Injecting polyurethane foam at various depths, in areas where soil problems exist is not new. The process has been deployed for decades but protected by patents which limited the number of contractors providing the service.

Now with patents expired and foam concrete repair technology blooming, many firms may wish to evaluate the introduction of this emerging repair alternative to service governmental, commercial and even residential markets. The process is fast, permanent, non-obtrusive, highly profitable and may require less capital commitment for entry than historic compaction grouting and piering systems.

What is Deep Foamjection?

In November 2013, I previously wrote an article touting the profitable expansion of polyurethane concrete lifting system’s vs. traditional mudjacking/slabjacking processes. (“Heavy Lifting”) Since that time the polyurethane concrete lifting industry has exploded. That is injecting mixed two part polyurethane foam liquid components under a slab of concrete allowing the expansion effect of the chemical reaction to lift the slab. Technology developments with foam formulas now have many alternatives in the market to address the control/speed and strength issues the naysayers initially presented as reasons why this would not be profitable or popular.

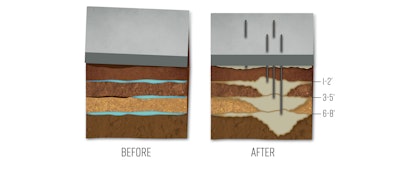

Deep Foamjection uses the same basic process and equipment. Instead of injecting the liquid Part A and Part B mix just under a slab you are injecting like or comparable mixed liquid foam components at nearly any depth through especially designed pipe systems which you drive to various depths depending on need.

The material is introduced into to the subterranean environment as a premixed liquid. When the liquid solidifies into a foam underground, it acts like mother nature’s tree root systems:

- Expanding to compact week soil areas

- Filling Voids

- Binding Soils

Deep Foamjection uses the same basic process and equipment. Instead of injecting the liquid Part A and Part B mix just under a slab you are injecting like or comparable mixed liquid foam components at nearly any depth thru especially designed pipe systems which you drive to various depths depending on need.Paul DelFino

Deep Foamjection uses the same basic process and equipment. Instead of injecting the liquid Part A and Part B mix just under a slab you are injecting like or comparable mixed liquid foam components at nearly any depth thru especially designed pipe systems which you drive to various depths depending on need.Paul DelFino

Simply stated it stabilizes and strengthens the environment mitigating the root causes of a structure, road, or a concrete pad from settling. Basic concrete lifting may or may not be a permanent solution since the end result of injecting mud or polyurethane just under a slab and getting lift is only as good as the environment it is sitting on. With Deep Foamjection you are addressing the root cause of the problem at various depths.

What's Important

The Foam – There are countless foam types, formulas, manufacturers and distributors ready to supply you. However – with Deep Foamjection, special care must be taken to pick a partner/supplier that offers a truly hydrophobic foam.

Water is a primary cause of many of the problems. Truly hydrophobic foams set up in water, displace water when setting up, and will not lose strength/density when injected into a wet/moist environment.

Carefully formulated and controlled set up speed is also important. Not just any foam will do! Foam deployed for Deep Foamjection must enjoy characteristics of set up speeds of the mixed liquid to allow travel time to the depths desired before solidifying or all you will do is fill up a pipe with foam.

The Weight – Highway Engineers have traditionally appreciated the value of Deep Foamjection since unlike mudjacking or compaction grouting the repair does not add more stress WITH WEIGHT to an already week environment.

Speed and Unobtrusive Benefits – Deep Foamjection projects do not require excavation and the related introduction of heavy equipment to the environment like backhoes and concrete pumps. Deep Foamjection projects are clean with a minimum of heavy labor. To offer a perspective, consider the fact that a 14-ft. polyurethane trailer pulled by pickup caries all the equipment necessary as well as two 55 gallon barrels of the material. This is equivalent to two concrete mixing trucks of fill/material when installed.

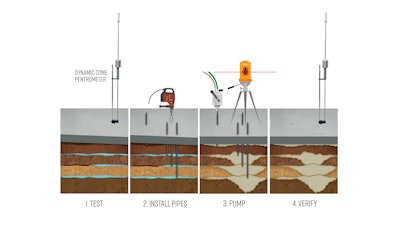

Immediate, Measurable Results – Most Deep Foamjection contractors are equipped with a dynamic cone penetrometer. This simple tool allow contractors to take soil compaction readings before and after the work is complete to meet engineered standards.

An Air Purged System – For efficiency polyurenthane injection processes utilizing “air purged” equipment is preferred. Air purged systems drive a continuous flow of air into the pipe and target injection area throughout and after the injection process. This pushes all liquid thru the pipes to desired depths and keeps the pipes open for additional injections until desired results are achieved. Without an air purged system you will be continuously driving more pipes and dramatically increasing your costs.

Pictured here is the Deep Foamjection process from start to finish.Paul DelFino

Pictured here is the Deep Foamjection process from start to finish.Paul DelFino

What Work Can Be Done

- Structure settling problems can be mitigated. (In some cases structures can be lifted safely.)

- Highway and bridge environments can be stabilized, leveled and reinforced.

- Equipment pads can be stabilized, lifted and leveled.

- Retaining walls can be reinforced.

- Sea walls can be reinforced and stabilized while mitigating future deterioration of wave and wake action. (The foam is hydrophobic and will set up and remain stable in water.)

Although Deep Foamjection is not a 100% replacement solution for various piering system types and compaction grouting approaches, it will allow contractors to complete a large percentage of repairs without the negatives of these traditional approaches. Deep Foamjection can also be complementary to some piering applicants when it cannot be a full alternative. Quite simply Deep Foamjection is:

- A less expensive install solution

- A less obtrusive and cleaner install solution

- A faster install solution

The Bottom Line

In the end we all do what we do and read articles like this to make more money. Contractors can enter the Deep Foamjection and Polyurethane Concrete Repair business with an investment of approximately $60,000 for equipment and training. Partnerships with foam supplier experts can include project support to bridge the learning curve. Simply stated, it is not unreasonable for your first project to fund your startup investment. It is likely the business entry will provide a future that will have you enjoying:

- Higher profit margins

- Capacity to complete more projects

- Competitive advantages

It truly makes sense for all contractors in the trade to evaluate the introduction of Deep Foamjection. Or better said – do not be the last in your market to evaluate the fit in your business.

About the author

Paul DelFino is a principal in the consulting firm Opportunity Inc. For nearly three decades he has assisted entrepreneurs in growing their businesses, responding to economic swings and merger and acquisition activity.