With OEM and third-party telematics offerings increasing in number and capabilities, fleet managers in the construction industry have more leeway to find a solution that’s right for their needs. And with the amount of small equipment and power tools on a jobsite, construction tool tracking systems are just as important. Fleet management software (FMS) allows you to track both heavy construction equipment, such as cranes and diggers, as well as small construction tools, like drills and jackhammers. Additionally, you can integrate other fleet solutions into FMS to consolidate all fleet-related data onto a single platform with single sign-on (SSO) functionality for increased security and reduced login hassle.

Tracking and monitoring assets through a cloud-based FMS provides a real-time view of your tools and equipment, including assignments and location, to keep team members accountable and automate inventory counts and service workflows as needed.

Tools and small equipment should have a designated home from which they’re taken when checked out and to which they are returned at the end of the day or job.Fleetio

Tools and small equipment should have a designated home from which they’re taken when checked out and to which they are returned at the end of the day or job.Fleetio

Asset Assignments Increase Accountability

The ability to easily track fleet assets—especially regarding smaller tools and equipment and even PPE—depends a good deal on how and where you store these items. Do workers sign assets out as needed or do certain items stay assigned to specific vehicles? Tools and small equipment should have a designated home from which they’re taken when checked out and to which they are returned at the end of the day or job. Even if an item’s designated home is on a vehicle, individuals can still check out the item directly from the vehicle.

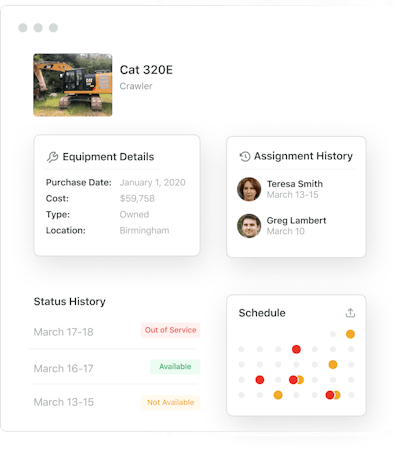

Assigning tools to individual operators is one of the easiest ways to keep track of your tools, and FMS makes checking out and assigning assets via a mobile app quick and easy. Users can view tool availability, quickly assign tools to themselves and begin their workday. Choosing FMS that syncs with a mobile app eliminates the need for expensive, cumbersome barcode scanners. Instead, operators can scan equipment tags, barcodes, QR codes or Near Field Communication (NFC) tags or stickers with their mobile device.

Managers can also assign assets instead if that is preferred. FMS allows managers to create and edit schedules for tool assignments and instantly alerts team members of the assignments via the mobile app. Leveraging software to manage construction tool assignments keeps your team in sync and allows users to easily view which tools are in-use, available or out of service.

Tool assignments also empower your team to be accountable for their tools. When a tool is lost or damaged, you can easily view who used it last and act accordingly. With tool assignments, team members are more likely to keep track of their tools and ensure they stay in good condition. This also reduces tool misplacement and allows you to coach up or train individuals on proper tool handling, storage and care.

Implementing a tool checkout system ensures your team keeps tools and equipment organized and returns tools after each use. Not only does this help you maintain an accurate inventory count, but it also informs other users when certain tools are free to use, streamlining communication and increasing productivity.

The number of tools and small equipment you manage can range widely, but one thing is certain: trying to manually track inventory often results in inaccuracies.Fleetio

The number of tools and small equipment you manage can range widely, but one thing is certain: trying to manually track inventory often results in inaccuracies.Fleetio

Loss Prevention through Inventory Accuracy

The number of tools and small equipment you manage can range widely, but one thing is certain: trying to manually track inventory often results in inaccuracies. FMS takes the guesswork out of the equation by automating inventory counts and storing tool details. You can track value, location, status and other information in FMS to ensure that even when you aren’t physically at the jobsite, you can stay informed of any tool status changes and access all asset information in an instant. You can also easily edit values and tool details to keep asset records up to date. When you acquire new tools or replace old ones, you can quickly add or remove tools from your system.

FMS makes it easy to ensure no tools go missing. Managers can compare physical counts to the numbers in their FMS to ensure all tools are accounted for and quickly identify any missing tools down to the barcode.

Watch a video about expanding the life of your equipment:

Track Usage, Performance and Maintenance Histories

While everything we’ve covered so far really focuses on accountability and physically keeping track of small equipment and tools, one of the greatest benefits of using FMS for asset tracking is the ability to gain insights into usage, performance and maintenance histories.

As tools and equipment start to see more use on jobsites, maintenance histories can show if PM schedules need to be increased or have services added.Fleetio

As tools and equipment start to see more use on jobsites, maintenance histories can show if PM schedules need to be increased or have services added.Fleetio

These are the details that inform you regarding:

- Optimal inventory count: Tools and equipment that are frequently checked out and which yield high usage hours during times they are assigned can indicate the need to acquire additional inventory. Overusing tools and equipment can drastically increase wear and tear and preventive maintenance (PM) and repair expenses. Balancing out the usage across a larger inventory can reduce service expenses and improve asset lifespans.

- Top performing brands: A great thing about FMS is its ability to consolidate and aggregate data for easy reporting. This means if you want to determine information like top performing asset brands, you can simply pull a report. Procuring assets is always an investment, so knowing which brands are best suited to specific jobs can increase your ROI.

- Improved PM schedules: Just like with vehicles, it’s important to be proactive when it comes to tool and small equipment maintenance. As these items start to see more use on jobsites, maintenance histories can show if PM schedules need to be increased or have services added.

While FMS allows you to remotely track and monitor tool assignments and location, the insights it provides into the usage and performance are just as beneficial. Optimize inventory counts to boost productivity and extend asset life cycles while improving PM schedules, and ensure you’re always getting the right tool for the job.