Which oil filter strikes the best balance between performance, cost and longevity? To find the answer, you may want to view the oil filter as a type of insurance policy.

"No contractor needs an oil filter," says Bert Elfers, director of product management, Baldwin Filters. "What they need is protection for their equipment. If it ran fine without filters, they would be satisfied. That said, they are really shopping for the best insurance to keep their equipment operating and generating money."

Filter selection tips

Do not match replacement filters only by dimensions. The internal components and specifications can be different. Some important differences include the use of anti-drain-back valves, bypass valves, post seals, varying media types and a range of burst or collapse pressure ratings.

"In general, if the OEM filter had certain features, such as a bypass valve or an anti-drain-back valve, you want to make sure you maintain those same features," says Keith Bechtum, engine liquid filtration group, Donaldson.

"The OEM has balanced the trade-offs of things like oil starvation vs. unfiltered bypass flow," says Elfers. "Choosing to ignore their recommendation is flirting with disaster. OEMs publish specifications for the filters, including efficiency and capacity. There are less notable factors, such as burst, element collapse or bubble point, pressure drop and even can thickness. The best way to ensure a replacement filter meets the OEM demands is to buy a brand that has built its reputation on meeting or exceeding OEM requirements."

The type of media used really determines filter performance and cost. "Cellulose filters are the most common because they provide the most value," says Elfers. "They have long life with moderate efficiency at an attractive cost. Synthetic media drives up the efficiency, but at the expense of contaminant holding capacity and cost."

Decisions on the best compromises must be made. "Efficiency, capacity and restriction all must be balanced in a given envelope," says Elfers. "Opting for a higher efficiency will increase restriction and shorten life unless more media surface is added. Filter capacity is based on the restriction imposed on the system. Most tests establish a 20-psi pressure drop as the point at which a filter has reached its capacity. A higher efficiency filter will have a higher initial restriction. It will plug faster because it will filter out smaller contaminants, resulting in shorter life."

But switching media changes the efficiency/flow restriction equation. "In general, the tighter efficiency filter will have a higher flow restriction and a shorter life," says Bechtum. "The way you change that game is to change the type of filter media you are working with, such as using a synthetic media. You can get better efficiency for a given pressure drop." The downside is synthetic filters typically cost roughly twice as much as a standard filter.

Despite the added cost, synthetic media is typically your best option when it comes to severe conditions or extended change intervals. It has other advantages, as well. "The engine vibrates as you are driving," says Bechtum. Oil surges are also created upon startup. These can dislodge contaminants in the filter. "A contaminant has a tendency to either pass through a cellulose media or slough off of it. It doesn't do that to the same extent with synthetics."

Some filters offer a combination of cellulose and synthetic media. This provides some, but not all, of the benefits of a synthetic at a lower cost point.

It is the capacity that determines oil filter life expectancy. "Excess capacity is wasted if filters are changed before reaching capacity," says Elfers. "On the other hand, running out of capacity before a scheduled change interval can result in the bypass valve opening and allowing unfiltered oil to the engine, or even collapsed elements with catastrophic failure."

Brent Birch, laboratory manager, Champion Laboratories, supplier of Luber-finer filters, adds, "The filter should have reserve capacity 'headroom' to run the drain intervals the engine manufacturer specifies, or drain intervals the user has oil analysis data to support."

The capacity of the OEM filter serves as a good starting point. "You always want to have at least that much because that gets you to your standard drain intervals," says Bechtum. "After that, you are looking for an extension of the capacity."

Extending drain intervals

Extended drain intervals place the greatest demands on oil filters. "Extended drain intervals require extra capacity, as well as media and pleat construction that can withstand the extra duty," says Elfers. "This usually means a higher synthetic content and measures to ensure pleat stability, such as glue beads."

But not all applications call for synthetic media. "It is not correct to categorically state only a cellulose/synthetic blend or glass-type media construction is suitable for extended drains," says Birch. "Each type of construction has pluses and minuses and filter manufacturers must balance these features."

Filters must be constructed to withstand the longer duty cycles of extended drain intervals. "There are filters that have premium materials to withstand the additional length of time in service and exposure to the elements," says Birch. "This includes elastomers, filter media, metal parts and adhesives."

On standard filters, these components often do not offer the necessary durability for extended drains. "Because it is a very cost-competitive market for standard filters, you cannot afford to put expensive parts on there," Bechtum explains. This is why Donaldson offers its Endurance line, which is specifically designed for extended drain intervals.

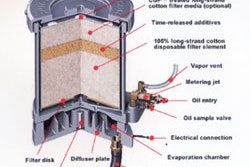

Donaldson also offers the Endurance Plus line for the on-highway market, and is looking to expand this product into the off-road market. "The engine oil will actually wear out before the filter in many applications," says Bechtum. These filters extend oil life by releasing additives to replenish depleted additives.

Installation tips

Oil filters must be tightened to the proper torque specifications. "Over-tightening can damage the can or over-compress the gasket," says Elfers. This may cause leaks and make it harder to remove the filter when needed. Always check for leaks around the filter and drain plug.

Also apply a light coat of oil to the sealing ring prior to filter installation. "Once that seal begins to make contact, you still need to turn the filter," says John Hacker, director of liquid filtration development, Donaldson.

"Applying a film of oil to the gasket reduces friction and gives you a better feel for the torque being applied," says Elfers. "It also prevents the gasket from turning and twisting in its groove."

"To put a filter on 'dry' imparts unusually high torsional loads on the elastomeric material, and greatly increases the potential for the filter to be in an under-torqued condition," Birch points out. It can then loosen and leak.

"Damage to the filter canister/shell by the installation tool is also likely when installed with a dry gasket," Birch adds. "Filters with dents and damage should be replaced immediately as the filter assembly may not resist the pressure impulse and vibration loads as designed."

Installation information is usually printed on the side of the filter can. "The side of the can will tell you how many turns once the gasket has contacted the surface," says Bechtum. This varies from engine to engine.

"Careful use of a filter wrench is acceptable to achieve the required torque/turns," adds Birch.

To pre-fill or not to pre-fill

"Pre-filling oil filters reduces the 'dry start' period required to fill the empty filter, which must occur before the lube system can achieve pressurization," says Birch. "The media is also wetted prior to being subjected to the high-velocity oil that enters a dry filter upon startup. Pre-fill is a good practice when the equipment, environment and maintenance supplies are clean."

But there are also downsides to pre-filling filters. Elfers explains, "Your first thought would be that pre-filling prevents oil starvation during engine startup, and therefore should be standard operating practice. This has limited value, however, as oil changes should be done on warm engines and these will have a fresh coating of oil on all vital parts. The momentary starvation of oil on startup is negligible compared to the potential harm that can result from introducing contaminants in the pre-filling process."

If you do choose to pre-fill the filters, make sure to take adequate precautions. "It is important to recognize that contamination removed from the engine lube system by the full-flow filter is, for the most part, smaller particles than the eye can detect," says Birch. "You cannot take too many precautions regarding the cleanliness during oil changes and engine service."

Don't just randomly pour oil into the filter. "If you do pre-fill, pour the oil in the dirty side, where all of the smaller holes are, so you are getting the oil to go through the filter," says Hacker. "That way, any contamination in the oil will have to pass through the filter. That is kind of an inconvenience for some people, but it is what we recommend."

"When filters are pre-filled through the threaded hole in the baseplate, the oil is going directly to the clean side of the filter. It will not be filtered prior to its path through the pressurized lube system," Birch points out.

"Trying to add oil only to [the outside holes] of the filter is a good intention, but difficult in practice," says Elfers. "The safer practice is not to pre-fill."