All joints serve some purpose, or no one would have bought the fasteners and taken the time to install them. Consider the cost of failure anywhere from minor property damage to major loss of life or equipment. If tightness is important, it’s equally important to know how tight, and to make sure that the torque wrench measurement is accurate.

For reasons that will be explained, there is a minimum tightness for any joint. Below this point, the joint may come apart in service either by working loose or by bolt breakage.

There is an upper value of torque beyond which the bolt can break when tightening. More likely, this upper value of torque will be reached after the bolt has been in service for a length of time. Removal torque cannot be used as a guide because it’s misleadingly different from installation torque.

Some bolts do not require as much care because of the way they are built or designed. Joints using soft fasteners, such as Grade 2 bolts, will yield before breaking. On the other hand, there are more high-strength alloy fasteners, which do not have much give before failure.

Some joints have been carefully designed to save weight, such as those used in aerospace applications or those designed specifically to save cost in mass production. Joints that have not been designed to save weight are usually stronger than they need to be, which gives the mechanic considerable latitude.

Shear joint.Wright Tool

Shear joint.Wright Tool

To understand how fasteners work, it is necessary to understand the two types of loading. Figure 1 shows a shear joint. The forces acting on the bolt are perpendicular to the bolt. These tend to cut the bolt by shear rather than stretch it.

Most structural bolts are shear. For example, the joints between horizontal beams and vertical columns are shear joints. Tightening torque is not essential to the operation of the bolt, but the tension developed from tightening may be the only thing holding the joint together. The exact amount of tightening torque required depends on the length of the bolt and other factors, but a reasonable amount of extra tightening torque does no harm.

Tension joint.Wright Tool

Tension joint.Wright Tool

Figure 2 shows tension loading, which tends to stretch the bolt. Tightening torque is important here. Automotive and aerospace joints are usually either tension or mixed joints. If tightening torque is specified, it should be followed.

It is important that the proper amount of tension is applied — not too much or too little.

A third type of loading is a combination of tension and shear. These bolts should be tightened like tension joints.

How Tight Should a Bolt Be?

The amount of tension required for a bolt depends on the size and grade of the bolt and the nature of the load.

The answer to how much tension or torque should be applied to the bolt in installation is called the “pre-tension.” The best person to answer this is the engineer that designed the joint.

Because bolt tension is difficult to measure, bolts must be tightened to a torque, but the relationship between tension and torque depends on many factors, such as lubrication, finish, accuracy of thread forms, etc. These factors add an additional source of variation.

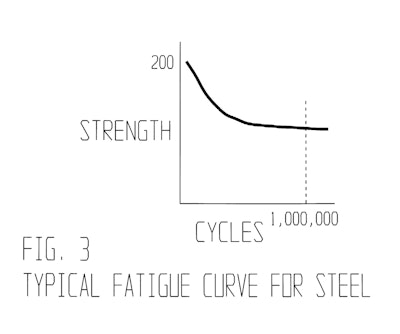

This fatigue curve chart shows the typical fatigue curve for steel.Wright Tool

This fatigue curve chart shows the typical fatigue curve for steel.Wright Tool

Steel has a property known as fatigue. (See Figure 3.) If the steel has the strength of 200,000 lbs. per sq. in. for a single load application, it will carry this load indefinitely at room temperature. If the load varies, it can eventually fail if the peak load is as low as 100,000 lbs. per sq. in.

It can take as much as a million cycles for this failure to happen. Or, it may be just a few cycles, depending upon how close the maximum is to the ultimate strength and the percentage of variation. If the steel fails from a simple case of overloading, the fastener failure will occur the first time it is loaded, or during the tightening.

If it’s a result of fatigue, the failure might occur after only a few cycles or might not occur until hundreds of thousands of cycles. One should not walk away from a bolted joint and say, “This is good, tight and nothing further can happen. It didn’t break, so it must be okay.” Even if it hasn’t broken yet, it might not be okay.

Why a Fastener Can Break from Under-Tightening

The previous section explained the dangers of bolt breakage from over-tightening. Such failure can either be immediate or delayed, or even a long-delayed failure. This might tempt someone to tighten less than what is specified to be sure that such failure does not happen.

Remember that one of the purposes of tightening a fastener is to provide enough clamp load so that the bolt or nut does not work loose because of vibration. Fasteners normally hold a joint together so there is positive clamping pressure under all conditions and fluctuations of load.

Almost all joints have flanges or other contact areas between the mating parts. Initially, these carry the same load as the bolt preload, but where the bolt is in tension, the flange is in compression.

If there is a 1,000-lb. pre-load on the bolt, there is a 1,000-lb. clamping force on the flange. If the dynamic tension load does not exceed 1,000 lbs., everything works fine.

The reason the dynamic load is much more critical and potentially damaging than the preload is that it’s applied to the structure instead of to the bolt. It is shared by the structure, and only a small part of the dynamic load is transferred to the bolt. But, if the structure is separated, the bolt must take the full amount of the fluctuation. As severe fatigue sets in, failure is likely.

Is Too Loose Better Than Too Tight?

The short answer to the above question is “no.” However, for a tension joint or a joint that is a combination of tension and shear, the answer is “neither.” In some cases, too loose can be significantly worse than too tight. If the preload is not sufficient and the joint separates under the working load, the bolt becomes more exposed to fluctuations in the applied load.

If the applied load is a cyclic load, the bolt is exposed to substantial fluctuations in tension, which may cause fatigue failure. This would not have occurred if the preload had been sufficient to keep the joint from separating. This does not mean that the bolt should be over-tightened to avoid this condition. Over-tightening can also cause failure, but it will take longer to occur.

Stronger Bolts

If bolts are replaced with stronger bolts of either the same size or larger, they must be tightened to at least the torque that was specified for the joint. This solves a simple overloading problem but will not prevent failure if the joint separates under working conditions. It’s better to increase the torque in proportion to the change in tensile strength. For an example, going from grade 2 to grade 5 will allow a 60% increase in preload. Going from grade 5 to grade 8 will allow a 25% increase in preload.

Multiple Fasteners

In an effort to make sure that bolted joints are tight but not too tight, one should not overlook the interaction between fasteners. The most common example is a bolted pipe flange with a gasket.Tightening any bolt affects the tension on all of the other bolts. The sequence of tightening will determine whether the joint leaks. It is necessary to follow the specified crisscross tightening pattern, torque steps and tightening torque.

A Happy Medium

It is clear that a fastener should be tightened to the correct load, neither over nor under. If it is a critical fastener, it should be done with an accurate, properly calibrated torque wrench.

That does not mean there is no margin for error. Designers always provide a safety margin, but that should be used as a safety, not taken up by careless or inaccurate tightening. It is also clear that if a fastener is replaced, it should always be replaced with a fastener of equal or higher grade.

Fasteners that are subject to large fluctuating loads are at risk of fatigue failure and, therefore, should not be re-used. That adds to the number of cycles. Even the act of loosening and re-tightening a fastener shortens its life if it is used in a high-fatigue application.

If bolts break after a period of service, it might be because of an increase in load or a result of fatigue. In either case, it would be desirable to either use stronger bolts with an appropriately higher torque or add more bolts to the joint. Another safety precaution is to buy fasteners only from reliable suppliers. Mislabeled or below-standard fasteners should be avoided.