How many times have you been delayed on construction projects when you don’t have all the necessary approvals needed in time to order materials and keep the job moving? For example, forgetting to get the concrete foundation design mix approved by the structural engineer can stop a scheduled concrete pour for days. Or when constructing concrete tilt-up or masonry building walls, you need to order the hollow metal door frames weeks in advance to have them manufactured per the exact opening sizes, door schedule and finish hardware specifications. Another challenge is when the owner and architect can’t agree or decide which ceramic tile to choose until the week before tile is needed on the job. And when the tile is finally chosen, they likely pick one that comes from Italy and takes 16 weeks to get delivered.

These and many other approval problems happen on construction projects every day. And to make situations worse, the time delay and increased costs associated without obtaining timely approvals are then blamed on your company, your suppliers or other culprits who should have known and were delaying the approval process. As a construction consultant, I have observed many disputes that ended up in court and cost hundreds of thousands of dollars in delays, wrong products and non-authorized substitutions of materials that weren’t specified but installed without proper approvals.

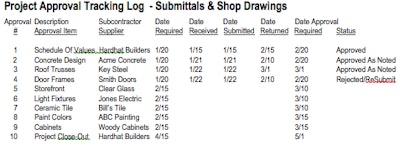

By implementing a proactive approval process and not waiting for your subcontractors and suppliers to submit their required shop drawings and submittals whenever they get around to it, you’ll stay ahead of the game, avoid potential delays, and not allow the owner or architect to slow you down.

Assume everything needs approval before you install it

After you get hired to build a project, go through the contract and specifications (if there are any) to determine what actual approvals are required. If no specific instructions are outlined, still assume you’ll be required to obtain prior approval before you install any and every material, product, fixture, finish, color, structural component like trusses or steel beams, or custom shop fabricated item like cabinets or toilet partitions. Don’t forget anything visible to the eye when the job is completed including concrete textures, glass, storefront, landscape plant materials, fire sprinkler heads, ceilings, walls, flooring, lights, or air conditioning grilles.

Approvals can also be required on more than products, materials and finishes, too. Approvals can be required by the owner, architect, engineers or lender on your subcontractors and suppliers, payment cost breakdown or schedule of values, work plans or proposed schedule, milestones, proposed supervisors and project managers, testing company, jobsite logistics plan, or insurance policy and coverage limits. When you don’t ask in advance whether approvals are needed for these items, the owner or architect can stop your project or payment application until you get an item approved they deem necessary.

Create an approval plan

To create a simple project approval standardized system that works, take a few moments to sit down with your project managers and superintendents. Brainstorm to make a master list of everything you can think of on every type of project that might need the owner’s or architect’s approval. Print this completed list and use it as a company-wide project approval checklist to fill out before you start every job. When awarded a contract, the project manager and contract administrator can review the project documents to determine which approvals they anticipate will be needed. Don’t forget to include long lead items and important project specific equipment and finishes affecting your schedule as well.

Get your list approved

Next meet with the project customer, owner or architect to submit your proposed project submittal, shop drawing and approval list for their review and approval. Include each item needing approval and the deadline required for approval to keep your schedule moving forward on-time. Include on your list all the items you’ll be requesting to substitute as an alternative or an equal to the specified material or item on the plans or specifications. Then explain to your customer that if the approval deadlines aren’t met, the project will be delayed and you’ll expect to be compensated for all delay costs associated with their slow processing or approval time beyond the schedule requirements.

It is imperative you insist your subcontractors and suppliers make their approvals a priority as well. When awarding contracts to them, tell them up front what you require and the drop dead deadlines for submitting their shop drawings and submittals for approval. Put these dates in writing in their contracts or purchase orders and then manage the process tightly. Put your contract administrator or field superintendent in charge of managing the shop drawing and submittal approval process. Meet with them weekly to review the progress and address any slow or missing approvals.

George Hedley CSP CPBC is a certified professional construction BIZCOACH and popular industry speaker. He helps contractors grow, make more profit, build management teams, improve field productivity, and get their businesses to work for them. He is the best-selling author of “Get Your Construction Business To Always Make A Profit!” available on Amazon.com. E-mail [email protected] to sign-up for his free e-newsletter, start a personalized BIZCOACH program, attend a 2 day BIZ-BUILDER Boot Camp, or get a discount at www.HardhatBIZSCHOOL.com online university for contractors. Visit www.HardhatPresentations.com for more information.