Human error is something that construction workers and managers need to always be aware of in dangerous situations. Limiting the risks associated with human error not only increases the efficiency of task completion but also bodily safety. An emerging technology sector is trying to redefine safety protocols in construction: autonomous vehicles. Rather than replacing living, breathing workers with electronic robots, these self-functioning devices are designed to alleviate workplace pain points and complement essential construction workers.

By design, autonomous vehicles need to be connected to a network to interact and engage with the environment. However, some aspects are at play holding back the widespread adoption of autonomous apparatuses. Part of the issue is in the approach, while wireless challenges and physical obstacles still cause problems on construction sites for autonomous vehicles like heavy-duty or medium-duty trucks. These are the three key components that are delaying the eventual ubiquitousness of autonomous vehicles on construction sites.

Right Idea, Wrong Approach

5G has done a great job marketing itself. Don’t make the mistake of thinking a carrier network built for your smartphone will work for machine autonomy. Smartphones require fast download speeds at the expense of upload capacity. Connected jobsites, on the other hand, have the opposite need. They need upload capacity with far less download capacity. Mesh networks, however, have equivalent upload and download capacity. Using carrier LTE can often feel like you’re competing with the general public for network capacity. That is, if you even have cellular coverage to begin with. When you have a contract for a job, you need to know you have systems to help you be as efficient and productive as possible. Contractors’ reluctance to implement autonomy has less to do with understanding potential benefits and more to do with a lack of confidence they have all the supporting technologies in place for it to be successfully deployed. The answer is a Mesh network. When you own your own network, you can control both the coverage and capacity of that network without the worry of third party users competing for capacity. Machine-to-machine (M2M) communications ensure you have the coverage you need when you need it.

Coverage Challenges

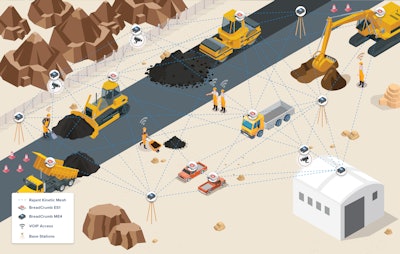

Areas that are not yet equipped for maintaining a wireless network — whether the network is 5G, mesh or otherwise — can complicate and hold back autonomous vehicle deployment. The operations needed to handle data backhauling and power the moving devices are as important as the robots themselves. Creating a robust and reliable communication infrastructure enables communication over longer distances and reduces frequency output to help bring broadband speeds up. With Rajant, for example, network nodes are placed around the jobsite to create an aggregate of longer-range communications than are capable with traditional Wi-Fi or serial networks. The nodes act as repeaters, whether they are fixed or mobile, and communication bridges in areas where communications may be weak or incomplete in coverage. Distributing the network signals through these nodes builds a connected digital ecosystem for the machines and workers involved.

Obstruction of Other Machinery

Whether it’s a massive Komatsu truck, like the 980E-4, or a wall built at the construction site, physical obstacles can interrupt wireless networks, making it challenging and costly to provide blanketed network coverage on the jobsite. This is one of the big reasons construction managers are hesitant to deploy many autonomous vehicles on their sites. Suppose large, unmanned machinery is roaming around and loses connection to the wireless center or network node powering it. In that case, people could be seriously injured, and other equipment may very well be destroyed too. Autonomous heavy-duty and medium-duty trucks and trailers can be detrimental to each other and to smaller devices. Having autonomous vehicles working in congruence allows for a safe and efficient connected jobsite.

Moving Toward a Fully-connected Jobsite

If you want to increase efficiency and productivity on your jobsite, your focus must first be on improving your jobsite connectivity. You need to ensure you have coverage, capacity and connectivity sorted to realize gains from specific technology applications. Once that is in place, it is exponentially simpler to implement applications and achieve the high return on investment you are aiming for, with tele-remote and autonomy as the pinnacle. Let’s also not forget the importance of safety. It is potentially dangerous for workers doing their jobs at the same locations autonomous equipment is running. Reliable communications are the single biggest factor in providing worker safety. A connected jobsite in and of itself brings efficiency and much-needed safety to the forefront. When you combine safety with productivity and efficiency, you have the winning combination to drive increased profits.

![Vortex Advantage Boom Truck[21]](https://img.forconstructionpros.com/files/base/acbm/fcp/image/2022/08/Vortex_Advantage_Boom_Truck_21_.630ccaeba8b50.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)