem: It's very difficult to collect accurate equipment hours, fuel usage and maintenance information from the field. They use time-consuming manual systems that typically yield inaccurate data.

Baldwin Paving of Marietta, GA, has found a solution. With five plants and 24 crews, it is one of the largest paving companies in the Atlanta area. Yet, it is able to accurately and efficiently track equipment operating hours, fuel usage and maintenance information by employing an automated data collection system in the field. It saves hours both in the field and in the office and ensures that equipment-related information is exact.

"We're able to track the true number of hours that each piece of heavy equipment is on the job, as well as accurately record fuel usage by each piece of equipment," said John Friedel, Baldwin Paving's chief financial officer. "We've also eliminated hours of repetitive entry of that data into our equipment-management software each week. We've become more efficient in the manner that we cost those items back to a job, and there's no delay in the information. What used to take us a month to complete now takes us less than a couple hours."

Less time and hassle

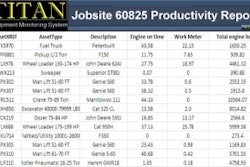

Baldwin Paving employs Spectrum Equipment Service System from Dexter + Chaney, which electronically collects asset management data for a construction company's heavy equipment. According to Dexter + Chaney, Equipment Service System eliminates the time and hassle of manual data collection and the resulting inaccurate and unreliable equipment cost and usage information.

Spectrum Equipment Service System includes three main components: Equipment Monitor, Field Master touch screen device and Fuel Controller. The Equipment Monitor, a small device attached to each piece of machinery, records a daily log of operating hours and idle hours and automatically relays that data to the Field Master. The Field Master -- which can be hand carried or mounted in a fuel truck or service vehicle -- uses a built-in cellular modem to relay equipment hours, fuel usage, maintenance and other data to Dexter + Chaney's Spectrum® Construction Software at the home office. The Fuel Controller captures gallons of fuel dispensed to each piece of equipment, which enables the company to track usage and reduce fuel theft.

Use of the system has made the job easier and more productive for field personnel like Jay Jeffers, one of Baldwin Paving's fuelers. Since the data-collection system is automated, Jeffers no longer climbs into individual pieces of equipment to read the hour meter and write down the current reading. There's also no need to keep a detailed log recording fuel for each piece of equipment. Instead, Equipment Service System electronically captures the exact hours and fuel usage.

"It saves a lot of time and it's much easier to capture hours on each piece of equipment every day," said Jeffers. "It's easy to do each time a piece of equipment is serviced in the field. With a few touches of Equipment Service System's 'Field Master,' I can automatically record hours, equipment number, amount of fuel, oil and other important information. It makes the job very easy and quick - it's something I wish we would have done a long time ago."

Tracking equipment hours at Baldwin Paving is consistent, as well as exact. "Because it's an automated system, nothing gets in the way of capturing those hours every day," Friedel noted. "Besides providing accurate hours for our costing, that also ensures that preventive maintenance is performed on time."

Dexter + Chaney has prepared a two-minute video of Spectrum Equipment Service System in action. It can be accessed at www.dexterchaney.com.