Ben Froland, the product manager of power generation at Hatz Americas, shares his point of view on what's happening within the generator market of the equipment rental industry.

Rental connected with Froland over email in May 2025.

Q. What are the top trends for generators in the equipment rental industry? Why?

Ben Froland, Product Manager - Power GenerationHatz Americas

Ben Froland, Product Manager - Power GenerationHatz Americas

Q. How can rental companies take advantage of these trends?

It’s important to partner with suppliers who genuinely understand emerging technologies. They also must have experience, boots on the ground, working side by side with end users. If you understand the available technology AND you understand the customer’s needs, then you can really tailor the solution for the application. It sounds trite, but a generator just isn’t a generator anymore. Rental companies need to be in the business of providing customer solutions rather than just renting a piece of equipment.

Q. What are the differences between a 2025 generator vs something five/ten years ago?

Ten years ago, we saw the last implementation of the Tier 4 Final emissions requirements for off-highway diesel. This was a major leap in clean diesel technology with massive reductions in particulate matter and nitrogen oxide. Ultra-low sulfur diesel fuel allowed for extended service intervals of up to 1000 hours in some cases. Variable geometry turbos provided nearly instantaneous response to transient loads. These types of clean diesel generators are still very viable options depending on the customer’s needs.

Around 5 years ago we saw widespread use of battery energy storage systems (BESS). Basically, a large battery dropped off on site to be drawn from as needed. Benefits of a BESS include silent operation, zero emissions, no wasted energy, and indoor/outdoor use. The downside for a BESS is when the unit runs out of power it needs to be recharged by something (conventional generator, shore power, solar, etc…) or swapped out. While some had hoped for rapid advancement in battery technology to keep this product class evolving, that just hasn’t happened.

Today, we see the best power generation solutions using a combination of the technologies above. A hybrid generator shares many of the positives of conventional generators and a BESS, while mitigating the negatives. Fewer batteries are needed than in a BESS, resulting in space and weight savings. Diesel is still the most energy-dense fuel widely available, and a small amount can recharge the onboard batteries repeatedly. The batteries are only drained when work is being performed, and the engine only runs when the batteries need to be charged. A hybrid generator doesn’t suffer from range anxiety or a lack of autonomy. The diesel fuel can be topped off with something as simple as a jerry can to extend its useful time on the job site.

Q. What would be the best questions equipment rental companies should ask when considering adding a new generator to their fleet?

Again, be sure to select supply chain partners who understand both emerging technologies as well as customer needs. Ask them about their latest developments and how they are beneficial for the customer and the rental company. The best solutions are environmentally conscious while remaining profitable. If the solution isn’t both responsible and cost-effective, it isn’t the right solution.

It is very important to understand the application of the generator on site for sizing and functionality. Ask what the duty cycle looks like. What is the largest load the unit may see? Is it a motor starting event? Is a variable frequency drive (VFD) or soft starter being used?

With a conventional generator, large fluctuations in current draw may leave the generator oversized and wasting fuel at times. In this case, paralleling multiple smaller generators may be a good solution. Better yet, a hybrid generator could also handle the large inrush and replenish the batteries after the event is over.

Q. What are the latest changes for Hatz?

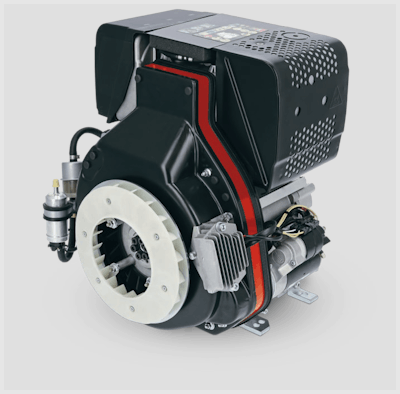

Hatz has had great success with our flywheel-integrated permanent magnet generators in off-highway hybrid machinery. This is our compact, electronic, single-cylinder diesel with integrated windings and battery charger. Many users were still using lead-acid or AGM batteries with these.

According to Hatz, compared to the conventional design of typical engine/generator unit, the flywheel-integrated permanent magnet design reduces the size by 12.4 in and the weight by 37.5 lb. The contactless PMG system has a high degree of efficiency at over 85 percent.Hatz Americas

According to Hatz, compared to the conventional design of typical engine/generator unit, the flywheel-integrated permanent magnet design reduces the size by 12.4 in and the weight by 37.5 lb. The contactless PMG system has a high degree of efficiency at over 85 percent.Hatz Americas

Because the small diesel engine and the digital inverter are both CANbus J1939, the units are ideal for remote monitoring. In fact, with Hatz IoT, the rental company can perform remote diagnostics on the engine as well.

Q. What can we expect on the horizon?

Expect to see more and more hybridization in generators and rental equipment in general. Because of this, we are keeping pace with the market need for higher voltages as power outputs increase. 28V is moving steadily towards 56V. 96V will be coming in the near future and 350V to 400V isn’t out of the question.

Q. Any final thoughts for rental companies?

Yes. In addition to adapting to changes in machinery, be prepared to adapt to changes in business model that accompany new product. Fuel for example is something the customer would contract with the rental company to provide. More fuel-efficient products weren’t necessarily a high priority because the end user ultimately paid for that fuel. With hybrid generators, they aren’t just a little more fuel efficient, they are a LOT more fuel efficient. There is great value in significant fuel savings (monetary, environmental) but the economic value will need to be figured into the rental agreement up front.