Finding ways to build better, longer lasting roadways has been a task many in the asphalt industry have been challenged with for years. There are constant innovations in our industry to do just that, but putting a new type of pavement down on a roadway for the traveling public to test is not only risky, but the price of failure is just too high.

This is why facilities like the National Center for Asphalt Technology (NCAT) were developed. Established in 1986 as a partnership between Auburn University and the National Asphalt Pavement Association (NAPA) Research and Education Foundation, the goal of NCAT is to provide practical research and development to meet the needs of maintaining America's highway infrastructure. Their mission is to ensure the industry's ability to provide pavements that are durable, sustainable, quiet, safe and economical.

A 1.7 mile test track was created at NCAT as a real-world laboratory that allows for cutting-edge experimentation while avoiding the risk of failure on actual roadways. The track is comprised of 46 200-ft test sections funded as a cooperative project among highway agencies and industry sponsors. Research experiments based on single test sections or groups of test sections provide sponsors the confidence to move concepts into practice, saving state departments of transportation millions of dollars each year (see sidebar).

Partnerships Advance Pavement Design

In order to fund its research, NCAT partners with state highway agencies, the Federal Highway Administration and the highway construction industry to develop and evaluate new products, design technologies and construction methods that quickly lead to pavement improvements. 80% of the funding for the NCAT test track comes from partnering with state DOTs.

The range of products and processes under trial at the test track, now in it's seventh cycle, illustrates some of the challenges faced by road owners and the paving industry. Among them rejuvenators, bio-based products, balanced mix design and deep single layer  At the test lab, NCAT researchers have improved aggregate testing and evaluation methods, developed mix design procedures for stone matrix asphalt, evaluated modified asphalt mixtures, improved mix design and control methods to minimize rutting, and developed a test to measure asphalt content without using solvents.

At the test lab, NCAT researchers have improved aggregate testing and evaluation methods, developed mix design procedures for stone matrix asphalt, evaluated modified asphalt mixtures, improved mix design and control methods to minimize rutting, and developed a test to measure asphalt content without using solvents.

For example, the Texas Department of Transportation (TxDOT) and Oklahoma DOT are testing out their new balanced mix design approach and comparing it to a section designed using the Superpave volumetric approach. TxDOT’s balanced mix design specification uses a Hamburg wheel tracker to evaluate resistance to rutting and moisture damage and the overlay test for assessing cracking resistance.

Read Next: NCAT Tests Preservation Techniques

Oklahoma’s approach combines the Hamburg wheel tracker with the Illinois Flexibility Index [Texas Sections S10 and S11; Oklahoma Sections N9, S1].

South Carolina DOT has already experimented with replacing between 4-5-in. in a single pass. Now it wants to look at a 7-in. deep section. Embedded thermocouples and thermal imaging while the section was laid will help answer questions about how such a deep section cools, and pressure plates and strain gauges have been embedded in the pavement to measure long-term structural response.

Other technologies and issues under test for this cycle include thinner overlays, fogseal, reflective cracking and density of asphalt. Work on seven sections of test track continues from previous cycles as part of the Cracking Group Experiment, as well as ongoing tests to evaluate other mixes and approaches for various DOTs.

NCAT also works with product manufacturers to test their products under "real-world" conditions.

"Many of these sponsors know the value of their product and that it will perform, they just want the research data to prove it to the world," Buzz Powell assistant director at NCAT says. "Through these partnerships, we give them the data they need to prove it outside of the lab."

Delta S from Collaborative Aggregates is a bio-based rejuvenator already under test at NCAT. A section of road containing 35% RAP and the rejuvenator was laid in 2018 and is being compared to a control section containing 20% RAP.

New with this test cycle is a biopolymer modifier which comes from soybean oil. The United Soybean Board, which is sponsoring research at Iowa State University, is also sponsoring a surface mix produced with PG 76-22 bitumen modified with the biopolymer. This will be measured up against a mix containing the same ingredients, apart from a conventional polymer. [Section W10]

Cold Climate Performance

NCAT has partnered with MnROAD, a pavement test track owned and operated by the Minnesota Department of Transportation (MnDOT), for a parallel study for both northern and southern climates. NCAT and MnROAD are the nation’s two largest full-scale pavement testing facilities where using real construction methods and live trafficking under actual climate conditions provides an authentic environment for researchers to study and evaluate the performance of materials used in roadway construction.

While NCAT uses trucks that simulate traffic, MnRoad's Mainline test section (to the right) is an actual section of Interstate 94 being driven on my the traveling public. The mainline test section is 3.5-miles of Interstate traffic diverted from the parallel westbound I-94 between Albertville and Monticello, MN.

While NCAT uses trucks that simulate traffic, MnRoad's Mainline test section (to the right) is an actual section of Interstate 94 being driven on my the traveling public. The mainline test section is 3.5-miles of Interstate traffic diverted from the parallel westbound I-94 between Albertville and Monticello, MN.

Read Next: How Project Research & Sustainable Initiatives Saved the Illinois Tollway Nearly $250M

While NCAT uses trucks that simulate traffic, MnRoad's test section is an actual section of Interstate 94 being driven on my the traveling public. The mainline test section is 3.5-miles of Interstate traffic diverted from the parallel westbound I-94 between Albertville and Monticello, MN.

MnROAD collects detailed pavement performance data along with thousands of pavement sensors located in each test section.

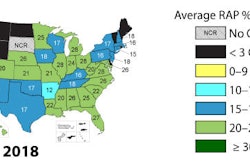

Like NCAT, MnRoad relies on sponsors who want to collect data on their products. Cargill has put its Anova bio-based rejuvenator to the test on both the NCAT test track and at MnRoad. The company’s rejuvenator will be used in a mix with 45% RAP and its performance compared to a section with lower proportions of RAP. [Section N3] The aim, Cargill says, is to evaluate Anova’s performance in both southern and northern U.S. climates.

To further the research at MnRoad, the National Road Research Alliance (NRRA) was created. Their goal is to develop a mandate to improve the future sustainability of our roads through research and a commitment to cooperative implementation. The alliance sponsors research at the MnROAD test track. The alliance consists of state DOTs, private companies, academic institutions and associations. Together, they make the decisions for MnROAD construction and research.

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)