When it comes to grinding and polishing concrete floors, there are many variables that affect quality of the floor finish and how fast you can finish the job but it all starts with selecting the right tools for the specific project, and your diamond tooling efficiency determines your bottom line.

The initial cut is always the most time consuming, especially when you have to remove thick coatings. In some cases contractors can start with metal bond tools but thick coatings often require a more aggressive step like PCD tools, i.e. tools with one or two poly-crystalline diamond segments, with or without sacrificial bars or a metal button. This is what Robles Concrete Services, a flooring contractor from Georgia, used to remove the thick coating on their most recent project for Resilux America, a PET-plastics manufacturer with headquarters in Pendergrass, Ga.

Resilux chose a honed and dyed concrete finish as part of their plant renovations. They contracted Robles Concrete Services and the first plant renovation has just been completed. The 44,000 square foot building was previously owned by a construction equipment company, and there was a lot of grease embedded in the concrete, plus some 13,000-square feet of flooring had a 5mm thick coating to be removed. A real pain throughout the entire project were the 200-plus bolts sticking out on the floor, where shelving used to be, and damaging tools if not properly hammered or ground down one by one.

Robles Concrete used LAVINA grinders – LAVINA 32-inch, LAVINA 30 inch (propane) and LAVINA 25-inch. The first step was with PCD diamond tooling from Superabrasive. The tools worked aggressively but left deep scratches, so Robles Concrete had to continue grinding with a 14 grit metal bond diamonds. Superabrasive’s QuickChange tools are offered in separate bonds for hard (red), super hard (gold and white), medium (grey) and soft (yellow) concrete.

For the tooling optimal efficiency, it is important to check the floor hardness before selecting a bond. Robles Concrete used the Red tools for hard concrete made of soft bond to cut fast. They grinded the floor with 30, 50 and 120 grit, and switched to Superabrasive’s Calibra ceramic discs, 100 grit (3-inch Velcro backed). Calibra are ideal for removing scratches after metal steps, and they did a great job refining the scratch pattern.

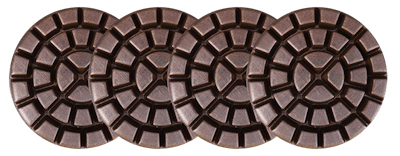

The sections of the floor where no coating had to be removed, were processed much faster. Robles Concrete started with Superabrasive’s HD Copper discs, which cut the concrete really fast without leaving deep scratches. The copper discs have to be used wet, and an auto scrubber was cleaning diligently after each pass. Next steps were 200 and 400 grit HD resin pads (dry), after which they put down Prosoco’s densifier and Gem tone dye.

Robles Concrete ran one final step with LAVINA 36-inch propane burnisher (LB36G-S) and ShinePro Buff pads. ShinePro Buff is a 3,000 grit diamond pad designed for micro polishing and mechanically cleaning sealed and non-sealed floors, and is part of Superabrasive’s ShinePro line of diamond screens and pads for floor restoration and maintenance. It improves the floor shine without removing the sealer or causing orange peel effect.

The next plant renovation for Resilux is starting in the 2nd quarter of 2016 and includes the same floor finish as the first plant. Fortunately, there are no more coatings to be removed and Robles Concrete expects a faster project turnaround time. They will be using again LAVINA grinders with Superabrasive’s HD Copper discs (wet grinding), starting with 50 grit, 100 and 200, color and densify, and finish with Superabrasive’s V-Harr premium polishing pads, 400 grit.

Ed. Note: This article was supplied by Superabrasive Inc., manufacturer of LAVINA equipment and diamond tooling – [email protected]

www.superabrasive.us. The concrete contractor who performed this is Robles Concrete Services, www.roblesconcreteservices.com.