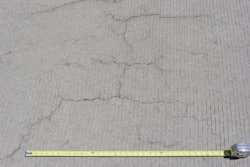

Excessive moisture in construction materials like concrete, framing lumber, sheet rock, etc., can be a major factor behind any number of issues - let alone negatively impact the safety, quality, and efficiency of the work. Combating this has been moisture meters and similar instruments. However, contractors aren't of the woods yet. Expect project delays, downtime, and even safety risks if using the wrong device for the job or it hasn't been properly calibrated.

Some of the problems due to an improper moisture management can cause concrete to improperly cure, adhesives or mastics can come loose, and even lead to mold, corrosion, structural deterioration, chemical breakdowns, etc.

Learn More

Discover ways to prevent critical problems and protect concrete structures from deterioration by avoiding issues due to excessive internal moisture and other harmful chemicals with this FREE white paper — Moisture in Concrete.

Partnering with an expert in moisture measurement and composition analysis can be essential to ensure the safety and performance of products and processes.Kett

Partnering with an expert in moisture measurement and composition analysis can be essential to ensure the safety and performance of products and processes.Kett

To avoid these complications, contractors should look for precision, a device designed to meet the application's requirements, be accurate, and be able to provide repeatable results.

“Without moisture measurement, contractors can make serious, even dangerous mistakes with the drying and curing times of concrete, adhesives, mastics, and other materials,” says John Bogart, Managing Director of Kett US, a manufacturer of a full range of moisture and organic composition analyzers.

With an accurate measurement analysis of moisture management for construction vital, consider reaching out for help. Partnering with an expert not only for guidance on instrument selection and calibration but for training and continued consultation can put that one extra tool in the toolbox.

Manufacturers with expertise would not only help match application to the instrument but figure out any mistakes being made. "The first step is research to determine the most common types of instrument usage errors in the industry, so we can take corrective steps to improve overall safety and performance,” says Bogart.  Because industrial settings can be harsh, the OEM designs instruments that can endure the rigors of the field as well as the wear and tear of production.Kett

Because industrial settings can be harsh, the OEM designs instruments that can endure the rigors of the field as well as the wear and tear of production.Kett

He and his team at Kett reviewed independent studies to better understand the issues at hand. Results indicated that:

- Contractors could not find the appropriate moisture measurement or composition analysis instruments for their specific type of production - they relied on analyzers that did not provide the required accuracy, consistency, or repeatable results

- Some instruments failed due to abrasive wear and tear or exposure to harsh conditions - extended exposure to moisture, salts, or chemical solvents, for example, can accelerate corrosion, breakdown, and the need for replacement

- Contractors reported they often did not have enough support from suppliers to evaluate, install, and calibrate the instruments or train their personnel on proper operation - errors occurred when employees improperly handled and used the instruments, particularly when they had unanswered questions

From this and their 40+ years in engineering and operation, Kett developed a "Total Care Solution Package" to aid contractors in identifying proper instruments, help with calibration, on-site training, and continued support. The company also offers performance guarantees, warranties, and a quick turnaround with repairs. The company also provides a loaner to keep construction moving along.