When it comes to project completion, one thing stands between success and failure: a thought out, effective lift plan. Without a comprehensive plan, a project can take a turn for the worst. This in turn can lead to project down time, higher costs and, at times, project failure.

However, to alleviate these outcomes, Area Erectors, Inc. was able to successfully implement the 3D Lift Plan by A1A Software, which contributed to the project's success.

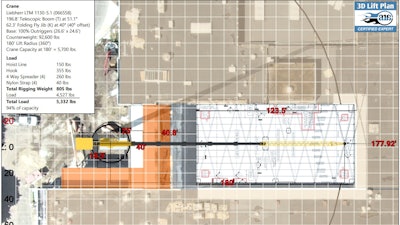

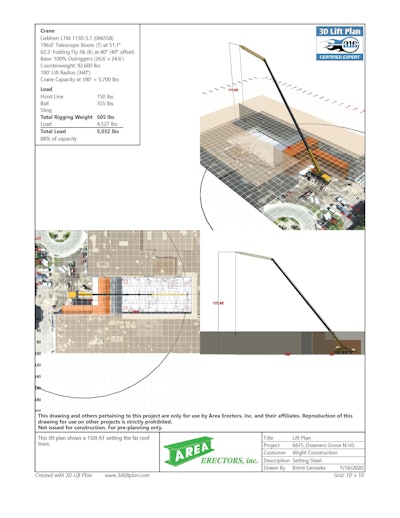

Illinois crane specialist Area Erectors, who was recognized as the third-place winner of the 2020 3D Lift Plan of the Year awards program for their role in the construction of Downers Grove North High School, was able to utilize the 3D Lift Plan for crane selection and placement, and later to review the rigging and lifting scenario. The ability to use the 3D Lift Plan was essential due to the fact that crane placement options were limited at the school in a residential neighborhood, where a shop-fabricated steel truss was to be placed in a courtyard.

“In the lift plan for this project, we set a 4,527-lb. shop-assembled truss over an existing/addition walkway, inside a courtyard, on top of new steel,” notes Brent Genseke, project manager and structural steel estimator for the project. “This was not a heavy lift by any means, but crane access, transportation of the truss to the site and rotating the truss once it was off-loaded added some degrees of difficulty to the lift.”

Visualizing a Clear Plan

Genseke explained that they regularly use the 3D Lift Plan in the planning stages to size a crane, and after the project is awarded to help lay out crane locations for different stages of the project, which helps determine whether to complete the job in-house or outsource. In addition, the 3D Lift Plan can be used to finalize the lift plan and convey key information to the field team on the project.

In this case, they coordinated crane selection with the vendor, since they didn’t have the ideal crane for the project in the fleet. 3D Lift Plan was a big help in making that determination, and had already pre-qualified Nichols Crane to provide what they needed.

Crane placement on this project was limited due to underground hazards, and they needed to ensure that the other trades could keep working without interruption during the construction process. After the initial sizing and creation of an accurate representation of the jobsite using 3D Lift Plan, Nichols Crane was called upon.

A1A Software

A1A Software

That composite image allowed the company to give the general contractor and the owner, which in this case was the school district, a clear, accurate and up-to-date idea of the lift plan submitted and the conditions at the site.

“The printouts outline the crane and rigging configuration, crane capacity, location, clearances and load information, so we were able to provide a level of detail that enabled the GC and school district to understand the plan,” Genseke says. “Being able to clearly visualize what we were planning and trust in the accuracy of the information gave them confidence that we would complete the work in a safe, efficient manner.”

Overlaying the drone imagery and the 3D model is a useful tool that includes all the possible obstructions that are on the jobsite – piles of scaffolding, lumber, fencing, staging of block or steel, or parked trucks. Knowing exactly what to expect the day work begins allows companies to factor in all those other things that have to be worked around.

Other Features Aid Planning

For this particular project, they didn’t need the laydown feature of 3D Lift Plan that shows how and where the crane will be assembled because they utilized a hydraulic crane with a jib (Liebherr LTM 1130 5.1), but on projects where they use a crawler crane with a boom that requires a lot of space, the laydown feature is great for on-site planning because it displays dimensions and shows the area required to assemble the crane.

3D Lift Plan also includes a crane selection tool with a search feature that helps instantly identify the most economical crane configuration based on the available cranes that can handle the lift so you don’t have to search manually through a long list.

Genseke finds that 3D Lift Plan’s special tools give them the ability to bring as much information as they need to the table throughout the process. “After taking some time to become familiar with using the XYZ coordinates of the rigging designer tool, we often use it in creating the rigging plan. It allows us to choose from predefined configurations or to create a custom design for rigging, and it calculates sling angles and tension, as well,” says Genseke.

A ground bearing pressure feature can be used to automatically calculate crawler loads and outrigger loads. “We use it to calculate the ground bearing pressure below our crane mats and the stress being applied to them,” says Genseke. “We also routinely use the crane mat selection tool to depict the exact crane mat that will be used under the outriggers and size it for the mats they have for a visual reference.

“We count on 3D Lift Plan to help solidify a plan that details the parts needed and to factor weight correctly,” he adds. “It gives the operator an idea of what the weight will be so they can calculate what’s going to be required.”

Genseke expects the benefits to continue to expand. “3D Lift Plan is highly user friendly and they make constant improvements that continue to expand the options and enhance intuitiveness for the user,” he states.

But perhaps the greatest value is the level of transparency Area Erectors is able to provide to clients. “Our clients commonly want to be kept apprised of every nut and bolt,” says Genseke, “and we are much more capable now of providing the high level of detail they demand with the tools that 3D Lift Plan puts in our hands.”

*Information provided by A1A Software based on a project success story shared by Brent Genseke, who served as project manager and structural steel estimator on the Downers Grove North High School. Article edited by Chantal Zimmermann.