Cold weather is rapidly approaching but, as a contractor, you may have project obligations to fulfill, regardless of the weather. In fact, you may be ordering, placing, and curing concrete in cold weather—an ambient environment that can have an unfavorable effect on the set time, strength development and overall durability of the concrete—if precautions are not employed.

Do you know what to do to ensure that concrete placed in this environment develops the correct strength and durability? The correct selection and use of concrete admixtures along with other steps can be an effective means in which to protect the quality and durability of the concrete. Follow these tips for a successful project in cold weather.

Before we continue, let’s talk about what constitutes “cold weather.” According to the American Concrete Institute (ACI) Committee 306, cold weather is defined “as a period when for more than three consecutive days the average daily air temperature is less than 40º F (5º C) and the air temperature is not greater than 50º F (10º C) for more than one-half of any 24-hour period.” The average daily air temperature is the average of the highest and the lowest temperatures occurring during the period from midnight to midnight.

Table 1. Setting Time of Concrete at Various Temperatures.Source: Concrete Construction, March 1990

Table 1. Setting Time of Concrete at Various Temperatures.Source: Concrete Construction, March 1990

Figure 1. The Effect of Low Temperature on Concrete Compressive Strength.Source: The Portland Cement Association, "Design and Control of Concrete Mixtures"

Figure 1. The Effect of Low Temperature on Concrete Compressive Strength.Source: The Portland Cement Association, "Design and Control of Concrete Mixtures"

Low temperatures can have a beneficial impact on the hardened concrete properties as recognized by ACI Committee 306 and in ACI 306R, “Cold Weather Concreting”, “one should take advantage of the opportunities provided by cold weather to place low-temperature concrete. Concrete placed at low temperatures [40-55º F (5-13º C)], is protected against freezing and receives long-time curing develops a higher ultimate strength and greater durability. It is less prone to thermal cracking than comparable concrete place at higher temperatures.”

What Not To Do

In sub-freezing weather conditions, setting time, strength development and durability characteristics of concrete that is not adequately protected will be severely affected. To avoid this consequence, the following are examples of what not to do:

- Concrete should not have a water-cementitious materials ratio exceeding the limits recommended in Table 2 of ACI 201.2R, Guide to Durable Concrete

- Concrete should not be exposed to cycles of freezing and thawing while in a saturated condition or in service should be properly air-entrained

In addition:

- Concrete in the plastic state will freeze when the mixture temperature falls below 29º F (-2º C) and is left undisturbed for a sufficient time for ice to form. Once ice has formed, normal hydration will not occur, and concrete setting time will be seriously impaired

- Concrete that has frozen during the first 24 hours can experience up to 50% loss in compressive strength at 28 days

- Concrete that is protected from freezing until it has attained a compressive strength of at least 500 psi (3.5 MPa) will not be damaged by exposure to a single freezing cycle

- Concrete should not be allowed to freeze and thaw in a saturated condition before developing a compressive strength of 3,500 psi (24 MPa).

All concrete must be protected from freezing until it has reached a minimum strength of 500 psi, which typically happens within the first 24 hours. If concrete freezes while it is still fresh or before it has developed sufficient strength to resist the expansive forces associated with the freezing water, ice formation results in the disruption of the cement paste matrix causing an irreparable loss in strength. Early freezing can result in a reduction of up to 50% in the ultimate strength.

Once concrete has attained a compressive strength of around 500 psi, it is generally considered to have sufficient strength to resist significant expansion and damage if frozen.

What To Do To Ensure Performance

There are established cold weather concreting practices that will ensure satisfactory concrete performance. The objectives of these practices are to:

- Maintain curing conditions that foster normal strength development

- Assure that the concrete develops the required strength for safe removal of forms

- Prevent damage to concrete due to freezing at early ages

- Limit rapid concrete temperature changes to withstand induced thermal stresses

- Provide protection with the intended serviceability of the structure

In hardened concrete, cold weather can increase the potential for differential thermal cracking (high concrete temperature/low ambient temperature) and permeability to occur. Generally, cold weather concrete practices employed for regular concrete can be applied to decorative concrete with the exception for the use of accelerating admixtures in the concrete mixture. The use of a chloride bearing admixture should never be used in a decorative concrete mixture and the use of a non-chloride accelerator needs to be consistent throughout the entire loads in the placement to ensure there is no color variation. The timing of the finishing is key, you don’t want to finish different placements at different times, which can cause color variations. As mentioned previously, even with decorative concrete, prevent the concrete from freezing before it reaches final set.

Remember, the rate of setting depends on the temperature of the concrete. Concrete typically “sets” in six hours at 70º F (21º C), with no set control admixtures used in the mixture. At lower temperatures, the set rate is decelerated, losing 33% of the set time per every 10-degree decrease in ambient temperature. At temperatures lower than 70º F (21º C), the set time is lengthened. Ultimately, a severe loss of up to 50% of the strength could be lost in concrete that is not protected or cured properly.

What Affects the Temperature of Concrete When Batched?

Although more of a concern for ready mix concrete producers, contractors should also understand what affects the initial temperature of concrete and what measures, if any, can be taken to meet project specification requirements.

Concrete temperature at the time of mixing is influenced by temperature, specific heat and quantity of its ingredients. The approximate temperature of concrete can be calculated from the following equation:

T = [0.22 (TsMs + TaMa + TcMc) + TwMw + TsMws + TaMwa]

[0.22 (Ms + Ma + Mc) + Mw + Mws + Mwa]

where:

T = final temperature of the concrete mixture

Tc, Ts, Ta and Tw = temperature of cement, fine aggregate, coarse aggregate and water, respectively

Mc, Ms, Ma, Mw, Mws and Mwa = mass of cement, saturated surface-dry fine aggregate, saturated surface-dry coarse aggregate, mixing water, free water on fine aggregate and free water on coarse aggregate, respectively.

The temperature of concrete can be increased by 1º F (0.5º C) by increasing:

- Cement temperature by 8º F (4º C)

- Water temperature by 4º F (2º C)

- Aggregate temperature by 2º F (1º C)

Of all the concrete-making materials, water is the easiest and most practical to heat. The mass of aggregates and cement in a concrete mixture is much greater than the mass of water. However, water can store five times as much heat as can solid materials of the same mass.

Table 2. Recommended Concrete Temperatures. For colder weather, a greater margin in temperature is provided between concrete as mixed and required minimum temperature of fresh concrete in place. For Line 1, maximum placement temperature is minimum temperature in the table plus 20 degrees F (11 degrees C). For Lines 2-4, maximum temperature is minimum temperature in the table plus 15 degrees F (9 degrees C).Source: ACI PRC-306, "Guide to Cold Weather Concreting"

Table 2. Recommended Concrete Temperatures. For colder weather, a greater margin in temperature is provided between concrete as mixed and required minimum temperature of fresh concrete in place. For Line 1, maximum placement temperature is minimum temperature in the table plus 20 degrees F (11 degrees C). For Lines 2-4, maximum temperature is minimum temperature in the table plus 15 degrees F (9 degrees C).Source: ACI PRC-306, "Guide to Cold Weather Concreting"

It’s important to make sure concrete has the proper temperature. During cold weather, the concrete mixing temperature should be controlled so that when the concrete is placed, its temperature is not below the values shown in Table 2 for normal-weight concrete. The temperature of concrete at the time of placement should always be near the minimum temperatures. Placement temperatures should not be higher than these minimum values by more than 20º F (11º C)

High concrete temperatures do not offer significantly longer protection time against freezing because heat loss is more rapid when concrete temperatures are higher than ambient temperatures. High concrete temperatures require more mixing water to attain a given slump, increase the rate of slump loss and thermal shrinkage, as well as the possibility of plastic shrinkage cracking because moisture loss through evaporation is greater.

Select the Right Concrete Materials

The use of faster setting cements may improve the rate of hardening of concrete in cold weather. A 10-15º F (5-8º C) temperature rise per 100 lb. (45 kg) of cement occurs from cement hydration. The temperature increase from cement hydration is directly proportional to the cement content of the concrete.

Type III (high-early strength) cement can be used to achieve faster setting time and higher early strength. The principal advantages of Type III cement occur during the first seven days.

Fly ash and other pozzolans and slag cement are used as partial replacements for portland cement. These materials can be used in conjunction with accelerating admixtures to obtain desired concrete performance in cold weather concreting.

The requirements for good results in placing and curing concrete in cold weather are not different from that for other seasons. Concrete should be placed where it is to remain and in shallow layers to allow adequate vibration as well as use windbreaks, cure and protect freshly placed concrete from moisture loss and freezing.

Use the Right Concrete Admixtures

Certain chemical admixtures are beneficial for concrete placed during cold weather. Benefits of using these chemical admixtures in concrete include:

- Reduced water demand

- Improved workability during placing

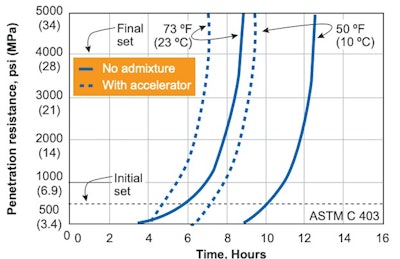

- A faster rate of setting (see Figure 3)

- Increased early compressive strength

- Earlier stripping and reuse of forms

Figure 3. Effect of Concrete Temperature and Accelerating Admixture on Setting Time.Source: Master Builders Solutions

Figure 3. Effect of Concrete Temperature and Accelerating Admixture on Setting Time.Source: Master Builders Solutions

Even in cold weather, contractors should order and take advantage of the benefits provided by synthetic microfibers in a properly proportioned concrete mixture to reduce or limit the formation of plastic shrinkage cracks.

When it comes to selecting a product, you should look for a company that has not only high-quality products but also the technical expertise to assist the entire construction team in the design, production, delivery, placement and curing of quality concrete in cold weather.

Using Master Builders Solutions as an example, accelerating admixture products that provide benefit in cold weather include those conforming to ASTM C 494/C 494M and AASHTO M194, the Standard Specification for Chemical Admixtures for Concrete, Type C, accelerating and Type E, water-reducing and accelerating as well as the requirements for Type C and Type E admixtures in Corps of Engineers CRD-87. In addition, there is a Type E admixture available that can be used to allow the placement of a properly proportioned concrete mixture at ambient temperatures as low as 20º F (-7º C), in conjunction with best concreting practices reducing the possibility of the concrete freezing in its plastic state.

Follow the Proper Curing Methods

As you know, concrete curing is critical to getting the desired long-term properties. Curing is the maintenance of satisfactory moisture content and temperature in concrete during its early stages so that desired properties may develop (see Figure 4). The minimum recommended curing period is seven days. Inadequate curing can cause plastic shrinkage cracking and impair strength development and durability.

Freshly placed concrete in cold weather must be protected from drying so that adequate hydration can occur. Normally, measures must be taken to prevent evaporation of moisture from concrete.

Methods of curing concrete in cold weather include:

- The use of impervious paper and plastic sheets

- The use of membrane-forming curing compounds (for water-based curing compounds follow manufacturer’s directions)

- Water curing/ponding is not recommended in freezing weather

Figure 4. Effect of Curing on Compressive Strength of Concrete.Source: ACI PRC-306, "Guide to Cold Weather Concreting"

Figure 4. Effect of Curing on Compressive Strength of Concrete.Source: ACI PRC-306, "Guide to Cold Weather Concreting"

- Plan ahead for cold weather concrete placements

- Use warm concrete ingredients and accelerating admixtures

- Avoid placing concrete on frozen subgrade

- Prevent concrete from freezing

- Limit rapid concrete temperature changes

With colder weather on the way, it’s important to make sure to follow proper concrete procedures to mixing, placing, and curing concrete. Colder temperatures can have an adverse effect on concrete admixtures and its properties affecting its quality if the proper precautions are not taken. However, by following these tips, successful cold-weather concrete can be achieved on your next cold weather project.

Speak to Your Concrete Supplier

There are a variety of chemical admixtures available, so make sure to adhere to the project specifications or discuss with your local producer or admixture supplier. They will have prior experience with a particular admixture/admixture combination and can help you conduct trial mixtures that best serves your needs.

Cold weather can cause a variety of issues in fresh, hardened, and decorative concrete. However, through the use of heated concrete ingredients, protection of materials and equipment from cold weather, good scheduling, and especially the use of the appropriate chemical admixtures, you can have the strength and durability needed in your concrete this winter.

About the author

Richard Hubbard III, LSSGB, is the senior technical specialist for Master Builders Solutions. He has 45 years of experience in the industry with a focus on concrete admixtures.