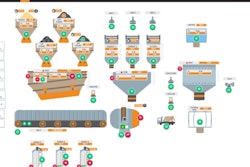

![Sysdyne Cloud Batch 60bf8131234d6[1]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2021/06/Sysdyne_Cloud_Batch.60bf8131234d6_1_.60c77e6a37d3a.png?auto=format%2Ccompress&q=70&w=400)

Sysdyne Technologies' Pioneer Cloud Batch brought the batch software online and made it visible and accessible by multiple users. Simply logging onto ConcreteGO.com, plant managers, IT support staff, quality control managers and regional executives can access batch controls anywhere at any time using any device to monitor the batch cycles, make mix design changes as needed and address loading issues without interfering with the actual concrete loading cycle. It helps speed up the batch process, make sure the mixes are properly adjusted as needed and reduce the material cost by tightly controlling the material usages.

Cloud Batch fundamentally changed the perception of batch integration. Rather than following the antiquated Universal Link protocol to integrate batch controls with dispatch or ERP software, now the batch control can be integrated using Open API (Application Programming Interface).

The Open API eliminates the limitation of data exchange imposed by traditional data exchange protocols and allows the users to gain more insights of their operations. Pioneer Cloud batch is the first batch control in the market that shares the same database with concrete dispatch - ConcreteGO® . Now that concrete producers can manage mixes, materials, customers, projects, orders, tickets in one single place without downloading or uploading data. The inventory can be accurately tracked in real time.