When craftsman restore natural stone the goal is to restore the polish to the same high degree of clear reflective polish when originally installed. The Concrete Polishing Association of America (now the Concrete Polishing Council (CPC), a division of the American Society of Concrete Contractors (ASCC) was founded on this principal. The challenge was to teach concrete polishers this concept; to have them understand the difference between simply creating a shiny surface compared to one that had high reflective clarity. Even harder was to teach architects, designers, general contractors and owners this concept. A floor with a high degree of reflective clarity is more durable and sustainable than one that is simply shiny. As a concrete polisher it was hard to bid jobs and even more difficult for the person evaluating proposals when one price may represent durability and sustainability, while the other represented a shiny floor with a lower life cycle. At the time, basic gloss meters were used to evaluate the degree of specular gloss but lacked the ability to distinguish the quality of that specular gloss. In early 2011 Brad Burns, then the sitting President of the CPAA found a portable device that would read Distinction of Image (DOI). Simply put it reads the reflective clarity of the specular gloss of the polished finish.

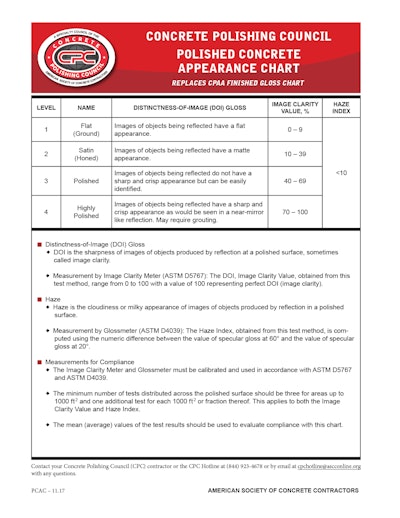

The CPC recently released the, “Polished Concrete Appearance Chart” which replaces the CPAA, “Finished Gloss Chart.” The CPAA, “Finished Gloss Chart” used both 60 degree specular gloss and DOI to quantify the polished surface. Although, it did not specify a haze index requirement. The new document was created for two reasons -- 60 degree gloss is easily manipulated compared to achieving a high DOI in combination with a Haze below 10. DOI in combination with haze is an indicator of surface profile, quality of the mechanical interaction between abrasives and the surface and sustainability of the polished surface.

Defining Gloss

Gloss is a general description of specular reflection. Specular reflection is the difference between the total amount of light (incident) and the proportion of light reflected back. Gloss is overly used as a generic term to describe reflected light without regard to the visual properties of that reflected light. Specular, Sheen, Contrast, Haze, Distinction of Image and Absence of Surface Texture Gloss are the six different properties of gloss.

Specular gloss is the perceived brightness and brilliance of highlights and is defined as the ratio of the light reflected from a surface at an equal but opposite angle to that incident on the surface.

Sheen gloss is the perceived shininess at low grazing levels and defined as the gloss at grazing angles of incidence and viewing.

Contrast gloss is the perceived brightness of the specularly and diffusely reflecting areas and defined as the ratio of the specularly reflected light to that diffusely reflected normal to the surface.

Absence of Bloom, also known as Haze, is the perceived cloudiness in reflections near the specular direction defined as a measure of the absence of haze or milky appearance adjacent to the specularly reflected light.

Distinction of Image is the perceived distinction of images reflected in surfaces and defined as the sharpness of the specular light.

Absence of Surface Texture Gloss is defined as the uniformity of the surface in terms of visible texture and defects such as orange peel, scratches and inclusions.

Concrete Polishing Industry

When references are made about gloss meters or gloss readings technically what is being referred to is specular gloss. Gloss (ASTM D523-14) is measured in Gloss Units (GU) and range from 0 – 100. Gloss is measured at different angles depending on the material and it’s reflective qualities. The most used angles are 20, 60 and 85 degrees. The concrete polishing industry has traditionally used 60 degree measurements. Other industries will use 20 degree when the 60 degree reading is above 70 and 85 degree is used when the 60 degree reading is below 10. The change in angle reading is performed when more precise measurements are needed when comparing the specular gloss of finishes. In essence you are increasing the resolution of your specular gloss measurement.

Specular reflection gloss readings are good indicators of the gross amount of light reflected from the surface but it does not quantify the quality of the reflected light. Parameters to read DOI, Haze and Rspec provide numerical readings that quantify surface finish quality.

As a standalone measurement DOI (ASTM D5767-17) provides information to quantify surface profile and visual characteristics of surface finish. DOI is calculated using the 20 degree reflection since it is a higher resolution reading and measure on a scale of 0 - 100. DOI is an indicator of surface texture. To achieve a high DOI the surface profile when measured at one millionth of an inch is extremely low. DOI is an indicator of a highly sustainable surface based on the hardness and density of the material the surface is made from. Smooth surfaces wear less than rough surfaces.

Other parameters such as haze (ASTM D4039-09(2015) and E430) can be an indicator of an improper polish, dried densifier, resin transfer from diamonds, guard like products or impregnator not removed from the surface. Haze is the whitish blushing coloring seen in reflections that diminishes contrast within the reflection sometimes throughout the entire reflection and sometimes just along the edges of reflected objects. ASTM D4039 determines haze be reading specular gloss at 20 and 60 degree angles and calculated as the difference between the two. ASTM E430 is performed with three test methods. The first method reads specular gloss at 30 and 28 or 32 degrees for narrow angle haze and 25 or 35 degree for wide angle reflection haze. The second reads specular gloss at 20 degrees and 18.1 and 21.9 degrees for narrow angle reflection haze. The third reads specular gloss at 30, 28 or 32 degree for narrow angle reflection haze and 15 degrees for wide angle reflection haze.