Telehandlers are extremely versatile machines to have on jobsites thanks to their ability to complete so many different tasks, like loading (and unloading), picking up, carrying around, moving from place to place, lifting, and placing materials and tools. And their ability to place and retrieve loads at height provides obvious advantages over more traditional construction machines like wheel loaders, skid steers, or vertical mast forklift trucks. This flexibility means that telehandlers are often one of the most highly utilized machines on a jobsite.

It also means that the most common challenge with telehandlers, from a user’s perspective, is selecting the right machine for the job to meet project requirements or jobsite needs. Why? Because these machines have one distinct and dynamic feature—the telescopic quality of the model—that must be considered during the selection process.

With so many different models and size classes of telehandlers to choose from, rental centers need to ask customers detailed questions about the work that needs to be completed to make sure they understand how much weight will require lifting and how much reach is needed to place the load. These two criteria are the starting point in selecting the right model. With this information, you can utilize a telehandler’s load capacity chart to determine which model is right for your upcoming project.

Understanding a Telehandler’s Load Capacity Chart

Since telehandlers also have the unique potential to extend those materials away from the vehicle with the telescoping boom, it is up to the operator of the machine to assure the material it’s lifting, placing, or carrying is within the rated capability of the unit. Understanding the elements that go into the successful placement of a load are vital to effectively using a telehandler.

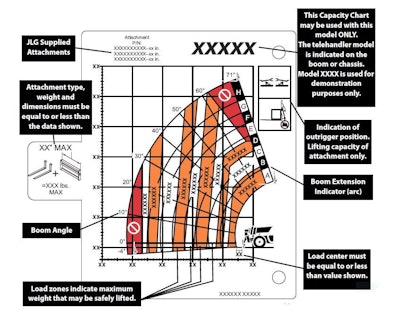

One of the resources you need to consult before using a telehandler is the machine’s load capacity chart. Every telehandler is equipped with one for each of the different attachments it can support, such as a fork carriage, bucket, or truss boom. The load capacity chart highlights two key elements: A telehandler’s operating range and its operating envelope.

- The operating range of the telehandler reflects minimum and maximum boom angles, as well as fully retracted and extended boom positions.

- The operating envelope is located relative to the load center position of the attachment being used.

A sample load capacity chart looks like this:

To effectively utilize the load capacity chart, you must initially determine some basic criteria:

- The weight of the product or material being elevated

- Desired height or reach that needs to be achieved

- The model’s load capabilities

Once equipped with this information, the load capacity chart will provide you with guidance that will allow you to confidently utilize your telehandler. For example, once you have successfully paired the weight and telehandler model, you can use the load chart to assess the load placement or retrieval position. Because boom angles and extensions are an integral part of every load capacity chart, you will use boom angle and extension information to place or retrieve the intended load at the required height and reach.

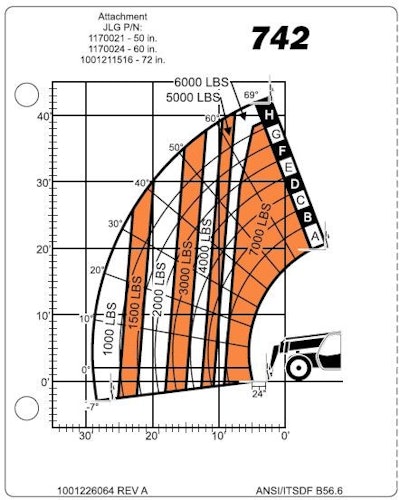

As an example, using the load capacity chart below for reference, if you need to place a 5,000-lb. palletized load (with a load center of 24 in.) at a height of 20-ft. and a reach of 10-ft., the rental store would suggest that you opt for utilizing a fork carriage attachment. Knowing this is the attachment you will be using, when you review your telehandler’s load capacity chart, you would determine that the boom angle indicator should read 40 degrees and the boom extension, visible from the side of the boom, will be the black “D” zone to successfully place the load.

Understanding a Telehandler’s Horsepower Rating

Once you’ve consulted a telehandler’s load capacity chart to understand what size machine you’ll need, you’ll have to decide how much horsepower is needed for the application.

Today’s telehandler engines are regulated by the U.S. EPA under the Tier 4 guidelines, which are based on the engine power and divided into specific power ranges. For each specific power range, the EPA dictates what can be found in a Tier 4 engine’s exhaust, such as particulate matter, and how much of each type of content, as well as emissions, is permissible. Every Tier 4 final telehandler will come with details about how its different engine options meet the current emission regulations.

With the strict engine emission regulations required for Tier 4 compliance, there’s an important breakpoint in the telehandler horsepower ranges to understand—above or below 74 hp (55 kW)—when choosing one engine option over another.

The advantage of engines below 74 hp is that they meet current clean-air standards without diesel exhaust fluid (DEF) after-treatments. For most rental applications, including general construction, a telehandler with a 74-hp engine will deliver plenty of power for machine operations. The compromise with engines above 74 hp is that these machines require the use of DEF.

With multiple choices available for each telehandler model, it’s important to work with your rental center or renter to understand the differences between lower and higher horsepower engine options, which will help determine the right engine type for the jobsite.

By truly understanding project requirements and a telehandler’s load capacity chart and horsepower rating, rental centers will be able to assist you in selecting, and delivery of, the right telehandler for your job — even when it becomes appropriate to swap out machines, if necessary, as the project progresses.