One of Japan’s top general contractors, Shimizu Corp., has shifted trials of autonomously controlled construction robots into high gear.

Asia.nikkei.com reports that unit prices for construction starts in Japan have increased 20% since 2011, as the country prepares to host the 2020 Olympic Games amid a deepening labor shortage. Nikkei also reports that Japan’s four largest general contractors, Obayashi, Kajima, Taisei and Shimizu together booked 558.7 billion yen – or $4.93 billion – in 2016 operating profit, beating the sum of their initial projections by 49%. A measure of labor costs for public-works projects climbed just 10% over the same period.

There were about 3.4 million construction workers in Japan in 2014. That's expected to shrink to 2.2 million by 2025, according to Shimizu Corp.

Labor-saving efforts, such as long-term contracts for specific volumes of labor at fixed costs, account for part of the gap. Shimizu believes that the key to raising construction productivity is better working conditions, higher wages and more off-days. So the company is developing a robot-supported Shimz Smart Site with intent to not only reduce demand for labor, but to lift jobsite productivity.

Trials are run inside the Robot Laboratory at Shimizu's Institute of Technology in Etchujima Tokyo. Robots developed by Shimizu play various roles, such as transporting materials, welding steel columns or installing ceiling boards.

Shimizu expects the robots will be deployed to real high-rise building site in Osaka in fall of 2018. In the next fiscal year, the robots will work at several large construction sites in Tokyo.

The Shimz Smart Site is a production system  In the Shimz Smart Site concept, a crane holds columns in position for Robo-Welders to complete the steel framework. Robo-Carrier transports materials to where Robo-Buddy is completing floors and ceilings.Shimizu Corp.

In the Shimz Smart Site concept, a crane holds columns in position for Robo-Welders to complete the steel framework. Robo-Carrier transports materials to where Robo-Buddy is completing floors and ceilings.Shimizu Corp.

Countdown to Human-Free Construction in Less Than 10 Years

The robots undergoing autonomous control testing at the robot laboratory include:

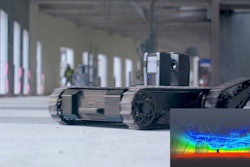

- Robo-Carrier, which conveys materials horizontally

- Robo-Welder, a robot that welds steel columns

- Robo-Buddy, a multipurpose robot that handles construction work for ceilings and floors

Each robot is a structural element of the Smart Site concept. An operator uses a tablet to send instructions that the robots carry out autonomously. Laboratory work is verifying the robots' ability to autonomously respond to various patterns of work instruction, and adjusting their programming accordingly.

The Robo-Carrier links with a temporary elevator to transport supplies entirely unmanned when the operator selects materials to convey and enters their destination in a tablet. The robot carries a one-ton pallet of plaster boards onto the elevator. On the way, the robot recognizes obstacles and reroutes on its own to avoid them. At the same time, a collision prevention feature will halt the robot if a person comes near.

To maintain awareness of its position, the Robo-Carrier uses lasers to obtain real-time spatial data which it compares with other spatial data acquired from BIM.

Caterpillar Autonomous Haul Trucks Point To Construction’s Future

The Robo-Welder has a robotic arm that uses laser shape measurement to determine the contours of a groove, or channel, on a steel column to be welded. The robot determines how to perform the job, such as the steps for cleanly placing the welding material in the channel. The robotic arm, with freedom of movement along six axes, performs the welding. The shape of the weld channels is altered to replicate inconsistencies that might occur in real work. Usually two Robo-Welders work together on one column.

The Robo-Buddy has full control over two robotic arms with freedom of movement along six axes. Sensors recognize the position of the ceiling frame grid to insert suspension bolts. One arm lifts a ceiling board to the correct position, while the other arm screws the board to the base material. At the laboratory, we are checking the Robo-Buddy's ability to install boards at a high-rise building in Osaka, as well as performance under varying construction conditions.

In the Shimz Smart Site concept, after a building’s foundation is complete, an all-weather cover is installed to shelter the construction process. A crane under the cover lowers columns and beams of the steel frame into position sequentially and Robo-Welder will weld the columns to complete the framework. Robo-Carrier and other horizontal and vertical conveyor robots transport materials from delivery to temporary staging areas at night, then disperse them to the location where Robo-Buddy completes floors and ceilings from the lower floors upward.