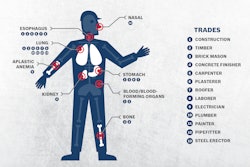

Being covered in concrete dust is a reality that many workers face everyday. From cutting and coring to concrete grinding, these floating particles are an unavoidable nuisance. However, as many are unaware, the so called nuisance is more dangerous than meets the eye. The concrete dust, aka crystalline silica, negatively impacts countless lives daily by attributing to silicosis, lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease. That is why on August 23, 2013, the Occupational Safety and Health Administration (OSHA) proposed new standards to toughen its regulation of silica dust exposure.

But how can such a small speck of dust cause so much damage? Silica dust is a slow acting agent that does not pose a problem until it is too late. Dry concrete grinding or cutting fills the air with harmful silica dust throughout the entire jobsite. Even though all the particles may not be visible to the naked eye, the dust is still present.

Silicosis results from exposure to low concentrations of silica dust over a long period of time, which usually spans from ten or more years. This slow process lures contractors into a false sense of hope that their health is unaffected, but their lungs are slowly deteriorating. Lungs are naturally able to filter out regular dust and dirt, but silica dust is too small for the lungs’ filtering system to be effective at least 100 times smaller than ordinary sand found on beaches and

playgrounds.

The dust particles are like microscopic shards of glass that damage the lining of lungs, which can cause fluid buildup and scar tissue that cut down your ability to breathe. Unfortunately, there is not a cure for silicosis yet, but it is avoidable by practicing safer methods and using appropriate equipment.

With OSHA’s proposed new regulations, they estimate to save more than 600 lives and prevent more than 1,500 new cases of silicosis per year. Currently, the daily permissible exposure limit (PEL) is about 100 μg (micrograms)/m3 for most industries. OSHA is proposing to cut this limit in half to 50 μg/m3, averaged over an eight hour day throughout ever industry.

The current standards do not offer enough protection for workers. The current PEL for silica was established in 1971, and since then, studies have shown that workers are can still get sick or die when exposed to silica at these permissible levels. The rule would require:

- Provisions for measuring how much silica workers are exposed to.

- Limiting workers’ access to where silica exposures are high.

- Using effective methods and equipment to reduce exposure.

- Providing medical exams.

- Properly training workers about silica related hazards to name a few.

Simple ways to drastically reduce silica exposure are through vacuums, masks and wet cutting methods. Using equipment with an attached vacuum system significantly lowers the possibility of concrete dust escaping into the air. Industrial vacuums with HEPA filters and strong suction power will provide the best results because they are specifically designed for this line of work.

Wearing properly fitted masks are extremely beneficial when limiting silica exposure. Instead of wearing masks that came off the store shelves, invest in a custom fit mask that is specifically designed to block out refined particles like silica dust. Store bought masks are not meant to work effectively against these small particles for long periods of time.

Furthermore, one of the most effective methods would be applying water to every cut or grind. By using water to subdue the concrete dust, it alleviates workers from silica exposure. Although some workers may be hesitant to switch to a wet method, there are a few benefits. For example, it helps save the life of the tooling, which in turn saves money. And slurry clean up has been simplified through slurry solidifying products like Gelmaxx. The product turns the wastewater into a solid byproduct that is safe to dispose in the dumpster.

By taking the time now to slowly improve work practices, invest in proper equipment, and train workers, it will provide a much smoother transition once the rule becomes finalized.

Ed. Note: Last month, OSHA issued the final rule on silica dust exposure. The goal of the new rule is to curb lung cancer, silicosis, chronic obstructive pulmonary disease and kidney disease in America's workers by limiting their exposure to respirable crystalline silica. The rule is comprised of two standards, one for Construction and one for General Industry and Maritime. Read more about the final rule here.

Paul Nyguen is a representative from GelMaxx Slurry Solutions. He can be reached at [email protected].