The construction industry is widely considered one of the most dangerous fields of work. In fact, it has experienced more deaths than any other industry since 2008. The most common construction industry accidents come in the form of slips, trips, and falls. One of the leading dangers associated with these sorts of accidents are traumatic brain injuries (TBIs), which can have life-altering and even fatal consequences. When workers fall and hit their heads, the impact happens at an angle, which risks exposing the brain to dangerous rotational motion – which the brain is more sensitive to and can cause severe brain damage or even death. In fact, scientific research shows that rotational motion is among the leading causes of TBIs.

According to a survey from the Bureau of Labor Statistics (BLS) on worksite accidents, 84% of all workers who suffered head injuries were not wearing any head protection. The risk TBIs pose can be alleviated by proper head protection, but only when that head protection is worn correctly. When worn properly, a helmet should fit the wearer’s head snugly, but comfortably, with the chinstrap buckled. When the wearer nods or shakes their head, the helmet should stay firmly in place.

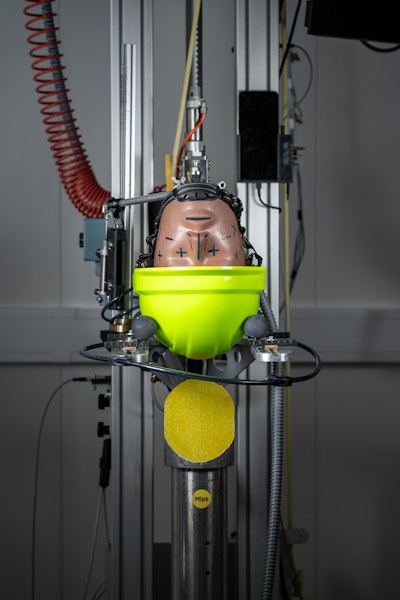

Because of the heightened risk of injury or even death for those in construction, using proper head protection personal protective equipment (PPE) should be an imperative on every jobsite. The safety helmet industry has come a long way in minimizing the real-world risks that workers experience on jobsites. For instance, addressing the danger of rotational motion via the Mips brain protection system for industrial safety helmets. Yet, these efforts can only help to protect when workers chose to wear them and wear them properly. The same is true for nearly every PPE application: Wearing safety equipment according to guidelines is necessary for gear to properly function and minimize danger in case of an accident.

The Mips safety system is designed to work in every sort of helmet, but to optimize safety the best option is to have a properly fastened chinstrap. This is because research indicates that chin straps can increase safety for workers and can play a role in keeping helmets on the wearer’s head in case of an accident. According to Remote Medical International, hard hats with no chin straps can lead to more than 80,000 head injuries per year due to falling off workers’ heads. No helmet provides protection to the wearer if it’s not on the head when the impact occurs.

In the United States, finding the balance between public and individual interests has historically posed a challenge, especially when it comes to public safety. We have seen this with face masks and even seatbelts, which are now one of the most universally well-followed precautions. To understand how the construction industry can increase proper head protection usage, studying the country’s history of resistance to safety measures can provide a helpful key.

The History of Resistance to Safety Measures

Between 1920-1960 the use of automobiles entered the mainstream, causing accidents and injuries to skyrocket from 11 people per 100,000 to 22 people. In direct response, Volvo became the very first car to introduce a 3-point seat belt as standard in 1959 with the Nordic markets, becoming the first car producer in the world to do so. However, by the early 1980s, the majority of Americans still did not use seat belts despite prominent evidence that they helped save lives. In fact, 65% of Americans opposed seat belt law enforcement proposed in 1984, believing that they were “ineffective, inconvenient, and uncomfortable.” Finally that same year, New York became the first state to pass a mandatory seat-belt law, followed by the rest of the United States.

To encourage seatbelt wearing, the auto industry launched a campaign to educate car owners on how seat belts improved safety and the dangerous risks if they didn’t wear one. This helped to shift mentalities on the importance of wearing seat belts while driving.

This kind of pushback is nothing new, and we’ve continued to see it throughout American history. Today, we have seen a similar resistance when it comes to construction workers wearing chin straps. While not all head protection PPE is equipped with chin straps, safety helmets – which are equipped with chin straps – are increasing in prominence, and were even mandated for all Occupational Health and Safety Administration (OSHA) personnel in 2023.

Hard Hats vs. Helmets: A Brief History

Traditional hard hats typically lack chin straps, which can lead to the helmet falling out of place and endangering the worker when they are not upright, move quickly, or experience a fall. Chin straps can play a crucial role in safety because they help keep head protection on the wearer’s head in case of a slip, trip, or fall. Securing the helmet to the head is crucial to ensure the helmet gives the wearer the best-possible protection and to help reduce the risk of TBIs and other head injuries in case of accidents.

Encouraging Proper Head Protection Compliance & Overcoming Safety Resistance

Getting people to properly wear helmets – with the chin strap buckled and secured – has historically proven to be a challenge for the construction industry. Educating helmet-wearers about the risks associated with wearing head protection incorrectly is one way to overcome resistance to taking proper safety measures. Spotlighting the strong correlation between rotational motion and TBIs is another important topic of education to help drive awareness within the construction industry.

In fact, education was a key component in shifting American mentalities in regard to seat belt usage. As it pertains to the safety helmet market, there are indications that safety leaders’ efforts to educate the industry are beginning to pay off: A recent report projected that the safety helmet market could reach $8.1 billion by 2032. However, there’s still much to be done to move the construction industry towards safer helmets: Improving proper head protection compliance is a strong starting point.