Based in Graham, NC, Buckner Companies is one of the nation’s foremost crane, steel and pre-cast erection and industrial rigging firms. Typically, it has 75 to 80 cranes on jobs throughout the continental U.S. and southern Canada. It’s even leased cranes to projects in Alaska and Hawaii.

“There may be a few states we haven’t worked in, but there aren’t many,” says Jeff Holmes, equipment manager.

Getting disassembled cranes, rigging and other equipment to jobsites is challenging because of the size, weight and distances involved. For example, it takes 19 to 26 trucks to transport a crane from North Carolina to Colorado, where it is used to erect windmills. Buckner’s largest crane, the Liebherr LR 11000, requires a caravan of 63 trucks.

Buckner uses outside carriers for large jobs, but the core of its own fleet is eight Western Star 4900 set-back axle trucks it bought in 2012, the first time the company had bought new trucks. The decision to buy new was driven by stricter emissions standards and a desire for better mileage, Holmes says.

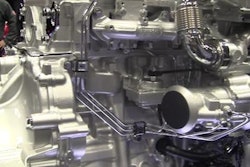

Buckner spec’d four tri-axle trucks and four twin-screws. A ninth unit has a hydraulic crane mounted on back that is used to assemble other cranes. The heavy haulers use Detroit DD15 engines with 18-speed transmissions while the smaller trucks feature Detroit DD13 engines with 13-speed transmissions.

Cutting Costs But Not Corners

Buckner has an annual budget of about $5 million a year moving equipment around the country, a significant portion of which is fuel costs. The Western Star trucks help meet the budget by getting dramatically better fuel economy than the company's previous trucks.

Holmes likes the set-back front axle and high ground clearance on the trucks because they make maneuvering on tight construction sites easy. All of the road tractors have sleeper berths, though Buckner uses that space to store gear and typically puts its drivers up in motels.

“We’ve been really pleased with our trucks,” Holmes says. “They’re just built for rough surfaces. Our typical day is driving out and delivering to the customer, packing up and breaking down equipment and moving on down the road to another customer.”

Cranes and rigging can’t be assembled and put to work unless all the parts arrive. “Reliability is a huge deal,” Holmes says. “We have to get the equipment there on time to meet the contractors’ schedule.”

Holmes says he expects to add more Western Star trucks to Buckner’s fleet.

“They’ve worked really well for us and the support from Western Star and out local dealer has made a big difference, too,” Holmes comments. “When the time comes, we’ll be looking at Western Star again.”

![[VIDEO] Features of Western Star's 4700 Setback Truck](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2016/02/default.56bbae5e9a307.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)