Looking back at 2017, and having just come back from the World of Concrete after missing a year. I was one of the 58,222 registered professionals and 1547 Exhibitors who were impressed with the turnout, the exhibits, and how far our industry has stretched, now able to present ourselves as a maturing industry, not just a niche market.

For a strong foundation, and to grow upward, we need to add more bricks and mortar every year…..and polished concrete floors! In a satisfying turnaround, we are starting to see other industries and niches looking to see where they might fit in Our Industry – polished concrete. How’s that for a change?

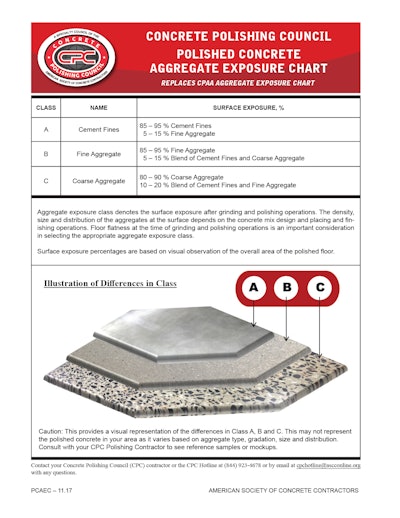

During an industry sponsored get together the second night, Chad Gill (President of the CPAA as it transitioned into being the Concrete Polishing Council, a Specialty Council of ASCC), and Todd Scharich, Director of Membership for ASCC, announced the creation of new standards for the industry. Anytime I hear “new standards” my normal reaction is to cringe, but in this case, I was pleasantly surprised in how they made sense. Along with providing a greater sense of consistency, order and professionalism to our industry. In my initial reaction, I think I had Todd questioning whether I was going to vocally be a pain in the rear, and he didn’t even know me well yet. In reality, I am absolute supporter of the updated, and sensibly refined AGGREGATE EXPOSURE CHART and the POLISHED CONCRETE APPEARANCE CHART.

For what may be a first for our industry, these guidelines provide consistent and understandable direction, they aren’t influenced by one vocal group or company, and they are fair and repeatable. Guidelines shouldn’t be written in a manner that they favor a select group, chemical or tooling; nor should they make it hard for all contractors to follow… nor to do so profitably. To learn more about the changes, please read Jim Cuviello’s article, “Understanding the New Polished Concrete Appearance Chart”, which appeared in the December 2017 issue of Concrete Contractor, page 68. It can also be found online at https://www.forconstructionpros.com/concrete/article/20983634/understanding-the-new-polished-concrete-appearance-chart

Changes

Sometimes we fight, struggle and drag our feet when changes occur. If we do not understand them, or if they go against our training, education and knowledge, we tend to fight them. True not all changes are positive, but to be an intelligent and successful businessperson you must at least entertain them and thoroughly investigate them. If after taking these steps, and you still can’t embrace them, then at least you know how to position yourself against them. Know your competitor as well as you know yourself, maybe even better, and you will survive and thrive.

What changes have we seen in the past one to two years? Are we asking about processes, or are we talking about paradigm shifts in who and what our markets are? If we’re looking at processes, then look no further than Three Step Polishing processes. Do they work? Going into our third year I know that I stand behind our Clarity Enhancing System almost more than anything else I’ve ever been part of. That said, you need to understand these systems and what manufacturers are saying or implying. Is it truly a Three Step System for delivering salt n pepper day in and day out, from beginning to end? Or is it a Three Step Polishing System where prep and/or grinding stages are additional? Research. Question. Know what your true costs of chemicals, tooling and labor will be before you jump in feet first without a safety line.

What about paradigm shifts?

It’s unfortunate that a potentially negative stigma exists regarding growth. Being a more mature market, the concern is that other companies, and maybe industries, will want to come and play in what you considered to be your own backyard. You hustled, you took risks and you created something for yourself, your family and your employees, but now new kids are showing up on your block.

Who are these new kids? What is this market opportunity? You’ll notice that I slipped in opportunity? I didn’t say that these new kids wouldn’t leave their back door open, allowing you the opportunity to slide into their market.

If you haven’t figured out, I’m talking about the Contract Cleaner, the Jan San industry. You have successfully sold the merits of polished concrete into their markets; say the grocery industry for example. Well, you were so successful penetrating their market, that to grow and remain profitable, even survive, they must invade yours. Now instead of competing against other classic polishing contractors who utilize heavy grinders with metal / hybrid / resin matrixed diamonds, you may be competing against auto scrubbers and burnishers with scrubbing and polishing pads.

When you saw those whirly bird guys polishing concrete while visiting the outside lots, was your water glass half empty or half full? Did you see an opportunity or more competition? I’m not talking the polish of years past when they excelled at burning the slabs, I am talking ride-on equipment equipped to utilize the same diamonds and densifiers that you do. It all depends on what services you want to offer, how you are capitalized, and whether you want to specialize in local, possibly more moderately sized projects versus staying on the road; traveling for the Big Bucks to keep the equipment busy?

Open your eyes, look around and determine what you want to do, and are comfortable and capable of investing in- look at your market with a magnifying glass and turn over ever stone of knowledge seeking opportunities. Changes and opportunities abound if you are serious and look for them. Know more than your competition. Know what you can do, and want to do. Understand the changes such as the new CPC Aggregate and Appearance standards. Do you know how Distinction of Image (DOI) differs from Gloss? When you read the new Polished Concrete Appearance Chart do you know what Haze is when the standard requires a Haze reading of less than 10 for all four levels? Personally, I had to ask a friend, so now I know that is a simple setting on the DOI Meter. If you’ve questions please contact me, or call John Imbault of IMBOTEC at 866-462-6832. They are the Master distributors of the Concrete Clarity Meter that is a Dual Read Meter for Gloss and DOI, and provides the Haze calculation.

The industry constantly changes, constantly surprises. We never thought we’d see the ability to provide clarity in fewer steps, any more than we thought we’d see five different Shades of Gray dye being offered. Ride-on with diamonds? Contract Cleaners coming into the Polishing Industry? The vortex is open both ways, why not take a page out of their book and look for opportunities in their world. Have a great 2018.

Ed. Note: Peter Wagner is Director, Supporting Products Development for Curecrete Distribution, the creators of RetroPlate 99, the first chemical densifier for polished concrete, and CreteClean Plus, the first polished concrete cleaner. Wagner has been involved in the flooring industry for over 30 years, focusing on polished concrete since 1999. He has written over 40 articles on the industry since 2006, and frequently delivers seminars at industry events. He can be reached at [email protected].