Asphalt pavements are made with various types of aggregate materials along with a binder to hold them all together and are designed to let minimal amounts of liquid pass through them. This design is intended to keep moisture away from the underlying layers which prevents damage to the entire pavement structure.

In contrast, the primary function of a porous or permeable pavement is to allow water to run rapidly through the surface to a sub-layer, which allows general or directed drainage. Porous asphalt pavements are gaining awareness and acceptance in the industry as good solutions in areas where drainage is an issue.

This means they are commonly used for parking lots and other light-duty applications. Full-depth porous asphalt pavements are increasingly being used on roadways as part of efforts to mitigate flooding hazards, reduce hardscape and improve sustainability.

Porous Asphalt Explained

According to the National Asphalt Pavement Association (NAPA) the secret to a successful porous asphalt pavement is to provide the water with a place to go, usually in the form of an underlying, open-graded stone bed. As the water drains through the porous asphalt and into the stone bed, it slowly infiltrates into the soil.

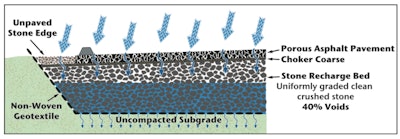

A typical porous asphalt pavement consists of a porous asphalt course, a top filter course, a reservoir course, an optional bottom filter course, filter fabric and existing soil or subgrade material. The porous asphalt course consists of a 2- to 4-in. thick open-graded asphalt layer. The pavement should be a mix containing little sand or dust, with approximately 16 percent voids. Typical cross-section of a porous asphalt pavementNational Asphalt Pavement Association

Typical cross-section of a porous asphalt pavementNational Asphalt Pavement Association

Pavement designers recommend a top filter course, 2 inches thick, using 1/2-inch crushed stone aggregate. The filter course provides filtration and also protects the reservoir course during placement of the asphalt mix.

One of the main purposes of the filter course is to provide a firm paving platform. Without this layer, the single-size, open-graded aggregate may be unstable under the paver.

While the mix is different than typical pavement designs, there are no proprietary ingredients to be manufactured when creating porous asphalt mixes and most asphalt plants can easily prepare the mix. Installation of the mix also does not require specialized paving equipment or skills so general paving contractors can install it as they would other paving projects.

Longterm Benefits

While special features such as the underlying stone bed are more expensive than conventional construction, these costs are more than offset by the elimination of many elements of standard storm-water management systems. On those jobs where unit costs have been compared, a porous asphalt pavement is generally the less-expensive option.

NAPA also says the cost advantage is even more dramatic when the value of land that might have been used for a detention basin or other storm-water management features is considered.

Porous asphalt will also save you money because it eliminates the need to put in a storm-water management solution such as a retention pond. The land that is normally slated for the retention pond can be developed and used as a profitable asset that adds value to the property.

There are a few key design and maintenance factors to consider in order to ensure optimum pollutant removal and longevity of porous asphalt pavements:

- Placement in areas with highly permeable soils; if underlying soil is damp, microbiological decomposition of pollutants may be impeded

- Existence of organic material in soil

- Vacuum sweeping on a quarterly schedule

- Use in low-density parking areas

- Restrictions on use by heavy vehicles

- Limited use of de-icing chemicals

- Inspection and enforcement of specifications during construction

- Pretreatment of runoff to paved area

- Implementation of a sediment control plan

- Extending the depth of reservoir level to below the frost line to prevent subgrade from frost heave

When properly installed and maintained, porous asphalt pavements can have a minimum service life of 20 years.

![Lee Boy Facility 2025 17 Use[16]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/09/leeboy-facility-2025-17-use16.AbONDzEzbV.jpg?ar=16%3A9&auto=format%2Ccompress&fit=crop&h=135&q=70&w=240)