We saw it happen in the manufacturing sector. As robotics and automation took over certain production jobs, there were line workers displaced in favor of equipment that could do the same jobs with a high level of repeatability and reduced cost of operation.

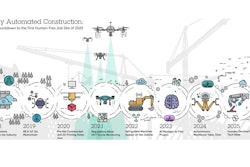

Now, as once far-reaching technology such as 3D concrete printing and bricklaying robots start to become more realistic for construction applications, blue collar construction workers are becoming nervous that their jobs may be next. Yet, new machine forms have emerged on jobsites for decades. Mechanization has been and continues to be a time-, labor- and cost-saving solution for companies facing tight project timelines, a shrinking labor pool and diminishing returns. Robotics, automation and related technologies are simply the prospective next step in an ongoing evolution.

Progress is inevitable, and the drive to enhance efficiency and profitability, mitigate jobsite hazards and solve the ongoing labor shortfall will propel the industry to seek out new alternatives. Though some jobs may be at risk, new machine forms can open doors to new opportunities for those willing and able to adopt the necessary skills. Consider the workers who were tasked with learning how to program and operate CNC machines when they were first introduced in manufacturing. By adapting to a new technology, these workers were able to maintain their roles as valued employees — and learn marketable skills in the process.

In many ways, it’s a matter of perspective. While not as familiar as a skid steer or an excavator, new machine forms are still equipment in need of operators to run them. Proper training will help to build the necessary capabilities to adapt once (or if) such equipment moves into mainstream application.

Those concerned about job security should also consider that a fair number of emerging machine types target repetitive and/or physically demanding jobs that have become very difficult for contractors to fill. Other technologies — such as remote control and autonomous vehicles and equipment — are specifically intended to enhance safety and remove workers from high-risk operations. As noted last issue, they could even enable operators to run equipment from a clean, controlled environment completely off site.

Looking beyond the machines, other types of technology are already creating new roles in construction operations. For example, the volumes of content generated by telematics, jobsite cameras, drones and other systems has driven the need for “data scientists” to help construction firms filter the information coming into their offices. New titles such as “chief data officer” and “vice president of construction technology” are becoming more common as firms seek to manage the systems and tools now available to them. Other jobs, in the office and in the field, will emerge over time as additional technology based tools come into prominence.

Construction sites and the processes used to manage and complete projects are changing. As they do, yes, certain jobs may disappear. But as history and even the present day show, other and perhaps better opportunities can develop to replace them. Those who maintain an open mind and a willingness to learn — and receive the training required — will have the best chance to adapt to this evolving work environment.