We can carpool, take public transportation or buy hybrid vehicles all we want to help save the environment, but the truth of the matter is we will still need roads to ride on. Though the flying car is a recurring symbol of the future, research done in the real world suggests that roads will remain a big part of our future, and if anything our dependency on them will only increase.

Ironically, while the design of the vehicles we drive has gone a long way, the machines, materials and processes we use to construct and maintain our roads today have not changed significantly since the 1940’s. Since only one basic configuration of paver exists today, road maintenance has to be done using machines which were originally constructed for paving new road surfaces.

This has caused road maintenance to develop into a complex and energy-intensive process. It requires multiple machines and creates a severe interference of the traffic in the city every time street maintenance is performed.

Because maintaining the streets generally requires shutting the traffic down, there is constant pressure on the road working agencies to delay minor repairs until the road condition becomes so bad that the road needs to be torn down completely and paved again using new materials.

The Dynapac Red Carpet is an environmentally conscious solution for road maintenance in future Mega-Cities, where street traffic is predicted to become increasingly dense and unstoppable. This futuristic road-recycling paver allows inner city traffic to continue its flow without interruptions by letting vehicles drive over it while paving.

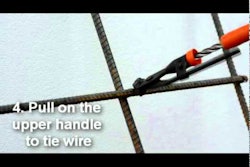

The machine utilizes an existing process known as Hot-In-Place Recycling. The front of the machine contains a large microwave heater. Microwaves heat the stones which compose the upper road layer, and they in turn heat the asphalt binder returning the pavement to its original soft state. The following mechanical brushes remove the soft asphalt and scoop it into a large mixing tank. In this tank the asphalt is mixed with a small amount of fresh binder, and paved back onto the road using a screed. Then, a set of rollers at the back of the machine compact the new pavement. The slow movement of the machine means the recycled pavement that it leaves behind is ready for immediate use by oncoming traffic. While road work is being performed, traffic can keep on flowing uninterrupted over the machine’s integrated ramp.

The paver is powered by electro-hydraulic engines housed in the wheel hubs. The refilling of new binder is performed via a quick refill hatch in the right console of the vehicle.

The project was developed in close collaboration with Dynapac, a leading manufacturer of road paving equipment, and with constant feedback from NCC Roads, one of the largest construction companies in the Scandinavian region. Work processes included multiple field trips, on-site observations, mockups and interviews with road engineers, road workers, operators and manufacturers of paving machines in Sweden and Germany.

This project looks forward to the development of large Mega-Cities, and aims to create an alternative, low energy and a more environmentally conscious concept for maintaining the transport arteries in urban areas.

Click for additional photos and information on the Dynapac Red Carpet.