A pump is an essential tool for quickly and efficiently removing unwanted water from a location. While on on the surface, the task it performs seems quite general, it is not a one-size-fits-all product. There are several types available, as well as varying degrees of quality. Selecting the proper pump for the task requires doing a little homework on the types available and what to look for from a quality standpoint.

A Selection of Centrifugals

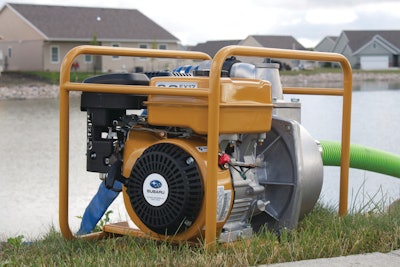

Most small dewatering pumps fall in the centrifugal category. These pumps use centrifugal force to move objects away from the center in a system of circular motions, increasing the pressure as it rotates. The force is caused by the rotation of the impeller, a circular disk with vanes that sling water around.

The impeller is enclosed within a housing known as the volute, and it collects and directs liquids through the pump. As the liquid is rotated, its velocity is increased, allowing it to be expelled from the pump very quickly through the discharge.

A standard centrifugal pump is the most basic type and handles the simplest duties. Used to move clean water containing little or no debris, it is perfect for tasks such as draining a pool or removing unwanted standing water. It is inexpensive and performs its function very well.

For water with a higher solid content, you will need a semi-trash pump. Its impeller has deeper vanes to move more debris as needed. These pumps also generally have a larger discharge opening to allow for smaller debris and particles to easily pass through.

Trash pumps are almost identical to semi-trash pumps, but have even deeper impeller vanes to allow for the largest discharge capacity. These pumps are used to move water that is muddy, sandy or contains other solids that would damage the inner workings of a standard pump. Generally, trash pumps are built with a more heavy-duty pump housing, which make them more versatile. They are often standard equipment on construction sites that need to move water, particularly when the water may contain abrasive materials.

Of all the pumps available, a diaphragm pump may be the most versatile. It is capable of handling sticks, stones, mud, trash and other large debris. Basically, anything that can fit through the opening will be able to go through without damaging the pump. It can move seawater, re-circulated water, and muddy, sandy and viscous water.

Despite its universal appeal, diaphragm pumps are the most expensive, so most users only choose it if it's the only pump that will work. In addition, they operate at a much slower rate than centrifugal units, so speed is another factor that must be taken into consideration.

Unlike its counterparts, diaphragm pumps do not have an impeller. Theys have two chambers, and work using an action similar to that of an internal combustion engine. As the volume in one of the chambers is increased, the pressure in the other decreases, drawing in fluid. This fluid is later forced out once the pressure in that chamber is increased, and the process is repeated.

Quality Counts

While determining the type of pump needed for a specific application is important, it's just as important to identify the characteristics of a well-built, quality pump.

A pump won't operate properly without an adequate engine. Look for one from a reputable manufacturer. Be sure it comes with a good warranty, and that parts are easy to find if needed. Luckily, most pump engine maintenance is preventative, and simple care usually extends the machine life as a whole. Generally, quality pump engines can be expected to last for upwards of 2,500 hours of operation, sometimes more if the recommended maintenance is followed.

Just as important are the pump housing and inner components of the pump. This is especially true on semi-trash and trash pumps, which are more likely to handle materials that can wear the pump out prematurely.

Check out are the mechanical seals and the impeller, which are generally the first two parts to break down if and when there is a problem. The mechanical seal protects the impeller from wear, and can greatly increase overall pump life. Quality centrifugal pumps generally have self-lubricating carbon ceramic mechanical seals, and semi-trash and trash pumps have self-lubricating silicone carbide seals. These are the best seals to combat the wear caused by repeated use, and also keep the pump from leaking.

A cast iron impeller is also a necessity in pumps that will frequently be transporting solids. The impeller on some models is plastic, and may not stand up well over time. In addition, when buying a trash pump, make sure the pump has a wear plate to act as a buffer between the impeller and volute. This piece prevents solids from passing through the pump.

The pump housing is available in a variety of different materials. Higher quality housing is made of stainless steel or, in the most sturdy pumps, die-cast aluminum. While this type of housing may cost slightly more at the initial purchase, the extended life it will afford the pump will more than make up for the money saved buying a housing that is plastic.

The strainer keeps oversized debris from entering the intake hose and causing damage to the pump. Again, look for a metal strainer, since plastic pieces will usually crack or break over time, and won't keep unwanted debris out of the pumps hoses, causing them to become plugged.

Just as with other pieces of construction equipment, pump quality can vary greatly from one to the next. And although pumps are typically used for one simple task – moving water from point A to point B – a quality pump is clearly a wise investment, and one that will bring dependability and a greater return over time.