In a soft launch this week, InTempo announced a slough of new features for its rental management software suite.

The two companies partnered in 2022 on InTempo MX, which merges telematics and rental management information, from GPS locations and machine utilization data to dispatch information and preventive maintenance schedules. This helps increase available rental days while reducing unscheduled maintenance events.

In a Q1 2024 roadmap video, InTempo Product Manager Tony Tye, Michael Jakab, LHP Telematics’ business development consultant and LHP Telematics Sales Representative Faith Walters provided an overview of what is new in the product, including enhancements available at the end of November 2023:

- Machine hour updates in InTempo

- Visual cues on the map for assets either due or overdue for service or pickup

- An account manager filter displaying equipment location, status and contact data, empowering company contacts to more closely follow the business

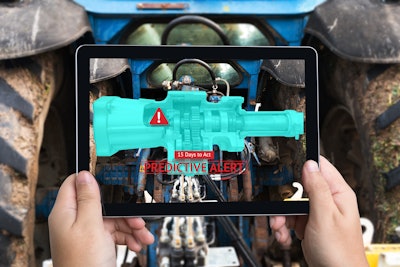

Predictive Maintenance Power

Slated for general release in Q1 of 2024 include a fleet dashboard for executive management, which is going into design in January, and monitoring tools for specialty equipment like compressors including multi-condition alerts.

“We will also be releasing a Cummins-dedicated diagnostic service, and that would be available to anyone who is a subscriber in the system,” Jakab said. “That is particularly of interest to people who want to know fault code diagnostics for Cummins equipment and remedies, as well as predictive analytics that go along with that.”

This feature will require the use of a LHP TP1 device, which can handle the robust nature of the Cummins data stream, attached to a supported Cummins engine.

In a probing feature on IRONPROS, Jakab explains how predictive maintenance is difficult to deal with in aftermarket systems –LHP had had data scientists on staff for about three years exploring the possibilities.

“Unless the OEM has done the work to outfit the asset with some sort of sensor package that gives them that data that would allow them to do the prognostics, it's not a feasible option from an aftermarket perspective,” Jakab said. “Now, you can do it with things like engines because with engines. Anybody who says they're going to as an aftermarket telematics company, if they say that they have prognostics, that's going to tell you when something fails, that's a very thin line to walk. And it's very, very difficult to back that claim up. If you have Cummins’ remote diagnostic connection, and you have tens or thousands of engines connected, and you have that as one centralized data repository hooked up to Cummins remote diagnostic connect, they do prognostics, based on a whole bunch of different stuff. And then we receive it back and put that into our portal.”

While Jakab said predictive intelligence will come more directly from OEMs than aftermarket tools, not every sensor device is robust enough to harvest and relay predictive equipment analytics. An exception is the LHP Platform 1.

The TP1 has 4G North America and 3G/2G global coverage, along with Wi-fi, Bluetooth, and Ethernet for local Networking. The device has 2 CAN lines, supports 12- and 24-volt systems and can handleJ1939, CAN Open, MOD TCP and custom 11 bit/29-bit CAN protocols. The TP1, critically, can be set up with advanced triggers that chain logic together along with counting, timing and calculating min/max averages.