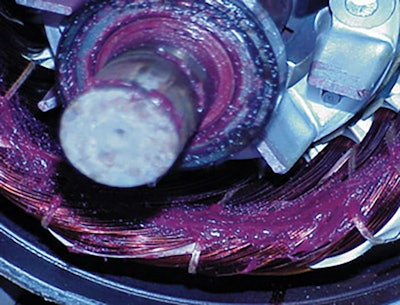

Overgreasing can lead to high operating temperatures, collapsed seals and in the case of greased electric motors, energy loss and failures. The best ways to avoid these problems are to establish a maintenance program, use calculations to determine the correct lubricant amount and frequency of relubrication, and utilize feedback instruments.

When it comes to regreasing bearings, more is not always the better option and actually can be a costly mistake. Instead, greasing should be set on a frequency with proper calculations used to determine the amount of grease needed at each relubrication. The determining factor for the amount required is based on the dimensions of the bearing or the bearing housing.

(Read the entire article, "The Dangers of Overgreasing," from Noria Corporation...)