Southfield, Mich.-based architecture and engineering firm HED on April 20 announced it had become a signatory to The Carbon Leadership Forum’s MEP 2040 Challenge The leader in sustainable design is also an American Institute of Architects (AIA) 2030 Commitment reporting firm.

According to the CLF, signatories commit to:

- Establish a company plan to reduce operational and embodied carbon across MEP systems on all projects, targeting zero by 2040. Measure and report progress against that plan annually.

- Request low-GWP refrigerant availability when designing systems to reduce or eliminate GHG emissions from refrigerants.

- Request Environmental Product Declarations (EPDs) in project specifications for MEP system components

- Participate in a quarterly MEP 2040 Forum and a CLF Community discussion group to share lessons learned and contribute to a growing body of knowledge.

The 2023 Sustainability Action Plan, drafted in conjunction with the firm’s strategic plan, is a forward-facing strategic roadmap for reducing the global greenhouse gas emissions (oft shorthanded to “carbon”) of buildings designed by HED. Updated every five years, this plan was crafted by HED National Sustainable Design Leader Daniel Jaconetti, who stepped into the role in 2021 and was recently appointed to AIA national’s COTE (Committee on the Environment) Leadership Group.

“As an integrated practice, engineers have always been essential to delivering that measurable impact and their skills are crucial to the lifetime sustainability and resilience of a project,” Jaconetti said. “One of the key goals of this plan is to make every team member accountable for their role in the sustainability of their projects. We’re learning from every opportunity and going beyond setting new goals to creating accountability measures.”

David KlugHED

David KlugHED

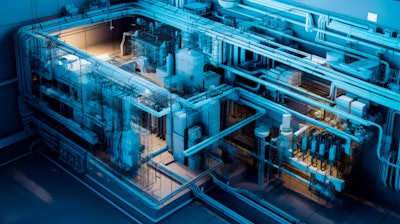

Carbon accounting in an MEP engineering process is complex and firms who are successful in this increasingly rely on simulation software manage carbon footprint of the asset under design. This process must be handled collaboratively with stakeholders including designers, contractors and owners.

ForConstructionPros caught up with HED Associate Principal and Mechanical Discipline Leader David Klug on how they use technology to work towards their stated mission as an MEP 2040 signatory.

FCP: What technology and/or performance modeling tools does HED use to quantify carbon stemming from lifecycle performance for MEP?

David Klug: When we perform life-cycle analysis for MEP systems, either to compare alternatives during design or predicting the energy use of a building, HED typically use IES. Several of our engineers are trained in IES and we have a dedicated Energy Modeling Expert that specializes in IES and modeling MEP systems. Situations arise where other tools are needed instead of, or as a supplement to, IES and we address those on a case-by-case basis. Regarding carbon, we translate predicted energy consumption of the MEP systems to Scope I & II carbon using conversion factors based on the power blend from the local utility. Our typical analysis process currently focuses on operational carbon and not embodied carbon. While there are some tools for calculating embodied carbon, such as Tally or EC3, there is not enough information provided on MEP systems yet to reliably calculate embodied carbon for MEP systems. This is one of the reasons we wanted to join the MEP 2040 challenge to push our firm, as well as the wider industry, to provide better data for MEP systems and carbon usage.

FCP: Are there any new or promising technologies the firm is seeing emerge for this purpose?

David Klug: While there’s always room for improvement, the tools currently available for calculating energy usage and operational carbon are great. In addition to IES, there are some additional early-stage modeling platforms that enable our team to complete quick analysis of potential systems and building configurations. The area that needs improvement is better information for calculating embodied carbon in MEP systems. There are some methodologies that have been published over the last few years to aid engineers in calculating embodied carbon in MEP systems such as CIBSE TM65 or the ‘LCA for Low Carbon Construction’ by The Carbon Leadership Forum. However, it starts with the manufactures and material providers to make this information more readily accessible so the current industry tools can incorporate this information and make it readily available for designers.

We have standardized the use of IES for every project since 2021. Incorporating advanced modeling into our standard workflow has the benefit of being able to analyze the impact of different system types and building configurations, regardless of client requirements. This helps us make informed decisions on every project instead of following a standard design script. Our sustainability team, which works across all disciplines including architecture and engineering, frequently holds internal training sessions to share lessons learned in building modeling and lifecycle analysis so other designers can learn and incorporate successful strategies into their own projects.

We recently competed in a design-build pursuit that included multiple buildings and a variety of space types including labs and general office. Our developer partner already had a certain HVAC system in mind prior to receiving input from the MEP engineers based on what they felt was the most efficient system. We completed early-stage energy modeling of the buildings to compare different system types and their overall energy use. We were able to use this to show there was a different system that was more efficient than what the contractor was initially planning for. The end-client for this project is sensitive to energy and carbon usage so identifying lower-energy systems was important.