Regardless of the season, whether it's fall or spring, weather changes change how a contractor needs to approach cutting concrete. Same-day cutting might be “par for the course” for warmer weather, but the cold delays that work just a bit. That and you need to make sure to use the right blade for the job. Utilizing the wrong blade to cut concrete can prematurely dull it – costing time and money.

Dan Brown of Esch Construction Supply Inc.Esch Construction Supply Inc.

Dan Brown of Esch Construction Supply Inc.Esch Construction Supply Inc.

With December settling in, I took him and the company up on this and connected with Dan for some insight into this seasonal problem.

My concrete saw blade is dulling quicker in the cold. Why?

In order to answer this, we have to start at the beginning of the situation with the cut lines themselves. Placing cut lines in concrete creates a controlled crack in the slab – this adds to the slab’s lifespan, giving it more longevity and requiring less frequent replacement.

Cutting on same day concrete is often par for the course. Concrete placed in the morning may likely be ready for cutting that afternoon. But this changes as the temperature drops. Brown explains: “When you have concrete that is poured in the summer when it’s hot…that concrete is setting up and curing in a timely fashion. As the weather changes, concrete doesn’t cure and set up as fast because of the cold weather – especially in an exterior slab. Without heat, helping cure the concrete, where once you would have used a soft cut blade same-day when you start using that same blade next day, it might not perform and cut as well.”

Esch's Pink Next Day Concrete Diamond-bonded blade.Esch Construction Supply Inc.

Esch's Pink Next Day Concrete Diamond-bonded blade.Esch Construction Supply Inc.

Be Sure & Test

In order to know why a blade might be not cutting as well or dulling quicker than normal, first understand the concrete you’re working with. You likely are already watching the cure and keeping an eye on hydration levels, but the timing from August won’t work as well for a Minnesota’s winter work in February. Monitor and watch the slab. “Any good soft-person is in tune with their concrete, they know what it’s doing and how it’s hydrating,” says Brown.

There are two ways to discern if you’re getting close to ready to cut. First, the step test. If your boot doesn’t leave a depression, you’re getting close. The saw roll test involves rolling the same soft cut saw you plan on using to create control joints onto the slab. No impression? You’re likely ready to start your cut.

Esch's Pro Cut Purple concrete blade.Esch Construction Supply Inc.

Esch's Pro Cut Purple concrete blade.Esch Construction Supply Inc.

You can wear out a soft bonded diamond blade really quickly when paired with a soft (or green) concrete with a soft bonded diamond blade, explains Brown. “If we’re cutting green concrete typically we want to go on a little harder side, like our Purple spec. Conversely, if you use a next-day blade on a really green concrete (a soft bonded diamond blade with soft concrete), it’s going to cut it really well just that your life will be really short. The diamond segment will wear out and you’ll be buying a lot more blades,” he says.

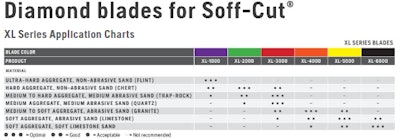

Soff-Cut color spectrum of blade color to materials.

Soff-Cut color spectrum of blade color to materials.

Esch Supply makes a line of blades in a range of sizes. Their Purple blade, known as their Esch Pro Cut, follows the industry-standard color spectrum set out by Soff-Cut from the 1980s. Following suit, the company has come out with a soft-bonded diamond Pink blade specific to Esch for next-day cutting in the warmer weather when concrete is cured and hard.

“In colder temperatures, you’re probably going to want to use a Purple even the next day,” says Brown.

Either over the phone or onsite, Esch Supply includes a full delivery staff and sales reps willing to help diagnose the problem. While it’s often incorrect timing or using the wrong blade at the wrong time, they’ll help you get it dialed in and you back to cutting clean, controlled joints.

Not to mention minimizing the potential financial hit of running through blade after blade.